Flexible temperature difference generation micro-unit structure

A thermoelectric power generation, micro-unit technology, applied in electrical components, generators/motors, etc., can solve the problems of thermoelectric power generation unit failure, insufficient stability of thermoelectric generators, easy fracture of alloy materials, etc., and achieve the effect of avoiding failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

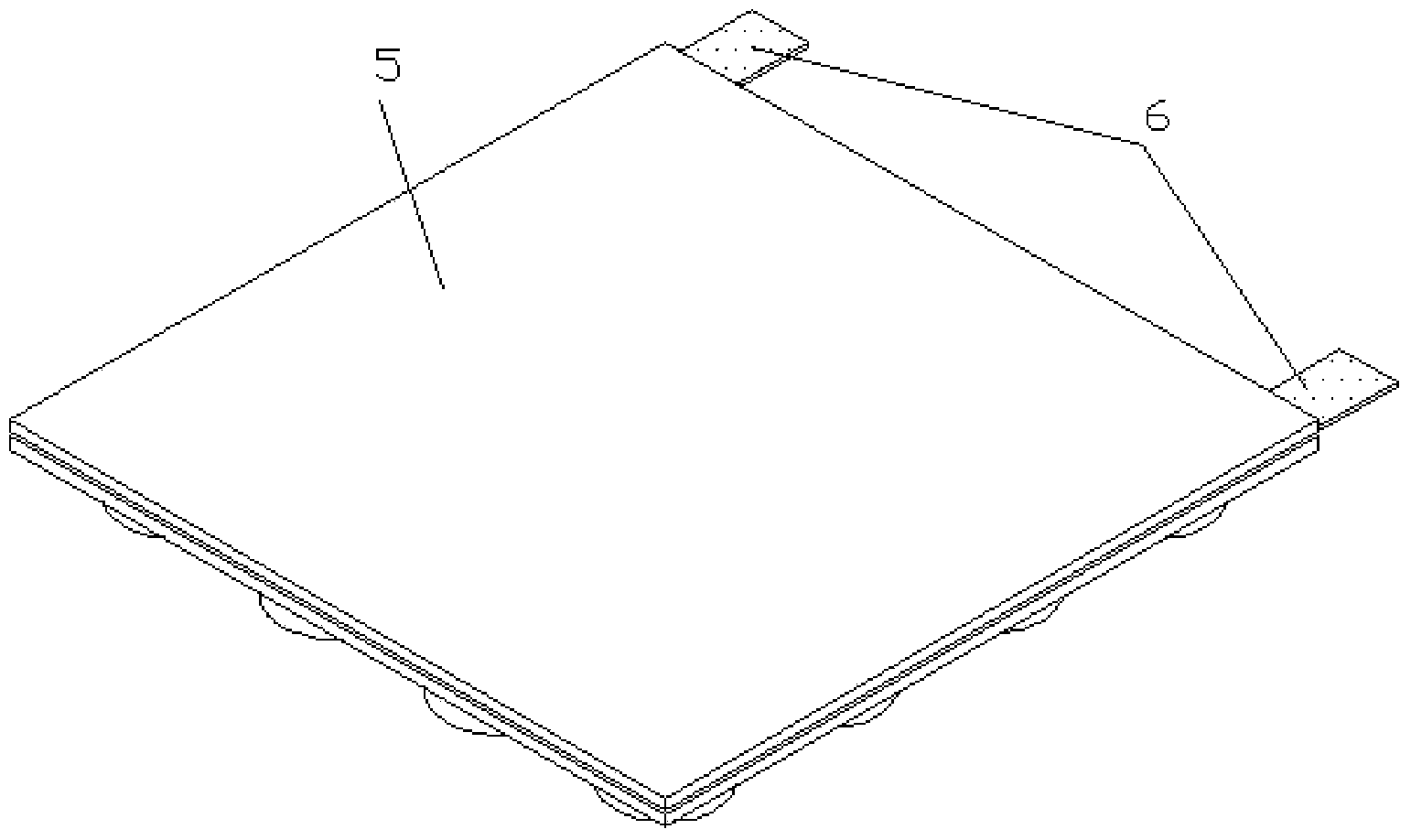

