Circulating fluidized bed waste sludge incinerator

A circulating fluidized bed and sludge incineration technology, which is applied to incinerators, combustion methods, combustion types, etc., can solve the problems of large system resistance, ash blocking of heat exchange equipment, and high moisture content of raw materials, and improve the safe operation rate. , The effect of reducing the system resistance and improving the combustion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

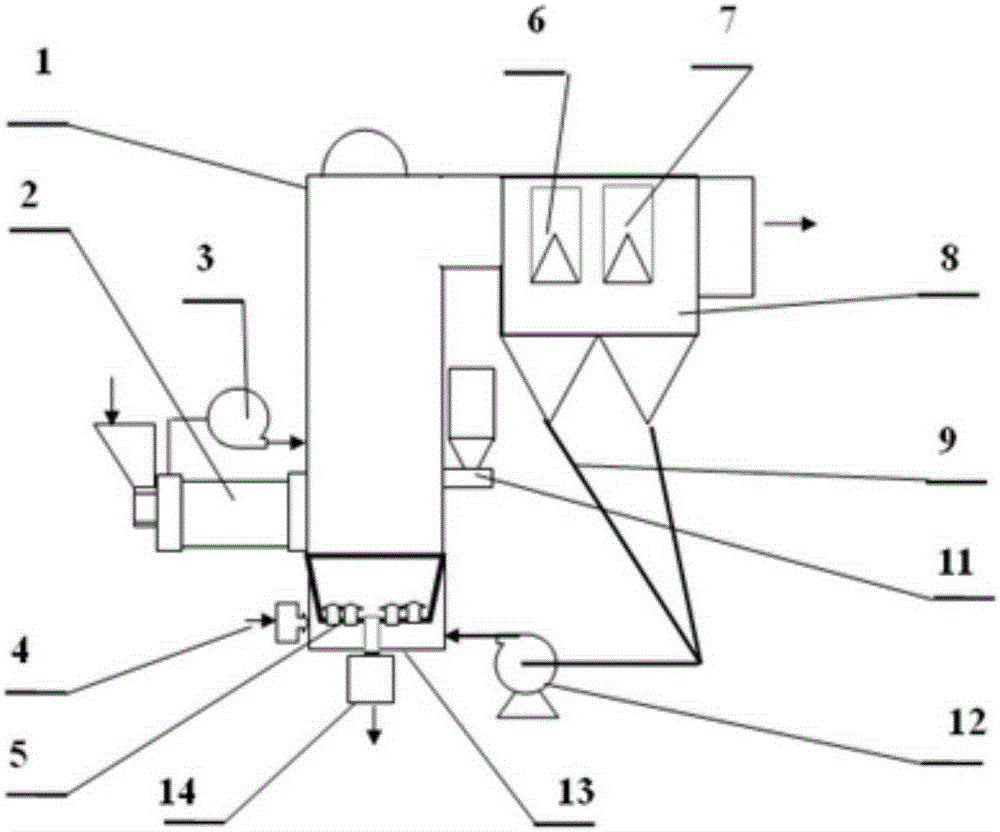

[0013] Example. Circulating fluidized bed waste sludge incinerator, such as figure 1 As shown, the fluidized bed boiler 1 is provided with a countercurrent drying pyrolysis feeder 2, the bottom of the fluidized bed boiler 1 is provided with a high temperature wind box 13, and the lower part of the high temperature wind box 13 is provided with a cooling slagging device 14, and the fluidized bed boiler 1 The top is connected with a thermal insulation air preheater 8; the inlet of the high temperature air box 13 is connected to the primary fan 12; the suction port of the primary fan 12 is connected to the thermal insulation air preheater 8; the thermal insulation air preheater 8 is provided with coil superheater 6 and coil economizer 7. The fluidized bed boiler 1 is also provided with an auxiliary fuel supply device 11 . The hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com