Medium-frequency quenching process of smoothing roll and quenching equipment thereof

The technology of quenching equipment and straightening roll is applied in the field of intermediate frequency quenching process of straightening roll and quenching equipment, which can solve the problems of high power requirement, complex inductor fabrication and high cost, and achieve the effect of requiring small power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

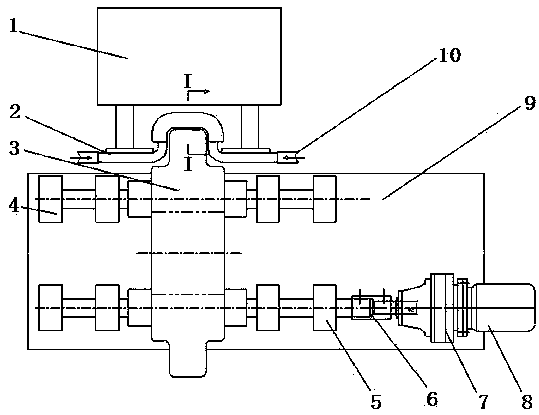

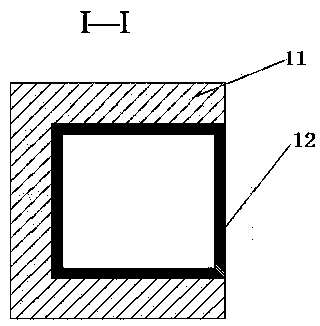

[0019] The invention adopts a three-phase frequency conversion speed regulator to control the motor speed, the motor directly drives the reducer to rotate, the output shaft of the reducer drives the driving roller to rotate through the coupling, and the driving roller drives the straightening roller to rotate through friction. An intermediate frequency quenching inductor is fixedly placed on the quenching surface. When the intermediate frequency quenching inductor inputs intermediate frequency current, the surface of the straightening roller close to the inductor will be subjected to electromagnetic induction. The surface of the straightening roller is heated, and when the surface of the straightening roller is heated to the austenitizing temperature, it is transferred to the water spray cooling area for quenching treatment to complete the local quenching process. By controlling the continuous rotation of the straightening roller, the surface of the straightening roller through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com