Edge ring of etching device

A technology of etching equipment and edge ring, applied in the field of edge ring, can solve problems such as cavity pollution, weak adhesion, polymer peeling, etc., and achieve the effect of cleaning cycle guarantee, guaranteed yield, and reduced obstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this embodiment, an edge ring in the prior art is introduced first.

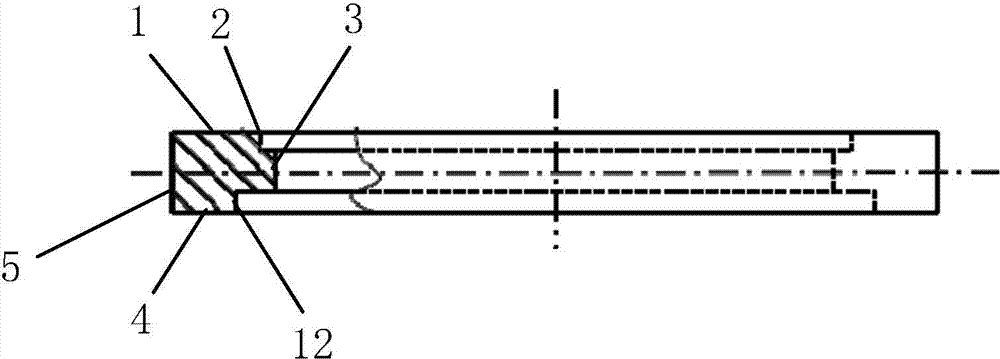

[0027] see figure 1 , figure 1It is a structural cross-sectional view of an edge ring in the prior art, and an example of an edge ring disclosed by a Lam Research Corporation (Lam Research Co., Ltd.) model is a machine of LAM AL-PAD Metal. As shown in the figure, the edge ring is horizontally arranged above the cathode in the cavity of the etching equipment during use, and shields and protects the cathode from plasma bombardment; the edge ring has upper and lower surfaces 1, 4 and vertical etc. High side 5, the edge ring is provided with a central through hole 3 surrounding the substrate, the through hole 3 is located on the upper surface of the edge ring 1, and the orifice is provided with a concentric upper step hole 2 for converging radio frequency energy, and the through hole 3 is located on the lower surface of the edge ring 4 The orifice is provided with a concentric lower stepped hole 12 f...

Embodiment 2

[0034] In this example, see Figure 4 , Figure 4 It is a cross-sectional view of another partial structure of an edge ring of an etching device in the present invention with a slope on its upper surface. As shown in the figure, the upper surface of the edge ring of the present invention has a slope 10 that slopes downward in the direction of the side surface 5 . The starting point of the inclined plane 10 is located at the horizontal center position between the upper stepped hole 2 of the edge ring and the side surface 5, and intersects with the side surface 5 of the edge ring. If the length of the bevel is further shortened, the effect of the bevel will not be brought into full play, and the etching products will also accumulate near the plane position of the upper surface of the edge ring before the start of the bevel structure. In this example, the angle between the inclined plane 10 and the horizontal plane is 45 degrees. A larger inclination angle will weaken the driv...

Embodiment 3

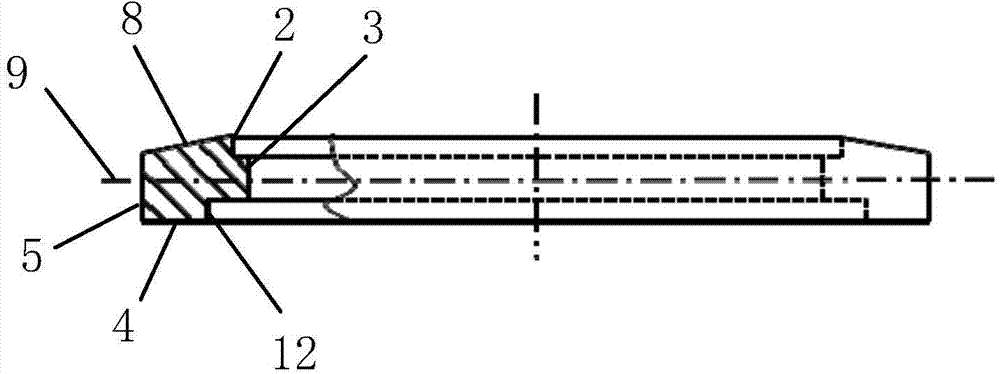

[0036] In this example, see Figure 5 , Figure 5 It is a sectional view of a partial structure of an edge ring of an etching device in the present invention with an arc surface. As shown in the figure, the upper surface of the edge ring of the present invention has a downwardly inclined arc surface 11 towards the side surface 5 . In this example, the arc surface 11 is processed into a parabolic shape. The arc surface 11 starts at the opening of the upper stepped hole 2 of the edge ring and is tangent to the side surface 5. The highest point of the arc surface 11 on the horizontal plane is located at the upper stepped hole 2. at the orifice. The parabola symmetry axis of the parabola of the arc surface 11 is parallel to the horizontal plane, and the parabola apex of the parabola is located at the point of tangency with the side surface 5 . The point of tangency between the arc surface 11 and the side surface 5 should be located above the horizontal centerline 9 of the edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com