Preparation method and application of sulfur-doped antimony oxide visible light photocatalyst

A technology of photocatalyst and antimony oxide, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of limited application and large band gap, and achieve easy control, simple process, high The effect of high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of nano-powder precursor solution:

[0024] 0.6844g SbCl 3 , 70ml of deionized water, 0.3005g of thioacetamide were stirred and mixed at room temperature, and the pH was adjusted to 12 by 4mol / L NaOH to obtain a nanopowder precursor.

[0025] (2) Preparation of nano powders under hydrothermal conditions:

[0026] Put the above-mentioned nano-powder precursor solution in a high-pressure reactor, heat it up to 120°C at a rate of 5°C / min and keep it warm for 12 hours for hydrothermal reaction. After the reaction is completed, naturally cool to room temperature and take it out. After washing with ethanol for 4 times, put it into a drying oven and dry at 70°C to obtain a sulfur-doped antimony oxide visible light photocatalyst.

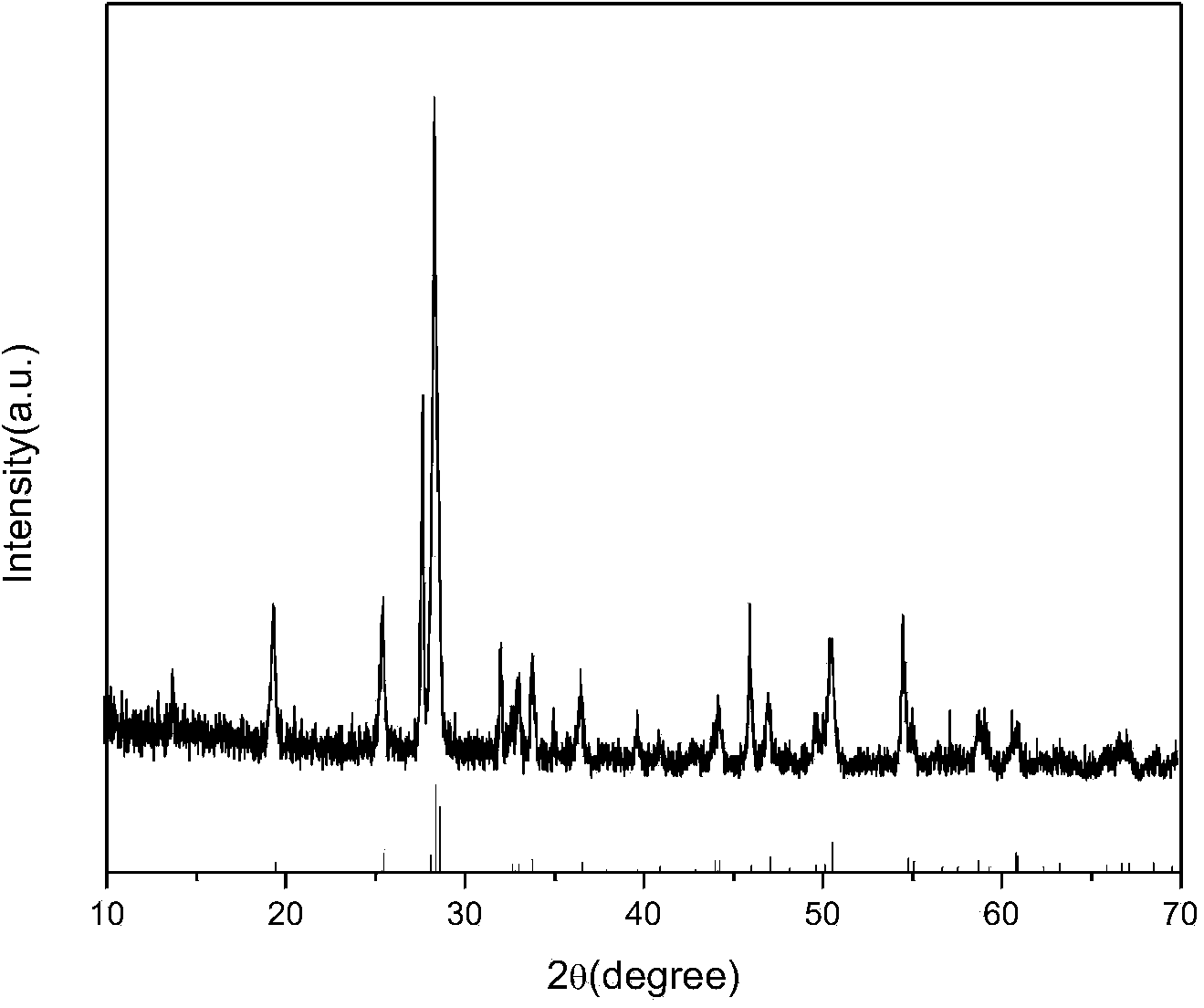

[0027] The S-doped Sb prepared in this embodiment 2 o 3 The X-ray diffraction pattern of figure 1 shown.

[0028] The S-doped Sb prepared in this embodiment 2 o 3 The transmission electron microscope image is shown in Fig.

