Method for preparing graphene material at high temperature and high pressure

A high-temperature and high-pressure, graphene technology is applied in the field of high-temperature and high-pressure preparation of graphene materials, and high-temperature and high-pressure sintering to prepare graphene materials with different thicknesses and special shapes, which can solve the problems of no graphene materials and achieve good repeatability and suitable for The effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

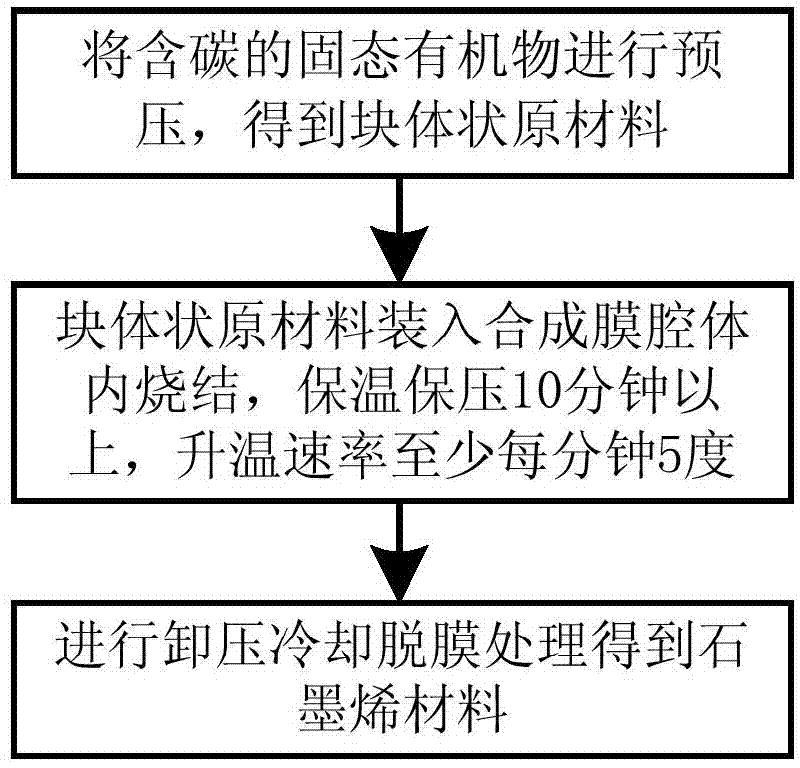

[0021] See attached figure 1 , the method for preparing graphene material at high temperature and high pressure of the present invention may further comprise the steps:

[0022] Step 1: Pre-press the powdered adamantane to obtain bulk adamantane;

[0023] Step 2: Put the block-like adamantane obtained in Step 1 into the cavity of the synthesis module, then put it into high-temperature and high-pressure equipment, and then sinter it. The pressure value is 500MPa and the temperature is 1050°C. 30 minutes, the heating rate is 5 degrees per minute;

[0024] Step 3: The bulk adamantane sintered in step 2 is subjected to pressure relief cooling and demoulding treatment to obtain spherical graphene materials, wherein the pressure relief cooling is carried out slowly.

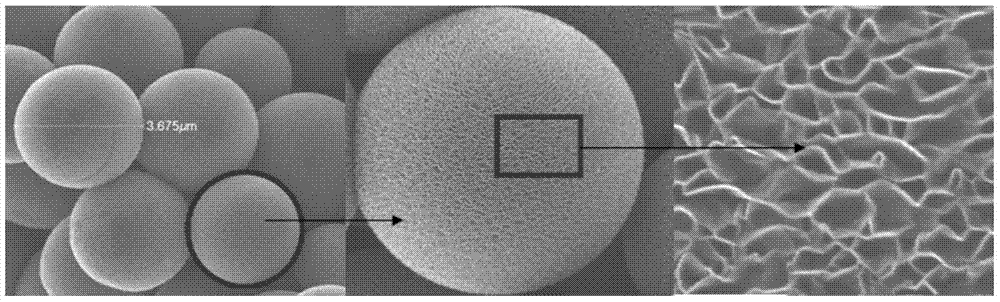

[0025] See attached figure 2 , Carry out Raman spectrum measurement to the spherical graphene material prepared above, the result shows that the samples are all graphene. Among them, peak D appears at 1270-1273cm ...

