Trans-polyisoprene (TPI) rubber-cis-polyisoprene rubber composition and processing technique thereof

A technology of polyisoprene and rubber composition, which is applied in the fields of rubber, rubber processing or tire manufacturing, which can solve the problems of reducing the interaction between fillers and polymers, and achieve improved wear resistance, high wear resistance and low heat generation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Formula: SMR2080; synthetic trans polyisoprene TPI20; N115 carbon black 40; silica 10; silane coupling agent X50S3; zinc oxide 3.5; stearic acid 2; antioxidant RD1.5; Wax 1; accelerator CZ1.7; sulfur powder 0.8; anti-scorch agent CTP0.1.

[0065] Embodiment 1 mixing process:

[0066] One stage rubber mixing process:

[0067] Carbon black masterbatch process: add 80 parts by mass of SMR20 to the F370 internal mixer with a rotating speed of 45 rpm for 60 seconds, lift up the top bolt, add 40 parts by mass of carbon black N115, lift up the top bolt for cleaning after 60 seconds of mixing , and then knead for 60 seconds to remove the glue; the pressurized mixing time is 180 seconds, and the glue removal temperature is 165°C;

[0068] White carbon black masterbatch process: Add 20 parts by mass of synthetic trans-isoprene TPI to the F370 internal mixer with a rotating speed of 45 rpm, lift the top bolt after mixing for 60 seconds, add 10 parts by mass of white carbon black...

Embodiment 2

[0082] Formula: SMR2060; IR25; TPI15; N234 carbon black 30; silica 20; silane coupling agent X50S5; zinc oxide 3.5; stearic acid 2; .7; sulfur 1.2.

[0083] Embodiment 2 mixing process:

[0084] One stage rubber mixing process:

[0085] Carbon black masterbatch process: add 60 parts by mass of SMR20 to the F370 internal mixer with a rotating speed of 45 rpm for 60 seconds, lift up the top bolt, add 30 parts by mass of carbon black N234, and lift up the top bolt for cleaning after 60 seconds of mixing , and then knead for 60 seconds to remove glue; the pressurized mixing time is 180 seconds, and the glue removal temperature is 160°C;

[0086] White carbon black masterbatch process: Add 15 parts by mass of synthetic trans-isoprene TPI and 25 parts of synthetic cis-polyisoprene IR into the F370 internal mixer with a rotating speed of 45 rpm, and lift it to the top after mixing for 60 seconds Add 20 parts by mass of white carbon black and 5 parts by mass of silane coupling agen...

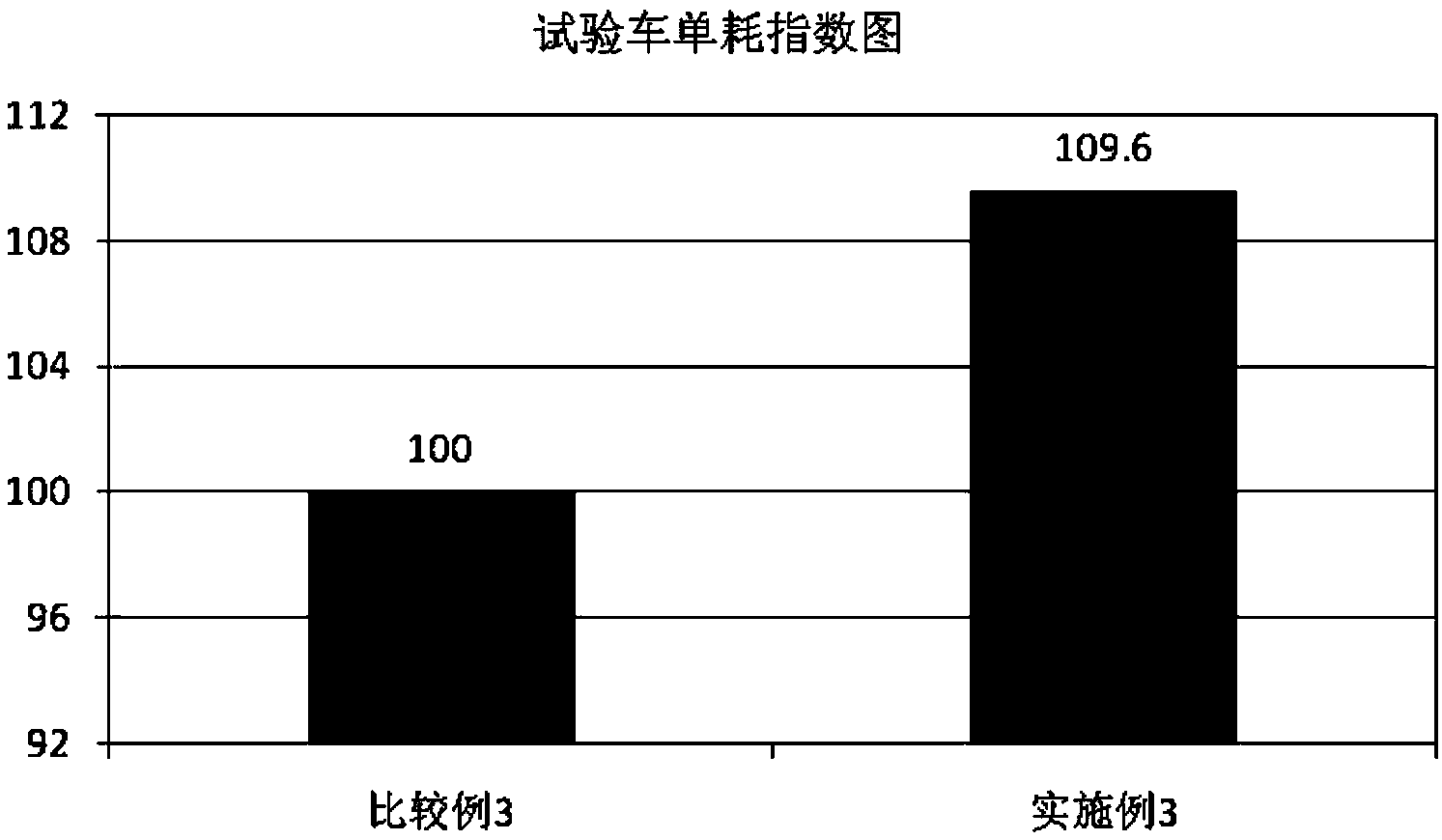

Embodiment 3

[0102] Formula: SMR2070; IR15; TPI15N234 carbon black 35; silica 15; silane coupling agent X50S4; zinc oxide 3.5; stearic acid 2;; antioxidant RD1.5; antioxidant 40202; microcrystalline wax; accelerator CZ1. 8; sulfur 1.2.

[0103] One stage mixing process:

[0104] Carbon black masterbatch process: add 70 parts by mass of SMR20 to the F370 internal mixer with a rotating speed of 45 rpm for 60 seconds, lift up the top bolt, add 35 parts by mass of carbon black N234, lift up the top bolt for cleaning after 60 seconds of mixing , and then kneaded for 60 seconds to remove the glue; the pressurized mixing time was 180 seconds, and the glue removal temperature was 160°C.

[0105] White carbon black masterbatch process: Add 15 parts by mass of synthetic trans-isoprene TPI and 15 parts by mass of synthetic cis-isoprene IR into the F370 internal mixer with a rotating speed of 45 rpm, and lift it to the top after mixing for 60 seconds Add 15 parts by mass of white carbon black and 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com