Novel core material for inorganic-organic composite heat preservation board

A composite thermal insulation and organic technology, applied in the field of building thermal insulation materials, can solve problems such as poor flame retardancy, high cost, and toxic gas hazards, and achieve the effects of improving mechanical properties, improving fluidity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

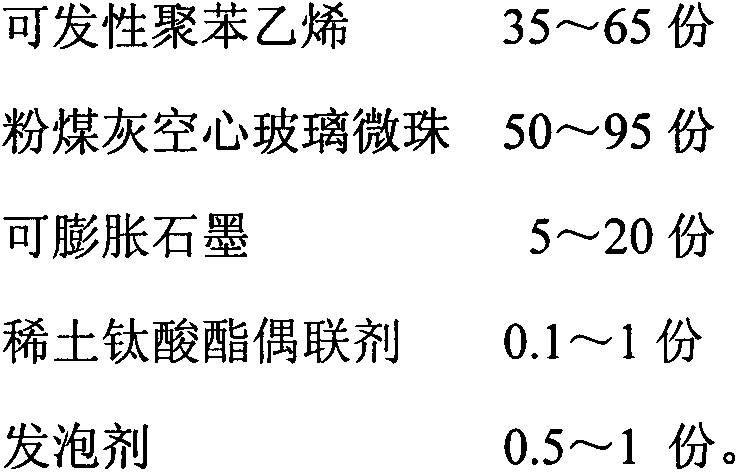

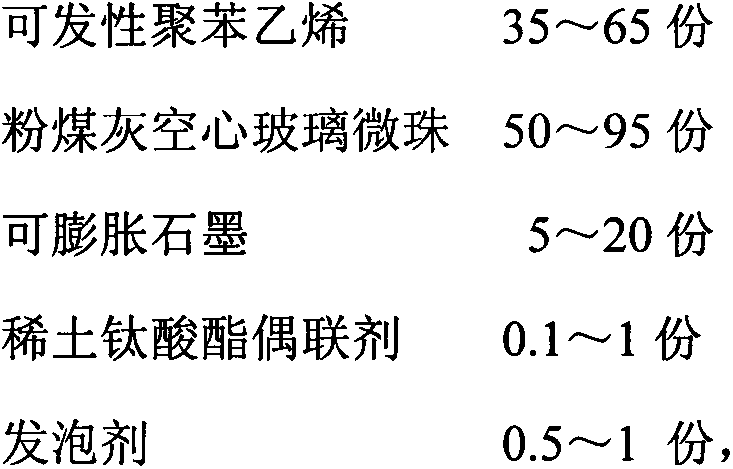

Method used

Image

Examples

Embodiment 1

[0021] First, 500g of fly ash hollow glass microspheres were surface-modified with 5g of rare earth titanate coupling agent, and then extruded with 500g of expandable polystyrene and 150g of expandable graphite using a twin-screw extruder. Granules to make master batches, and finally take the master batches as raw materials, add foaming agent, and extrude at 180-200 °C with an extruder to obtain core materials.

[0022] In order to verify the performance of a novel core material for an inorganic-organic composite insulation board provided by the present invention, the experimental results of Example 1 show that the core material has an oxygen index of 42%, a thermal conductivity of 0.031W / m K, and a compressive strength of 160kPa . The foamed concrete is used as the outer thermal insulation layer and combined with the core material, an inorganic-organic composite thermal insulation board whose combustion performance reaches A2 level can be prepared.

Embodiment 2

[0024] First, 800g of fly ash hollow glass microspheres were surface-modified with 8g of rare earth titanate coupling agent, and then extruded with 400g of expandable polystyrene and 50g of expandable graphite using a twin-screw extruder. Granules to make master batches, and finally take the master batches as raw materials, add foaming agent, and extrude at 180-200 °C with an extruder to obtain core materials.

Embodiment 3

[0026] First, 700g of fly ash hollow glass microspheres were surface-modified with 7g of rare earth titanate coupling agent, and then extruded with 650g of expandable polystyrene and 200g of expandable graphite using a twin-screw extruder. Granules to make master batches, and finally take the master batches as raw materials, add foaming agent, and extrude at 180-200 °C with an extruder to obtain core materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com