Portable Laser Rust Remover

A laser derusting and portable technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of non-professional technicians who are not easy to operate, inconvenient to maintain and move, and limited application range, so as to achieve reasonable equipment structure design , high precision and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

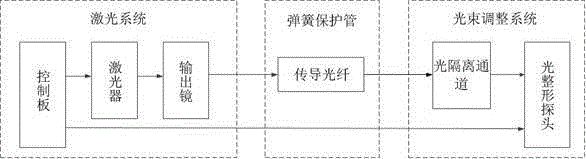

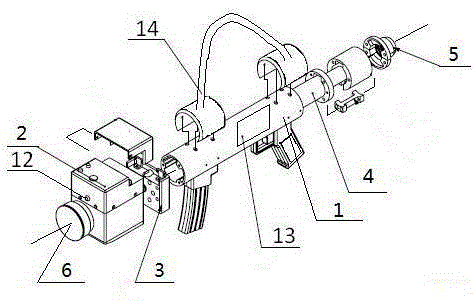

[0038] Depend on Figure 1~5 It can be seen from the illustrated embodiment that it includes a laser system, a beam adjustment system and a guide fiber; the laser system and the beam adjustment system are connected through a guide fiber;

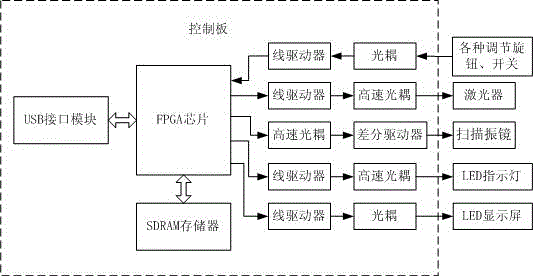

[0039] The laser system includes a main shell with a strap, a laser located in the main shell, a control board and an output mirror; the corresponding output terminal of the control board is connected to the data interface of the laser; the output end of the laser is provided with an output mirror;

[0040] The light beam adjustment system includes an optical isolation channel and a light shaping probe; the optical isolation channel includes an optical channel housing 1 with a handle and an isolation sleeve 4 arranged in the optical channel housing 1, and the optical channel housing 1 One end of one end is provided with sn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com