Pseudomonas for producing lipopeptide surfactant and purpose

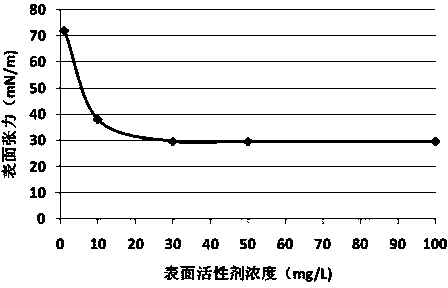

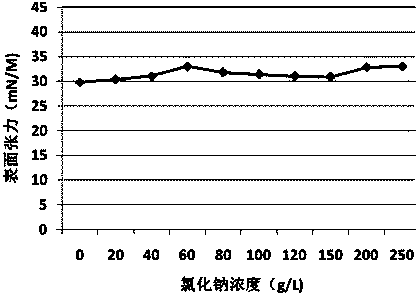

A Pseudomonas and surfactant technology, applied in the field of Pseudomonas, can solve the problems of unsuitable industrial production, few types of lipopeptide surfactants, and low output, and achieve good emulsifying activity and good salt resistance , the effect of reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Example 1. strain screening and identification

[0090] The bacterial strain Pseudomonas.sp.D4 provided by the present invention is isolated from the middle soil of Aiding Lake in the southeast of Turpan City, Xinjiang Uygur Autonomous Region, China. Add the newly collected soil samples into sterile physiological saline, shake on a shaker at 220r / min for 2h, and after standing still for 30min, take 10ml of the supernatant and inoculate it into a 250ml Erlenmeyer flask containing 50ml of enrichment medium. min, cultured with shaking for 3 days, and harvested the culture medium.

[0091] The harvested culture solution was diluted with sterile saline for 10 5 , 10 6 , 10 7 For each dilution, take 0.1ml of the bacterial solution and apply it to the enrichment medium on the plate, and culture it statically at 30°C for 4 days. Colonies with oily spots on the plate enrichment medium were further separated and purified by streaking on the LB medium plate, and a single col...

Embodiment 2

[0097] Example 2. Bacterial strain cultivation

[0098] 2.1 Seed culture

[0099] Pick the next ring of D4 strain from the cultured slant medium, inoculate it in a 250ml baffle shaker flask equipped with 50ml seed medium, and culture it with shaking at 28°C and 200rpm / min for 16 hours to obtain a seed culture solution.

[0100] 2.2 Fermentation culture

[0101] Put the seed culture solution prepared in step 2.1 into a 250ml baffle shaker flask with 50ml of fermentation medium according to the inoculum amount of 2% (V / V), and culture it with shaking at 28°C and 200rpm for 72 hours to obtain D4 strain fermentation liquid.

[0102] 2.3 Detection of fermentation broth

[0103] After diluting the fermented liquid prepared in step 2.2 4 times with distilled water, centrifuge at 8000 r / min and 4°C for 20 min, and collect the fermentation supernatant and cell precipitate respectively. The precipitated bacteria were prepared into a bacterial suspension using distilled water, and ...

Embodiment 3

[0105] Embodiment 3. Biosurfactant preparation and processing

[0106] 3.1 Biosurfactant preparation

[0107] Take 120ml of the fermentation broth prepared in step 2.2, dilute it 4 times with distilled water, centrifuge at 8000r / min, 4°C for 20min, remove the bacteria, and adjust the pH of the collected supernatant to 2.0 with concentrated hydrochloric acid, and a flocculent precipitate appears , stand overnight at 4°C. 10000r / min, centrifuge at 4°C for 30min, collect the precipitate, and wash once with hydrochloric acid of pH 2.0, then adjust the pH value of the precipitate to 7.0 with 1mol / L NaOH solution, and freeze-dry to obtain the surface activity of light brown loose solid crude product F 1 2.57g, the yield is 21.4g / L.

[0108] Extract the crude F 1 Three times, the obtained organic phases were combined and dried at 60° C. to obtain 20.548 g of purified sample F with a yield of 4.57 g / L.

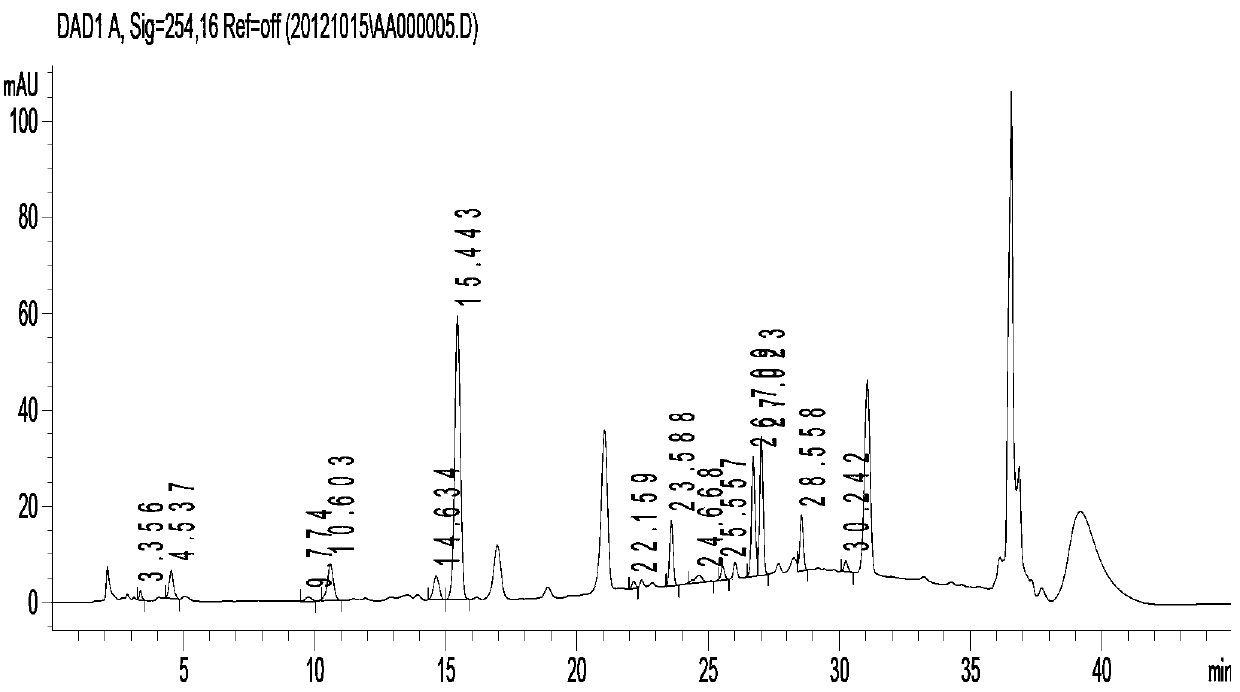

[0109] 3.2 Sample hydrolysis

[0110] Take the F prepared in step 3.1 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com