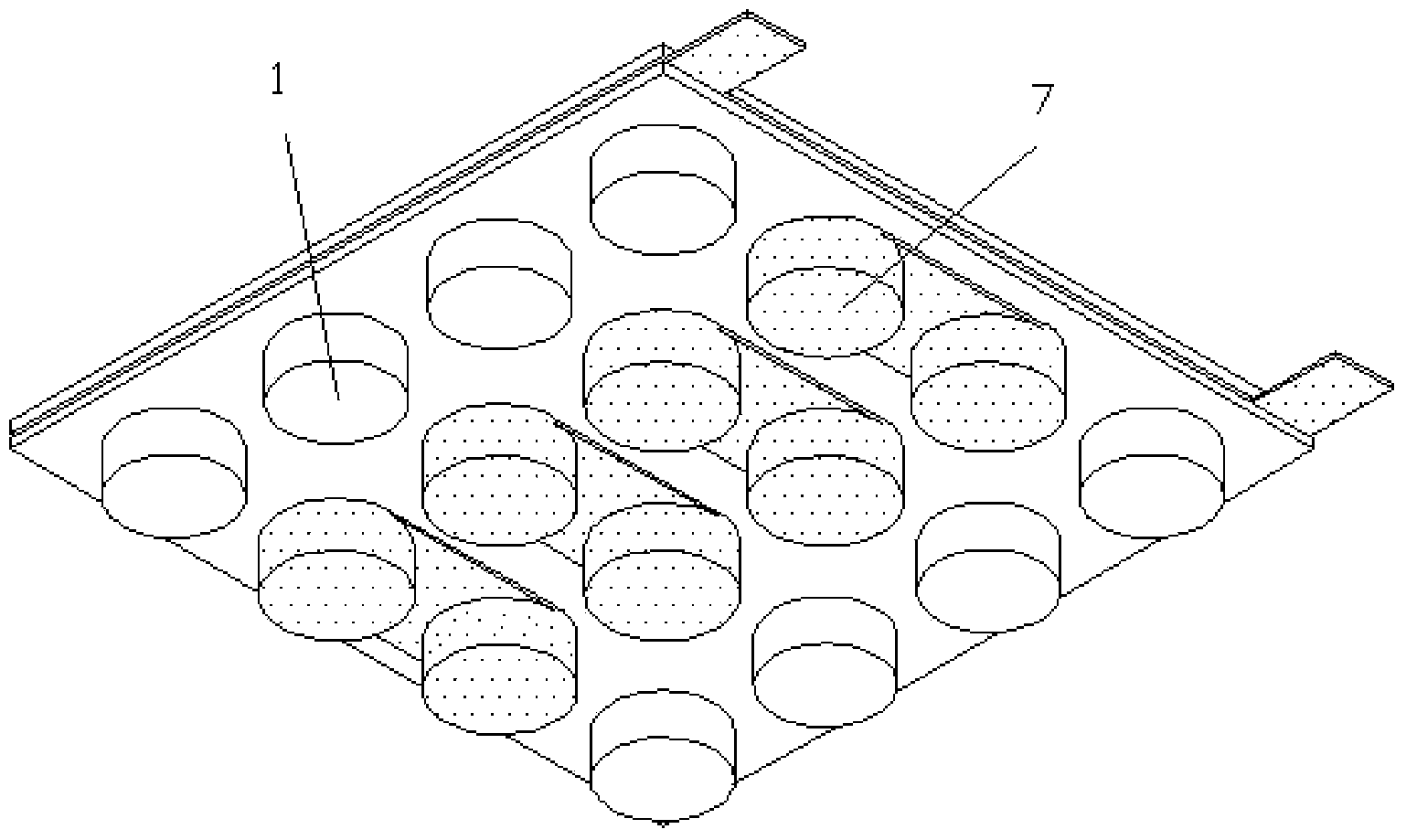

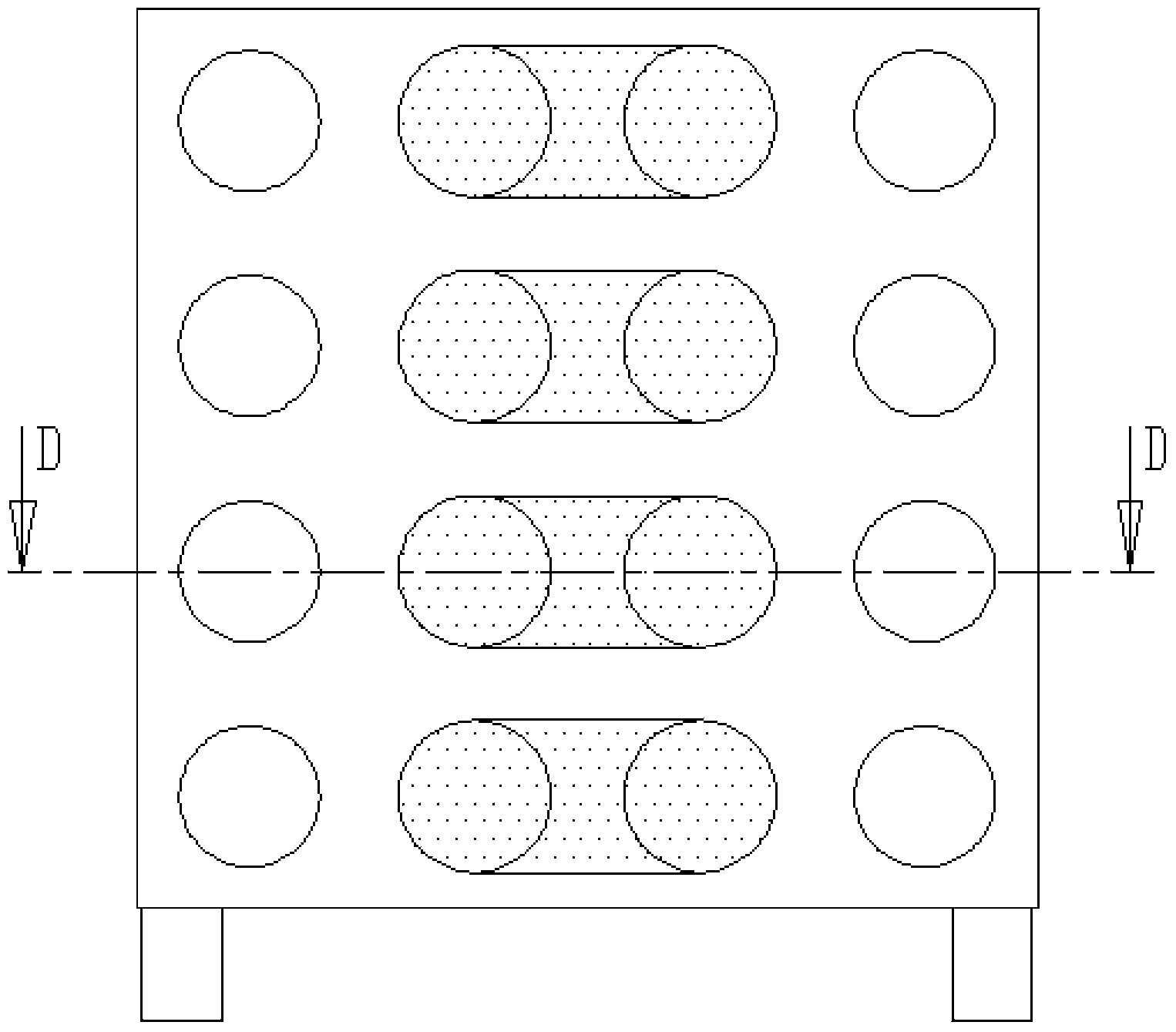

[0025] Such as Figure 9 As shown, the present invention casts polyimide in the lower film 9 of the polyimide base mold, extrudes with the upper mold 8 of the polyimide base mold, and solidifies into the base 1 of the honeycomb circular cavity. Such as figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, the present invention has multiple rows and multiple even columns of honeycomb circular cavities on the substrate 1 (there are four rows and four rows of circular cavities in the figure, as long as figure 2 The number of columns can be increased by arraying the two columns in the middle), except for the two rows of circular cavities on the edge, there is a microhole at the bottom of the other circular cavities, such as Figure 11 As shown, the silver-based nanoparticle ink 2 is drip-coated with silver-based...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com