A method to improve mno in electrodes x Method for Catalyst Oxygen Reduction Activity

A catalyst and electrode technology, which is applied in the field of improving the oxygen reduction activity of MnOx catalysts, can solve the problems of ORR activity changes and changes, and achieve the effects of improving oxygen reduction activity, reducing impact, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

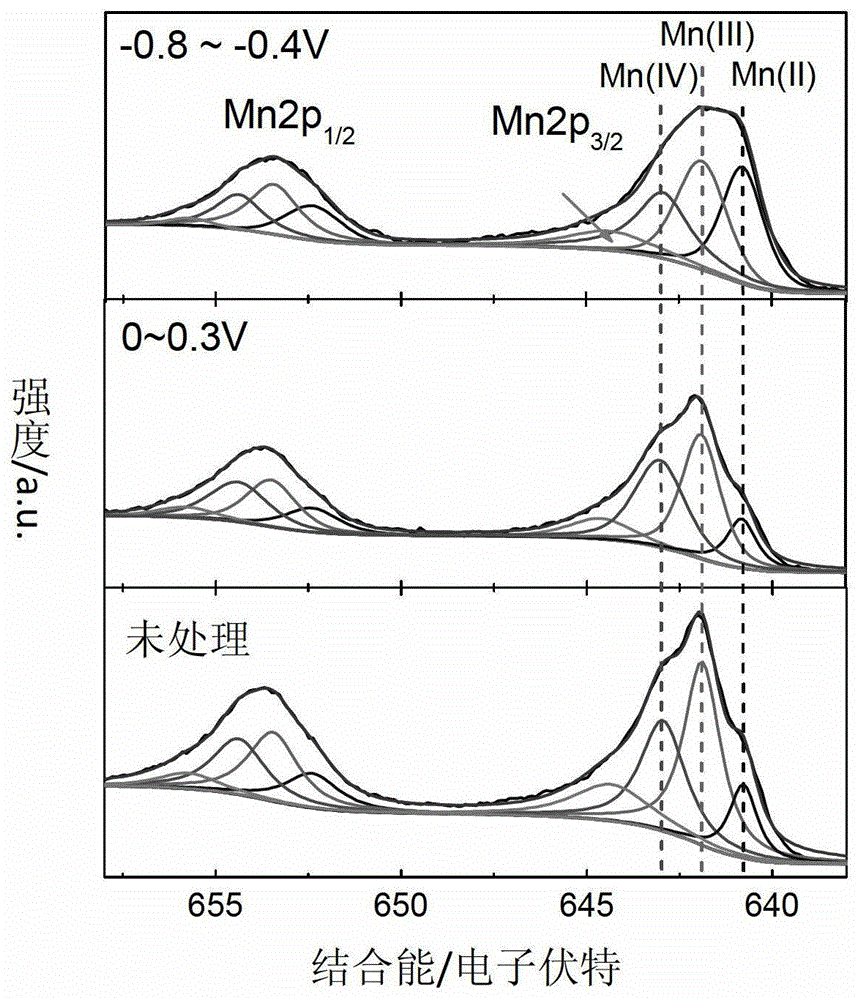

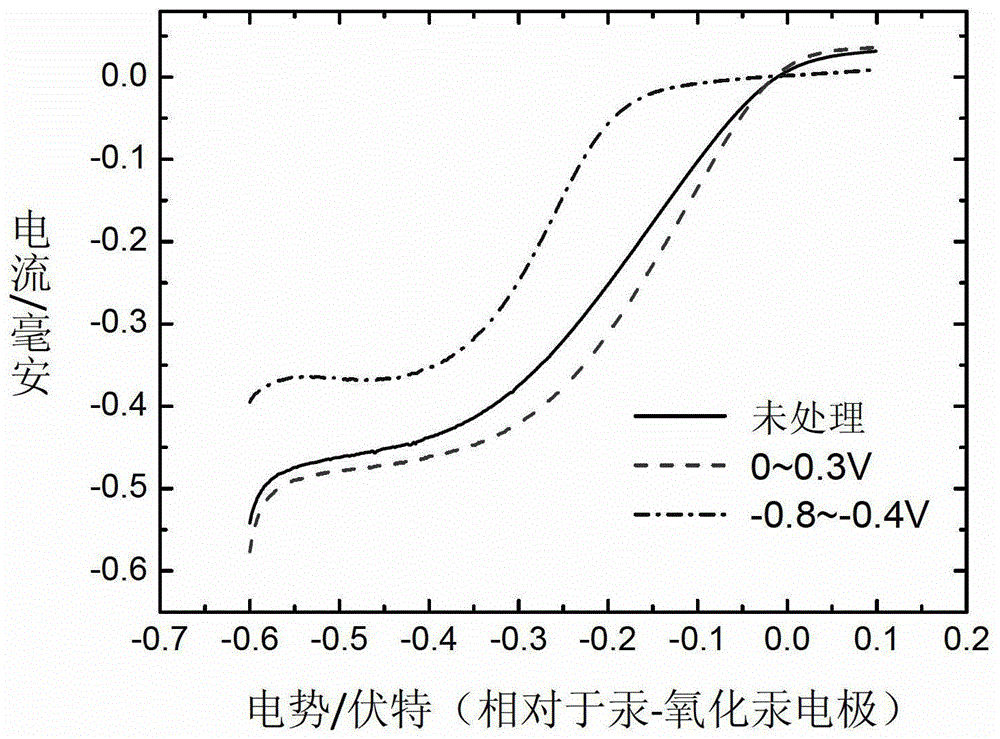

[0027] Weigh 30mg of prepared MnO x As a catalyst, 2 mL of ethanol and 67 mg of Nafion emulsion with a mass fraction of 5% were sequentially added, and the slurry uniformly dispersed by ultrasonic was coated on the surface of a Pt electrode to obtain a working electrode. Take the Pt sheet as the counter electrode and the Hg / HgO electrode as the reference electrode, between 0-0.3V with 10mVs -1 Cyclic voltammetry scan (20 circles) at the scanning speed, the electrode rotation speed is 1600rpn, the half-wave potential of the ORR polarization curve shifts about 30mV, MnO x The catalytic activity for ORR was significantly improved, such as figure 2 shown.

Embodiment 2

[0029] Weigh 30mg of prepared MnO x As a catalyst, 2 mL of ethanol and 67 mg of Nafion emulsion with a mass fraction of 5% were sequentially added, and the slurry uniformly dispersed by ultrasonic was coated on the surface of a Pt electrode to obtain a working electrode. With the Pt sheet as the counter electrode and the Hg / HgO electrode as the reference electrode, the ORR catalytic activity was significantly improved after maintaining the potential at 0.2 V for 5 min.

Embodiment 3

[0031] Weigh 30mg of prepared MnO x As a catalyst, 2 mL of ethanol and 67 mg of Nafion emulsion with a mass fraction of 5% were sequentially added, and the slurry uniformly dispersed by ultrasonic was coated on the surface of a Pt electrode to obtain a working electrode. With Pt sheet as the counter electrode, Hg / HgO electrode as the reference electrode, with 1mVs -1 The scan rate is linearly scanned within the potential window of 0.0-0.4V, and its ORR catalytic activity is significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com