Semi-wet static gas dedusting and purifying device

A gas dust removal and purification device technology, applied in electrostatic separation, chemistry, heating methods, etc., can solve the problems of increasing indoor particle concentration, noise, excessive humidification of indoor air, etc., to reduce the risk of influenza infection, efficient capture, gas small resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

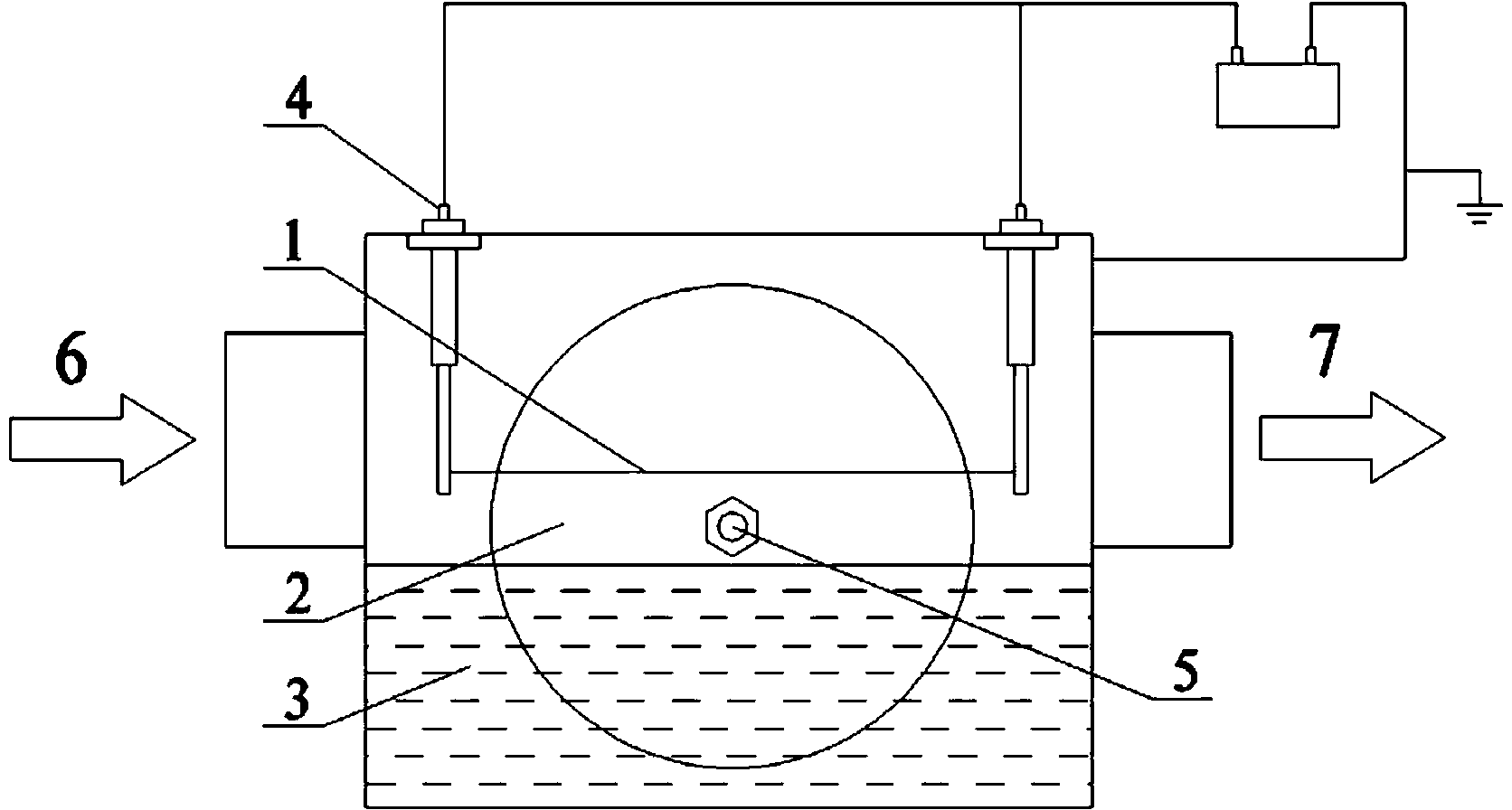

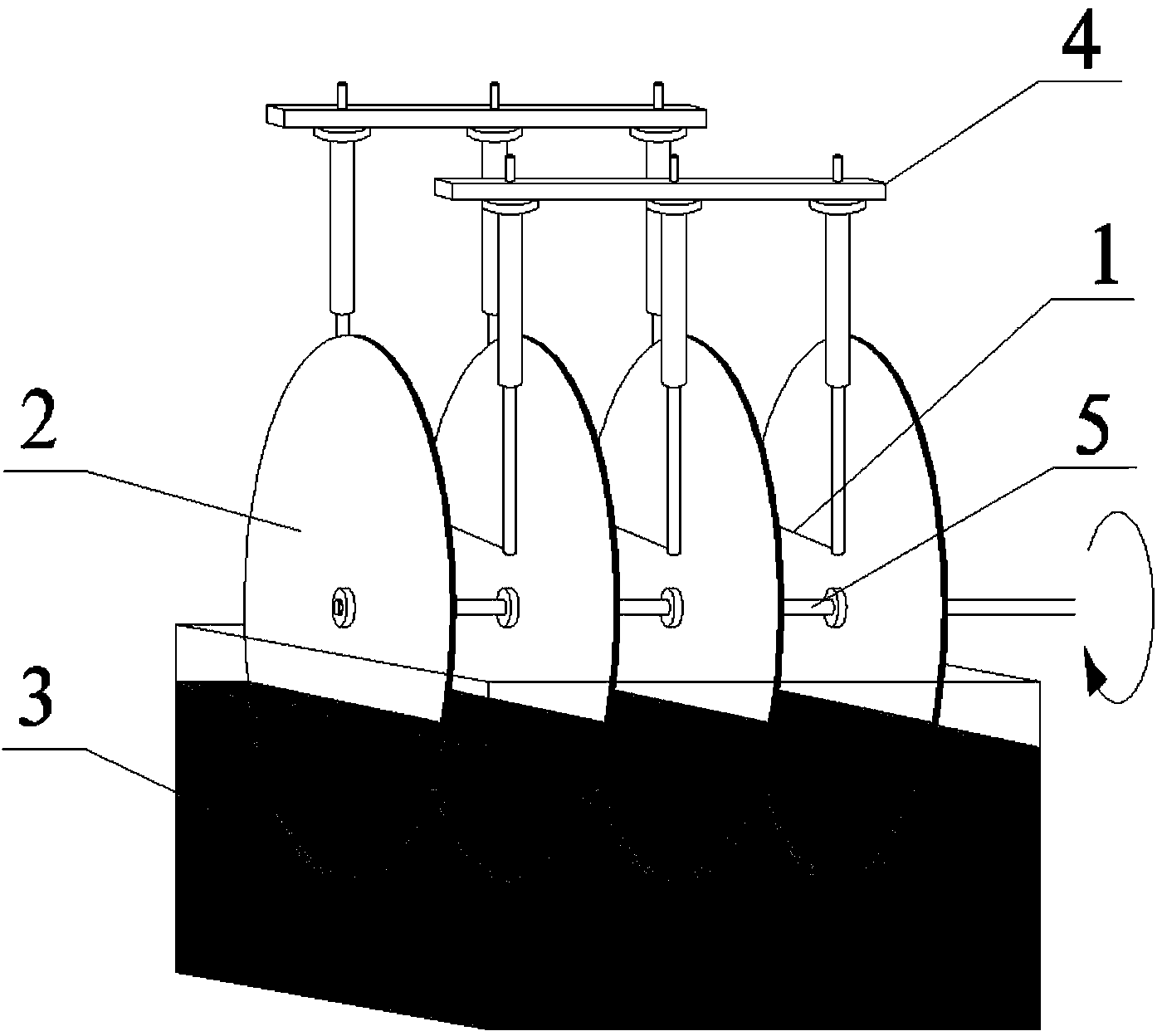

[0021] Take 10 pieces of aluminum discs with a diameter of 20cm as dust collectors, fix them on a transmission shaft, the diameter of the transmission shaft is 1cm, and the distance between each disc is 2cm, and set 9 metal wires with a diameter of 0.2mm as corona electrodes. Between the dust collectors, the wire direction of the corona electrode is parallel to the direction of the dust collector disk, and the distance from the dust collector disks on both sides is equal. The corona electrode is connected to the positive pole of the high voltage power supply, and the dust collector is connected to the high voltage The negative pole of the power supply and the negative pole of the high-voltage power supply are well grounded. The output voltage is 20kV. The lower half of the dust collector is immersed in the liquid surface of the water tank. The solution in the water tank is 1% benzalkonium bromide solution. A gas flow box is arranged on the upper part of the water tank, and the ...

Embodiment 2

