Backwashing method applicable to control of pollution of internal compression type membrane

A backwash, internal pressure technology, applied in the system field, can solve the problems of strong capillary effect and poor control effect of internal pressure membrane fouling, and achieve the effect of prolonging membrane life, controlling membrane fouling phenomenon, and prolonging chemical cleaning cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0020] 1. A backwashing method suitable for controlling internal pressure membrane fouling. The washing steps are as follows:

[0021] 1) After the membrane filtration is completed, the internal pressure membrane is firstly subjected to the flushing step;

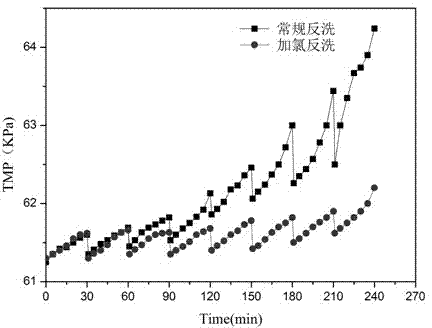

[0022] 2) After the flushing described in step 1) is completed, the backwashing step with chlorinated water is performed on the internal pressure membrane;

[0023] 3) After the chlorinated water backwashing step described in step 2) is completed, the forward flushing step is performed again; after the forward flushing is completed, the cleaning of the internal pressure control membrane is completed.

[0024] In step 2), backwash water containing a certain concentration of available chlorine is used to backwash the membrane. Step 1) After the middle membrane filtration process, the internal pressure membrane is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com