Dry soft electrode based on direct-current magnetron sputtering technology and manufacturing process thereof

A DC magnetron sputtering, dry technology, applied in the field of medical devices, can solve the problems of patients or subjects tingling, skin and blood penetration, needle array penetration, etc., to achieve good chemical stability, no The effect of pressure and thickness controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific embodiments.

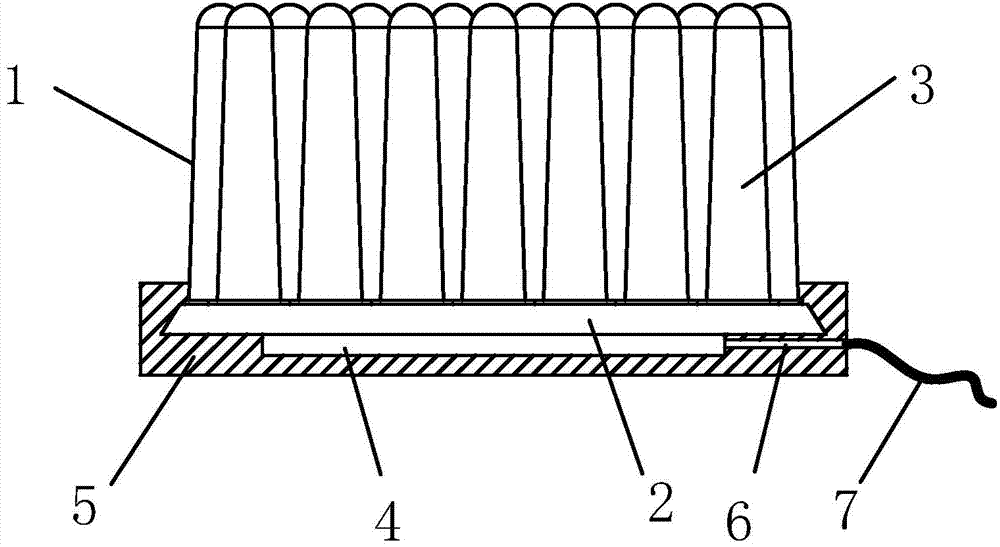

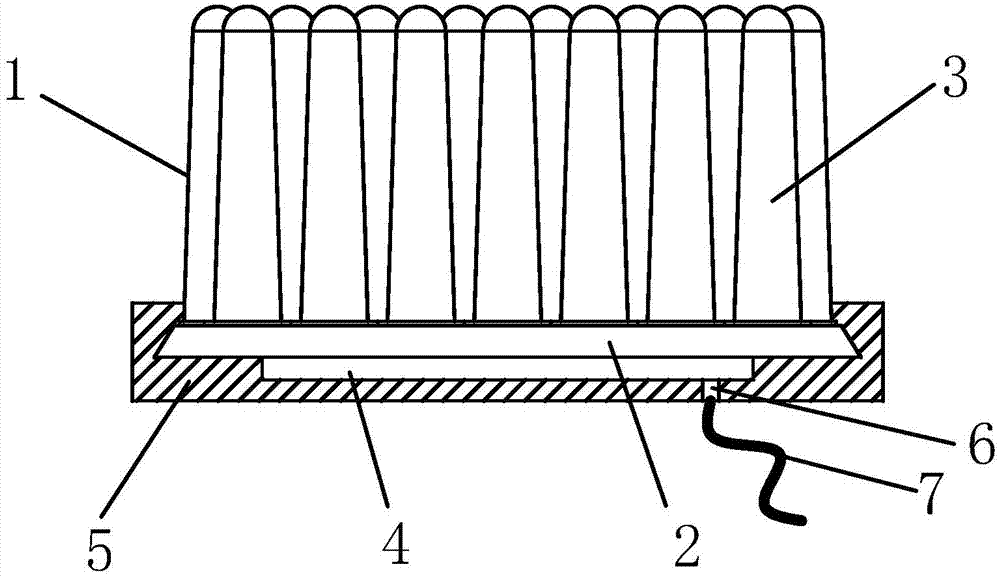

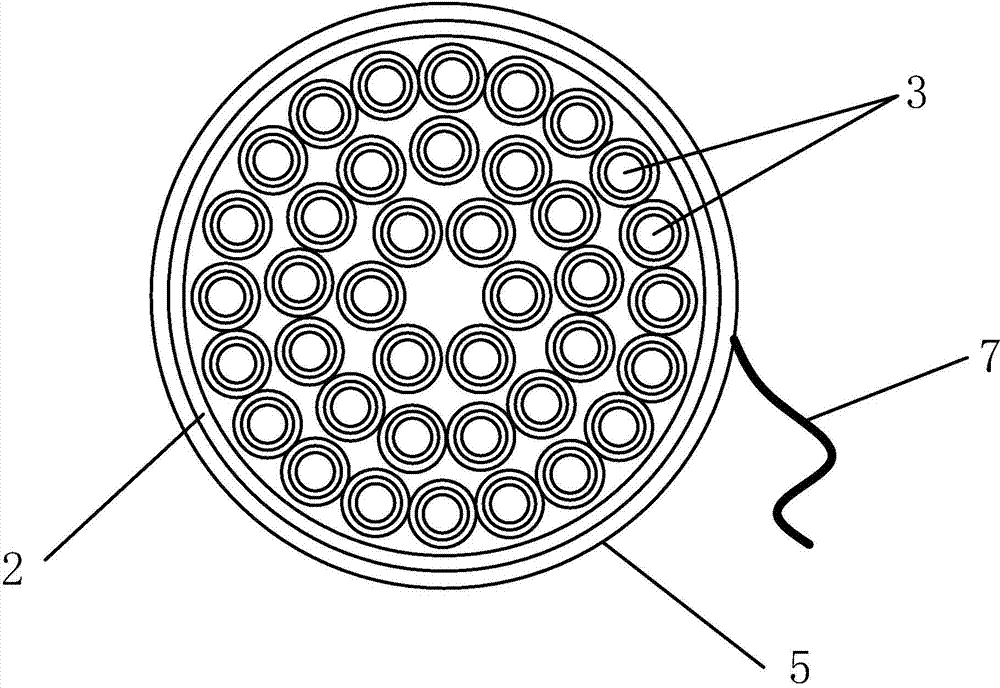

[0030] like Figure 1-3 Shown: a dry soft electrode based on DC magnetron sputtering technology, which includes a base 1, the base 1 includes a base 2 and several electrode needles 3 above the base 2. The base 1 base 2 is circular, and the electrode needles 3 are evenly arranged on the base 2 . The electrode needles 3 may be closely adjacent to each other, and there may also be a certain gap between the electrode needles 3 . The needle head of the electrode needle 3 is circular or arc-shaped. The electrode needle 3 is in the shape of a thin needle head and a thick tail. The base 1 is made of silica gel, rubber or polyurethane, and the material is soft. The bottom of the base 2 is provided with a conductive sheet, and the conductive sheet 4 is provided with a conductive wire 7. The material of the conductive wire 7 can be a variety of materials such as: copper, copper ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com