[0023] Take 20 pieces of stainless steel discs with a diameter of 10cm as dust collectors, fix them on a transmission shaft, the diameter of the transmission shaft is 1cm, and the distance between each disc is 0.8cm, and 19 metal wires with a diameter of 0.2mm are set as corona electrodes. Between the dust collectors, the wire direction of the corona electrode is parallel to the direction of the dust collector disk, and the distance from the dust collector disks on both sides is equal. The corona electrode is connected to the negative pole of the high voltage power supply, and the dust collector is connected to the high voltage The positive pole of the power supply, the positive pole of the high-voltage power supply is well grounded, the output voltage is 30kV, the lower half of the dust collector is immersed in the liquid surface of the water tank, the solution in the water tank is 1% sodium pyrithione solution, and the liquid surface is 5mm away from the edge of the transmissi...

Embodiment 3

[0025] Take 8 pieces of aluminum discs with a diameter of 5cm as dust collectors, fix them on a transmission shaft, the diameter of the transmission shaft is 8mm, and the distance between each disc is 1cm, and set 19 metal wires with a diameter of 0.2mm as corona electrodes. Between the dust collectors, the wire direction of the corona electrode is parallel to the direction of the dust collector disk, and the distance from the dust collector disks on both sides is equal. The corona electrode is connected to the positive pole of the high voltage power supply, and the dust collector is connected to the high voltage The negative pole of the power supply, the negative pole of the high-voltage power supply is well grounded, the output voltage is 18kV, the lower half of the dust collector is immersed in the liquid surface of the water tank, the solution in the water tank is 1% potassium sorbate solution, and the liquid surface is 5mm away from the edge of the transmission shaft. A ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com