Ship scr system

A technology of SCR system and marine engine, which is applied in the field of SCR system, can solve the problems of reduced conversion efficiency, uneven distribution, increased ammonia leakage, etc., and achieve the effect of increasing the contact area and uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

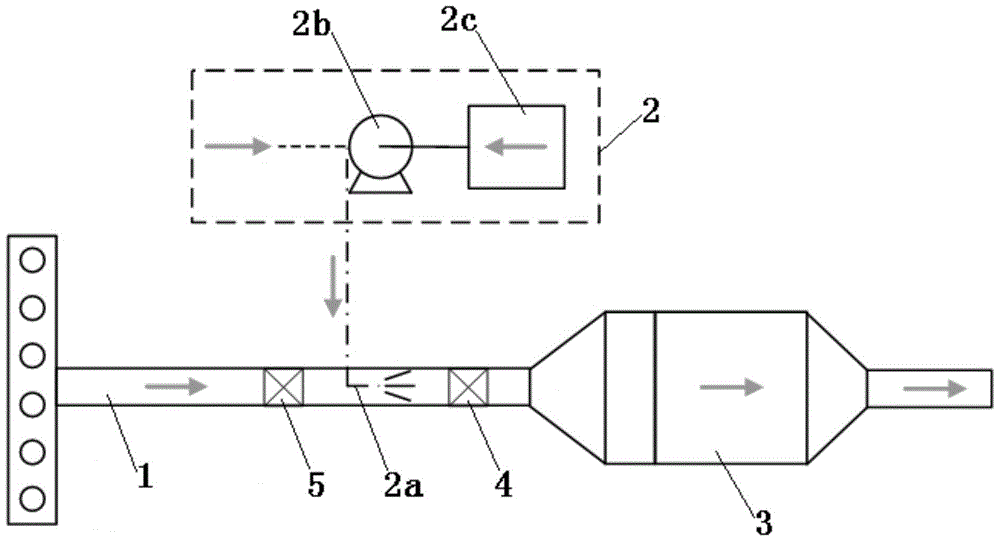

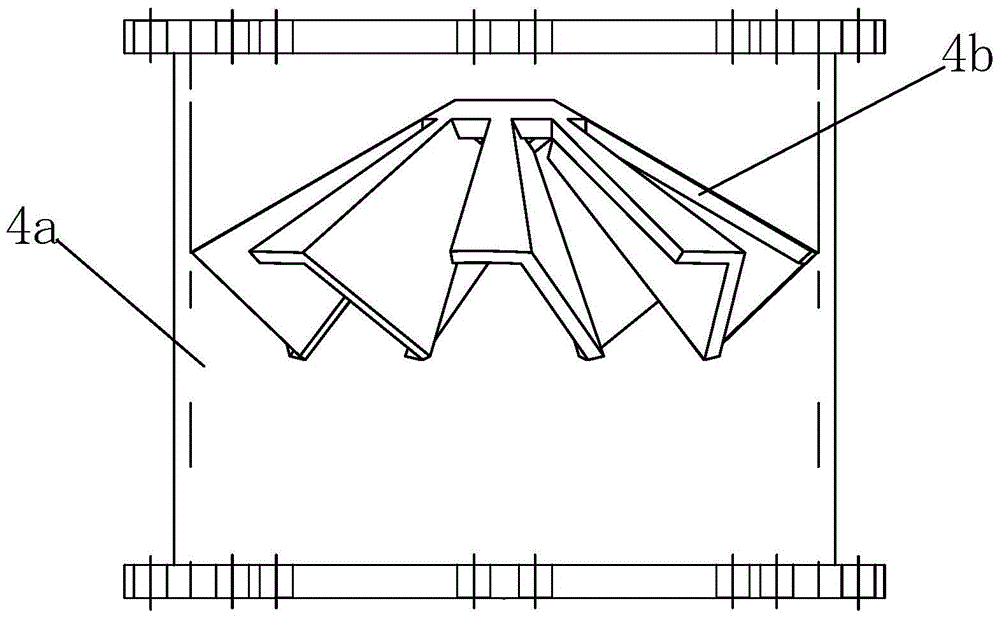

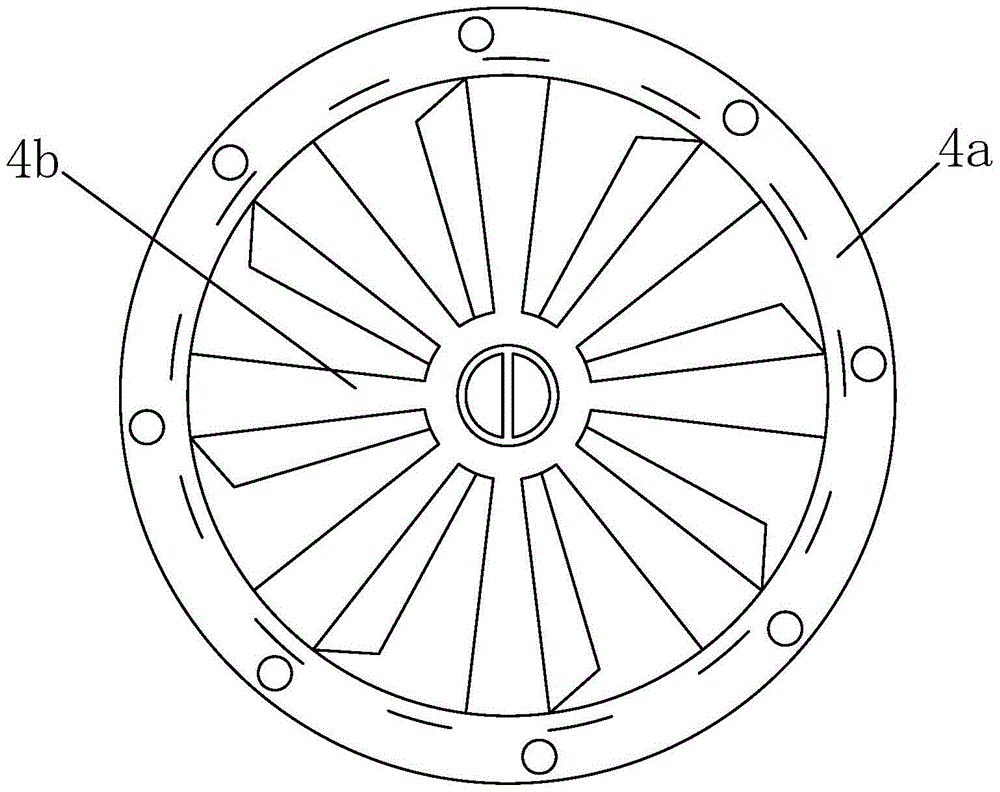

[0046] Such as figure 1 A marine engine SCR system shown includes an engine exhaust pipe 1, a blue injection system 2 and a catalytic converter 3, the exhaust port of the engine exhaust pipe 1 communicates with the intake port of the catalytic converter 3, The nozzle 2a of the Tianlan injection system 2 is arranged in the engine exhaust pipe 1, and a mixer 4 is arranged between the engine exhaust pipe 1 and the catalytic converter 3, and the mixer 4 includes a cylindrical Structure of the mixer tube body 4a and the vane assembly 4b fixedly installed in the mixer tube body 4a;

[0047] The blade assembly 4b includes a central circular boss 4b1 and blade assemblies 4b2 uniformly arranged along the circumferential direction of the outer edge of the central circular boss 4b1;

[0048] The blade assembly 4b2 further includes a straight blade 4b2a a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com