Bituminous mixture heat conduction testing device

An asphalt mixture and testing device technology, applied in the direction of material thermal development, material thermal conductivity, etc., can solve the problems of small size of the test piece, difficult to guarantee the test and test accuracy, etc., to achieve easy operation, improve test accuracy, and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the protection scope of the present invention.

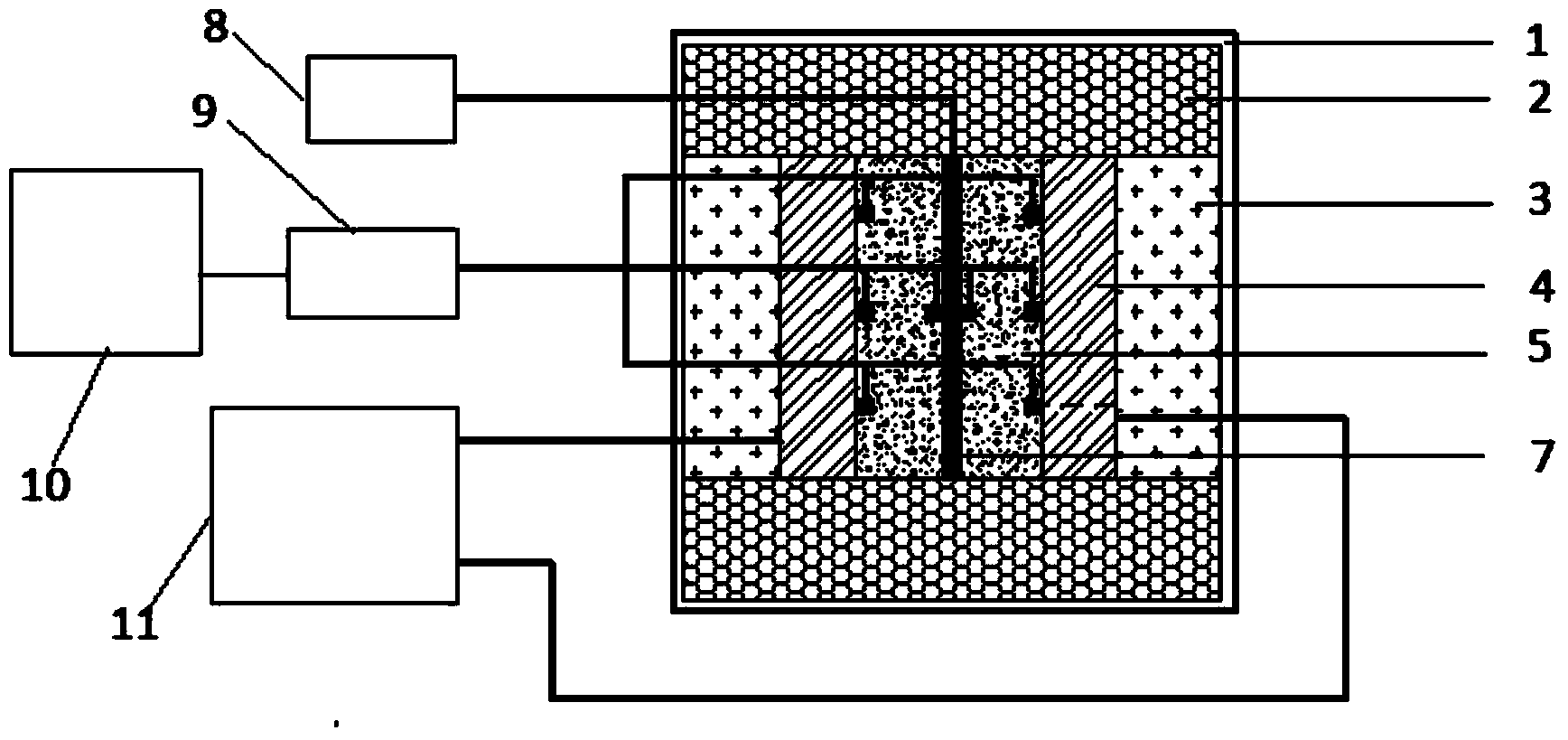

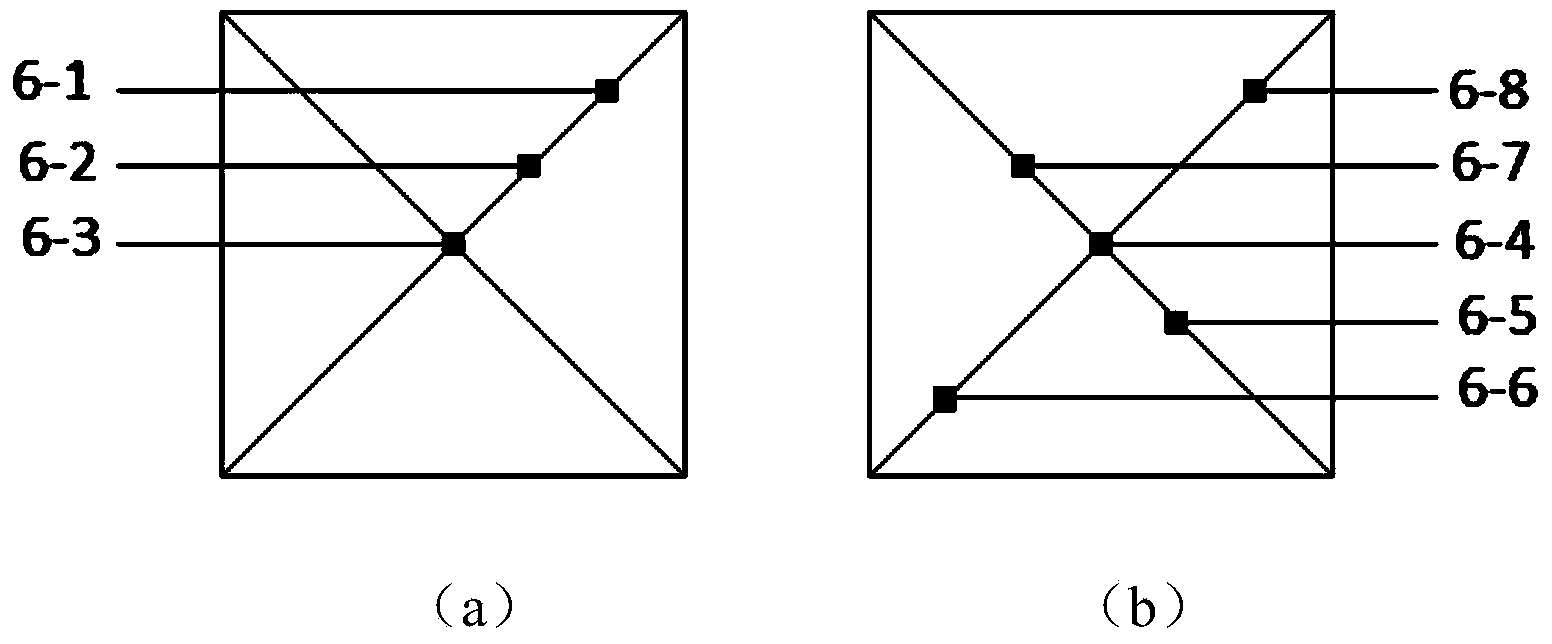

[0022] Such as figure 1 As shown, a kind of asphalt mixture heat conduction test device provided by the present invention includes a test chamber 1, a polyurethane foam insulation layer 2, an asbestos insulation layer 3, a constant temperature circulating water tank 4, a heating plate 7, a temperature controller 8, and temperature data collection Instrument 9, computer 10, intelligent constant temperature circulator 11, wherein, heat insulating material is laid on the inner wall of test chamber 1 to form polyurethane foam heat insulation layer 2, and asbestos heat insulation layer 3 is laid on polyurethane foam heat insulation layer 2; A circulating water tank 4, and a heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com