Nano rod and preparation method and application thereof

A nanorod and gold nanorod technology, applied in the field of nanorods and their preparation, can solve the problems of nanoparticle catalytic activity regulation, unreported substrate selectivity, harsh preparation conditions, etc., and achieves low reagent cost and high repeatability. , the effect of the simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of the nanorod provided by the present invention comprises contacting a soluble platinum salt, a soluble copper salt, and a reducing agent with a gold nanorod in the presence of a solvent, and the amount of the soluble platinum salt is 0.1 per mole of gold atoms. -0.5 mol, the amount of the soluble copper salt is 0.01-3 mol, and the amount of the reducing agent is 2-20 mol.

[0023] Wherein, the solvent may be various solvents used in preparing nanorods, for example, water.

[0024] The inventors of the present invention found that if the amounts of soluble platinum salt, soluble copper salt, reducing agent and gold nanorods are not within the above-mentioned range defined in the present invention, it is difficult to obtain nanorods with high catalytic activity and CuPt alloy nano-island structure.

[0025] In the present invention, the conditions of the contact are not particularly limited. Preferably, the conditions of the contact include a temp...

Embodiment 1-9

[0055] This example is used to illustrate the preparation method of the nanorods of the present invention.

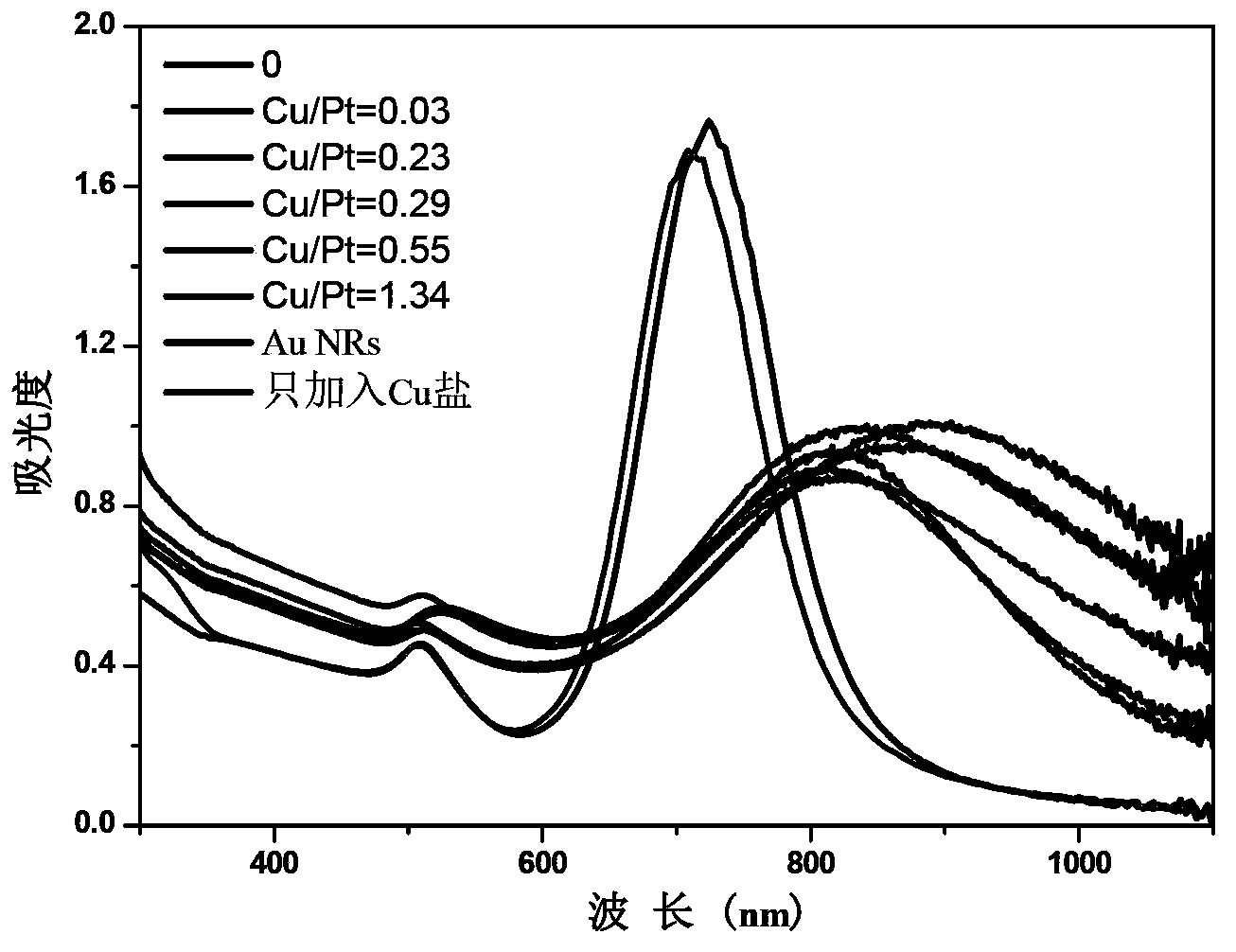

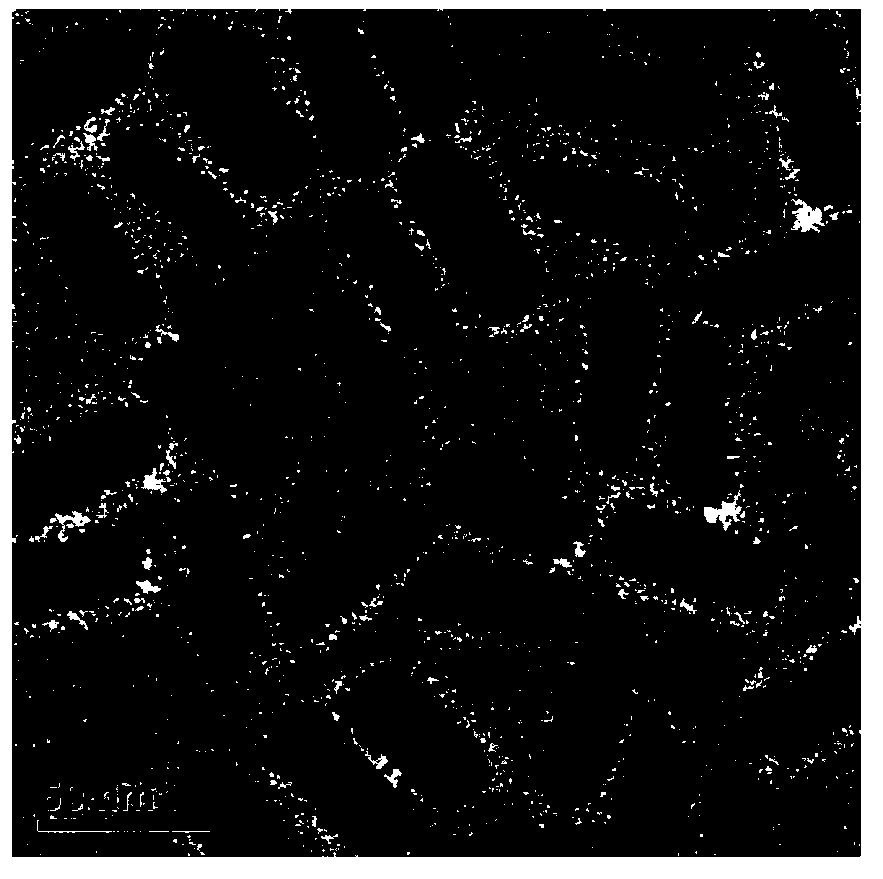

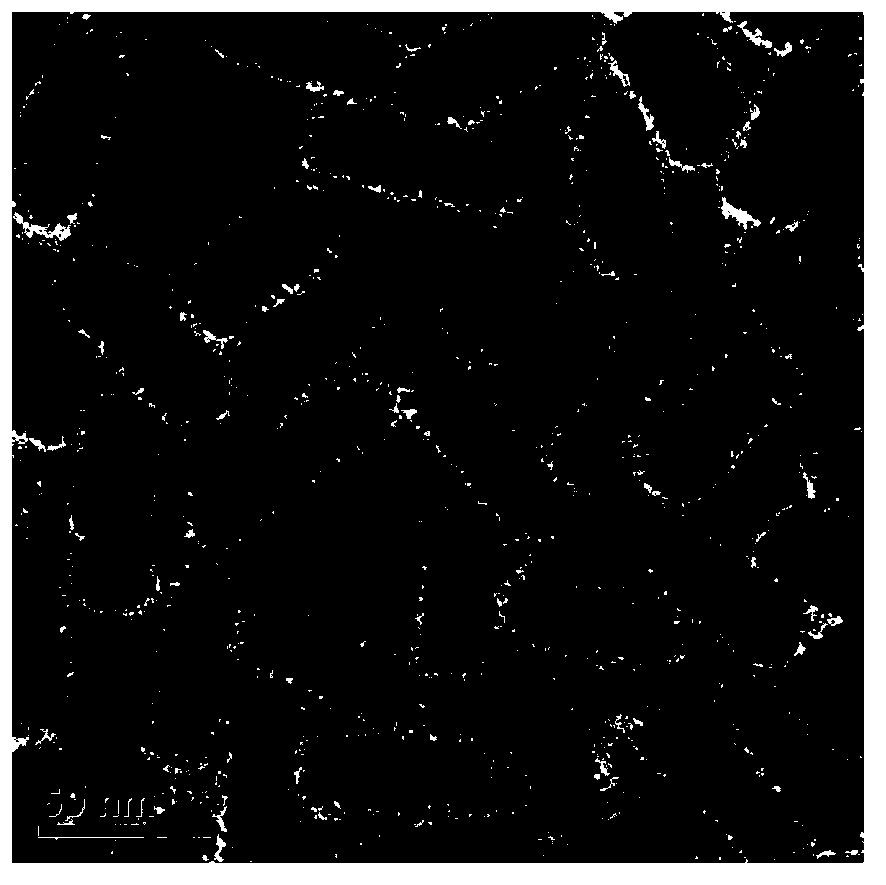

[0056] Take 1 mL of purified gold nanorod solution, add 5 μL of 10 mM CTAB aqueous solution and dilute to 2 mL with deionized water, add 10 mM copper chloride aqueous solution, 2 mM K 2 PtCl 4 Aqueous solution, after mixing evenly, add 0.1M AA solution, shake well and put it in a constant temperature water bath. After a period of time, a solution of nanorods with CuPt alloy nano-island structure is obtained, and then add 0.5mL CTAB solution with a concentration of 0.1M, Measure ultraviolet-visible-near-infrared absorption spectrum, the measurement result of embodiment 1,3,4,5,7 is respectively as figure 1 In Cu / Pt=0.03 line, Cu / Pt=0.23 line, Cu / Pt=0.29 line, Cu / Pt=0.55 line, Cu / Pt=1.34 line. Then centrifuge at 12000rpm for 5 minutes twice, redisperse the precipitate in 100 μL deionized water to obtain a sample, take 6 μL of the sample and drop it on a copper grid, and...

Embodiment 10

[0066] Take 1 mL of the purified gold nanorod solution, dilute it to 2 mL with deionized water, and add 23.5 μL of 2 mM K 2 PtCl 4 After the aqueous solution was mixed evenly, 8 μL of ascorbic acid solution with a concentration of 0.1 M was added, shaken well, and placed in a constant temperature water bath at 30° C. to react for 3 hours to obtain a seed solution of AuPt0.1. Then, 5 μL of 10 mM CTAB aqueous solution, 40 μL of 10 mM copper chloride aqueous solution, 75 μL of 2 mM K 2 PtCl 4 Aqueous solution, after mixing evenly, add 22.5 μL of ascorbic acid solution with a concentration of 0.1M, shake well and put it in a constant temperature water bath at 30°C for 30 minutes to react. After 30 minutes, a solution of nanorods with a CuPt alloy nano-island structure was obtained, to which 0.5ml of CTAB solution with a concentration of 0.1M was added, centrifuged at 12000rpm for 5 minutes twice, and the precipitate was redispersed in 100 μL of deionized water, and 6 μL of samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com