Embodiment 2

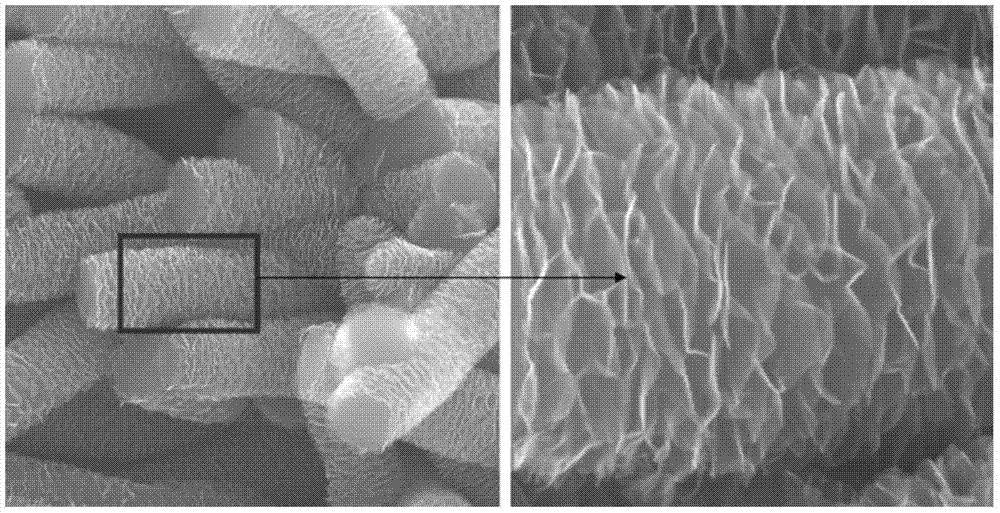

[0027] See attached image 3 , The difference between this embodiment and Embodiment 1 is that under the conditions of pressure 500 MPa and temperature 1050° C., the heating rate is 25 degrees per minute, and the heat preservation and pressure sintering is 30 minutes.

[0028] Raman spectrum measurement was performed on the rod-shaped graphene material obtained by the above sintering, and the results showed that the samples were all graphene. Among them, peak D appears at 1270-1273cm -1 , G peak appears at 1580-1581cm -1 , the 2D peak appears at 2700cm -1 nearby. Compared with the G peak, the D peak is only about 1 / 3 of the G peak, indicating that graphene has fewer defects. Meanwhile, the 2D peak is more than 2 times that of the G peak. A scanning electron microscope (SEM) of the sample revealed that the rod-like material is composed of graphene. The diameter of the rod-shaped graphene is between 0.3-2um, the length is between 0.4-15um, the diameter of the surface pores...

Embodiment 3

[0030] See attached Figure 4 The difference between the present embodiment and the first embodiment is that adamantane is used as raw material, under the conditions of pressure 500MPa and temperature 1050°C, the heating rate is above 60°C per minute, and the heat preservation and pressure sintering is carried out for 30 minutes.

[0031] Carry out Raman spectrum measurement to the above-mentioned prepared flake graphene material, the result shows that the samples are all graphene. Among them, peak D appears at 1270-1273cm -1 , G peak appears at 1580-1581cm -1 , the 2D peak appears at 2700cm -1 nearby. Compared with the G peak, the D peak is only about 1 / 3 of the G peak, indicating that graphene has fewer defects. Meanwhile, the 2D peak is more than 2 times that of the G peak. A scanning electron microscope (SEM) of the sample revealed that the sheet-like material is composed of graphene. The area of sheet-like graphene is 0.3-10um, that is, between single-layer, two-l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com