Device for preparing graphene through large-scale electrochemical efficient stripping

A graphene and electrochemical technology, which is applied in the field of large-scale electrochemical stripping and preparation of graphene, can solve the problems of graphene honeycomb lattice structure damage, graphene is not suitable for large-scale production, and graphene products are expensive , to achieve the effect of easy construction, simple structure and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

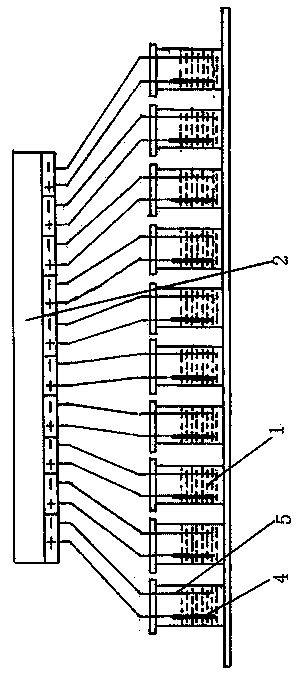

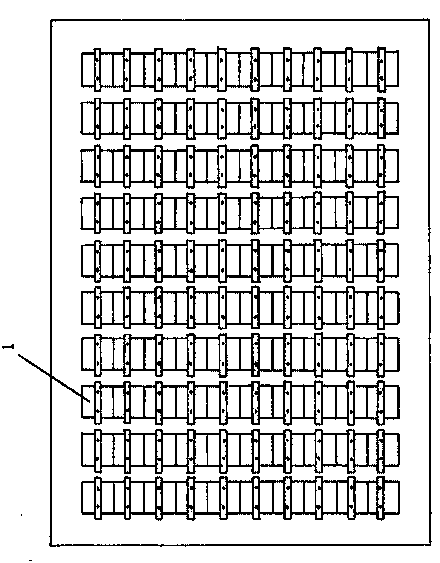

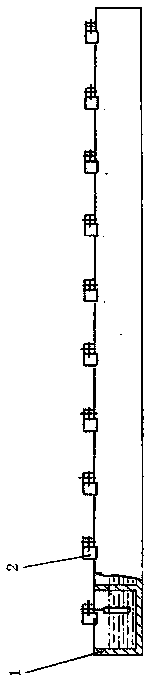

[0034] Embodiment: the large-scale electrochemical high-efficiency stripping of this example prepares the device of graphene, as Figure 5 , Image 6 , including electrolytic cell 1, the electrolyte in the electrolytic cell is K 2 SO 4 electrolyte. The upper end of the electrolytic cell is provided with a fixed rod 2, and the upper surface of the electrolytic cell is provided with a positioning block 12, and the fixed rod is fixed in the positioning block. A pair of metal blocks 3 are fixed on the fixed rod, and the metal blocks are fixed on the fixed rod by fixing screws 11 . The two metal blocks are respectively connected with a graphite working electrode 4 and a platinum wire electrode 5. The upper end surface of the graphite working electrode is provided with a jack, and a tungsten wire 10 is inserted through the jack, and the upper end of the tungsten wire is fixed in the metal block. Graphite working electrodes and platinum wire electrodes extend into the electrolyti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com