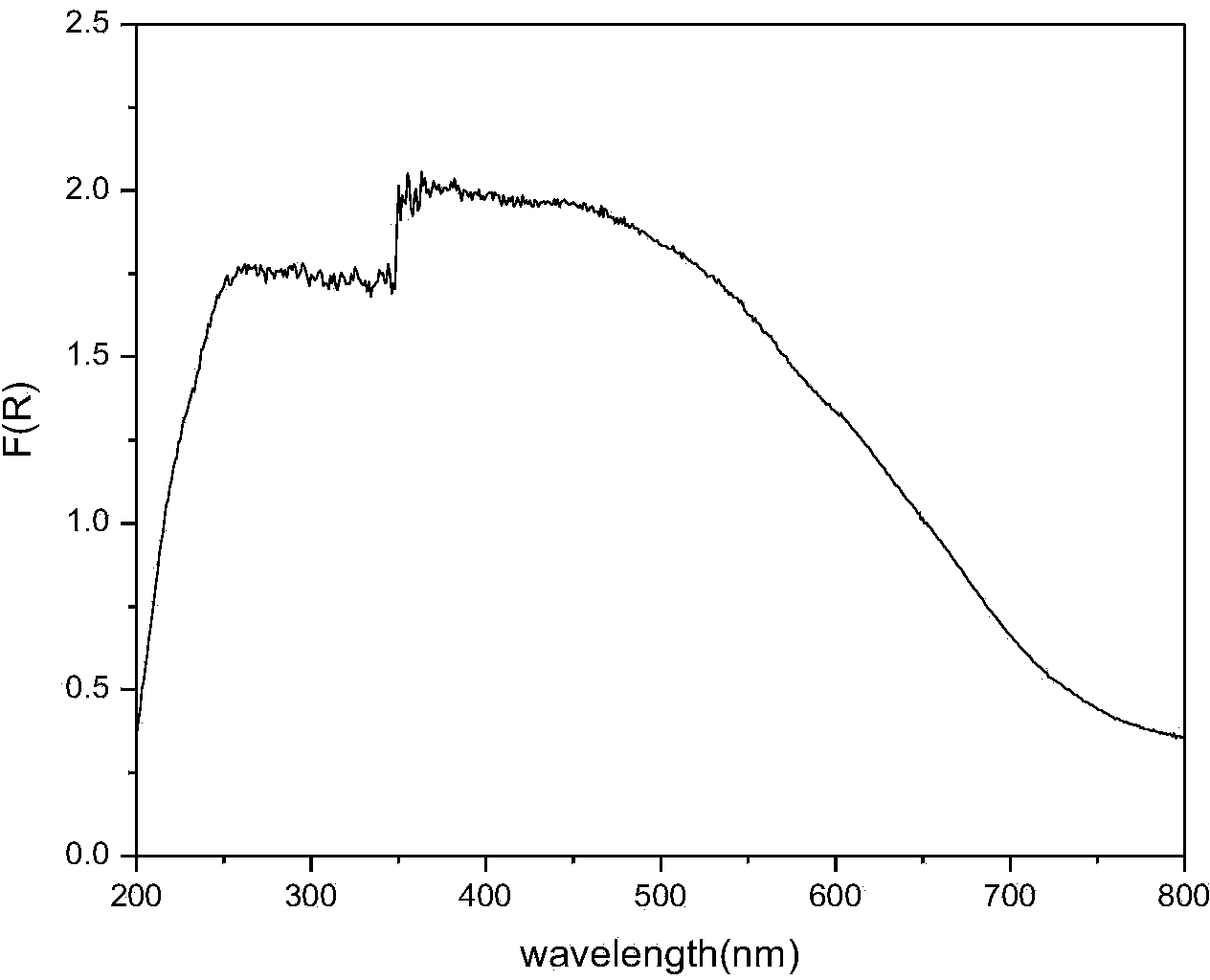

...

Embodiment 2

[0031] (1) Preparation of nano-powder precursor solution:

[0032] 0.6844g SbCl 3 , 70ml of deionized water, and 0.4007g of thioacetamide were stirred and mixed at room temperature, and the pH was adjusted to 12 by 5mol / L NaOH to obtain a nanopowder precursor.

[0033] (2) Preparation of nano powders under hydrothermal conditions:

[0034] Put the above-mentioned nano-powder precursor solution in a high-pressure reactor, heat it up to 140°C at a rate of 2°C / min and keep it warm for 12 hours for hydrothermal reaction. After washing with ethanol for 4 times, put it into a drying oven and dry at 60°C to obtain a sulfur-doped antimony oxide visible light photocatalyst.

Embodiment 3

[0036] (1) Preparation of nano-powder precursor solution:

[0037] 1.0266g SbCl 3 , 65ml of deionized water, and 0.3005g of thioacetamide were stirred and mixed at room temperature, and the pH was adjusted to 13 by 6mol / L NaOH to obtain a nanopowder precursor.

[0038] (2) Preparation of nano powders under hydrothermal conditions:

[0039] Put the above-mentioned nano-powder precursor solution in a high-pressure reactor, heat it up to 160°C at a rate of 3°C / min and keep it warm for 10 hours for hydrothermal reaction. After the reaction is completed, cool it down to room temperature naturally and take it out. After washing with ethanol for 5 times, put it into a drying oven and dry at 65°C to obtain a sulfur-doped antimony oxide visible light photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com