Control circuit board for electronic mosquito swatter and production process thereof

A technology for controlling circuit boards and production processes, applied in the direction of assembling printed circuits with electrical components, printed circuits, printed circuits connected with non-printed electrical components, etc. It can improve product reliability and shock resistance, reduce electromagnetic and radio frequency interference, and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

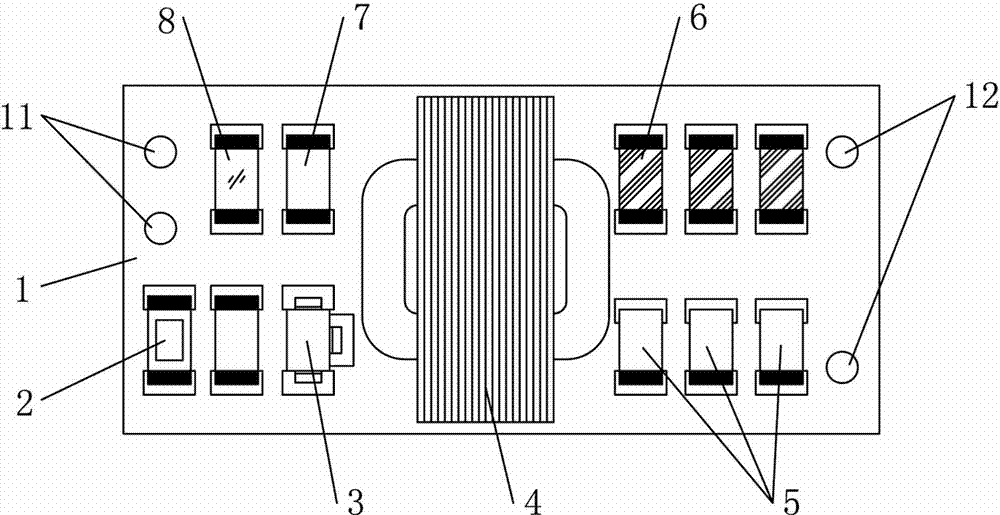

[0036] Embodiment one, see figure 1 As shown, a control circuit board for an electric mosquito swatter, including electronic components and a PCB board 1 provided with circuits, the electronic components and the PCB board 1 are welded and fixed, and the PCB board 1 is provided with a DC input terminal 11 and a high-voltage output terminal 12, The electronic components are composed of mount-type components and plug-in components, and the mount-type components include chip capacitors 6, chip resistors 7, chip transistors 3, chip diodes 5, chip LEDs 8 and chip The plug-in components of the switch 2 include an inductance transformer coil 4 .

[0037] The PCB board 1 is provided with lines on one side.

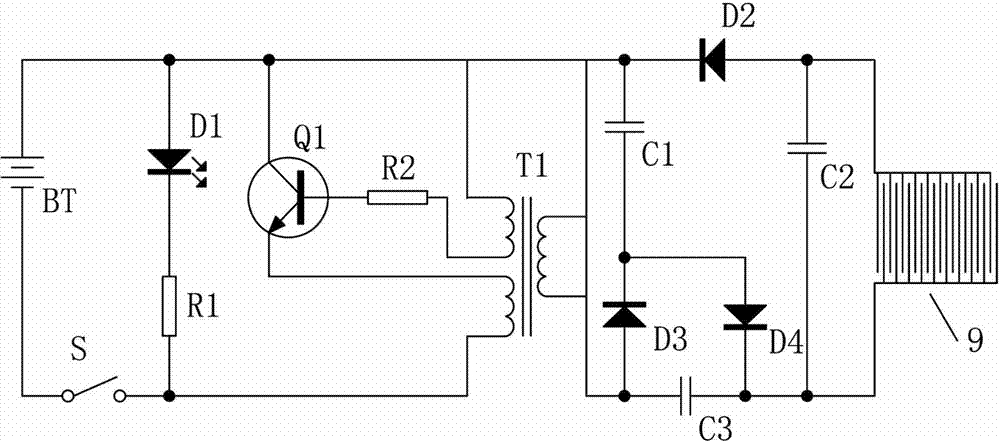

[0038] combine figure 2 , is the circuit diagram of the control circuit board, figure 2 Among them, R1 and R2 are equivalent to chip resistors 7, C1, C2 and C3 are equivalent to chip capacitors 6, Q1 is equivalent to chip transistors 3, D2, D3 and D4 are equivalent to chip dio...

Embodiment 2

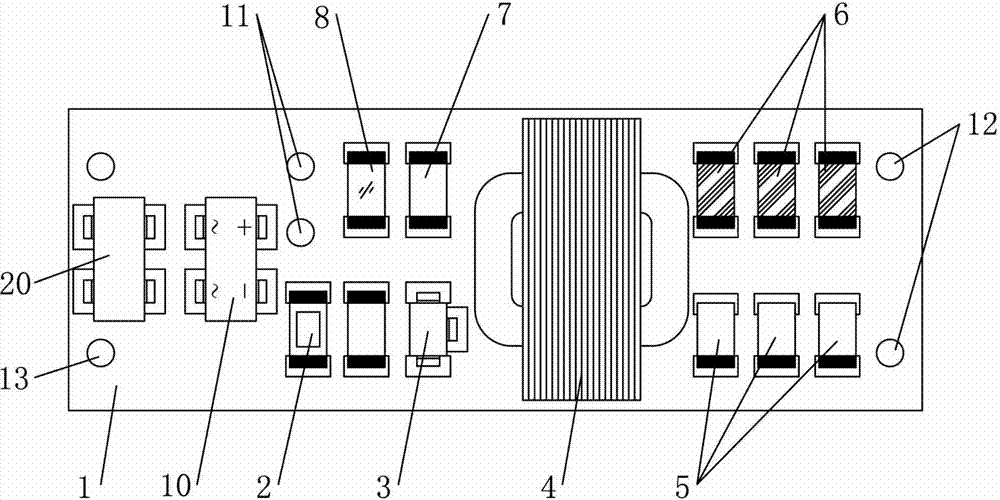

[0039] Embodiment two, the difference with embodiment one is: see image 3 with Figure 4 As shown, the mounted component also includes a step-down chip 20 and an integrated rectifier semiconductor 10 , and the PCB 1 is also provided with a commercial power input terminal 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com