Connection method of dissimilar metal rings and metal pipe fitting assembly joints

A technology of metal pipe fittings and dissimilar metals, which is applied in the field of solid connection of dissimilar metals, can solve the problems of not being able to obtain high-quality impact joints with wave interfaces and jets, not being able to obtain metallurgical joints, and difficult to meet high sealing and high strength, etc., to achieve Improved relative positional relationship, high strength, optimized impact speed and angle matching effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

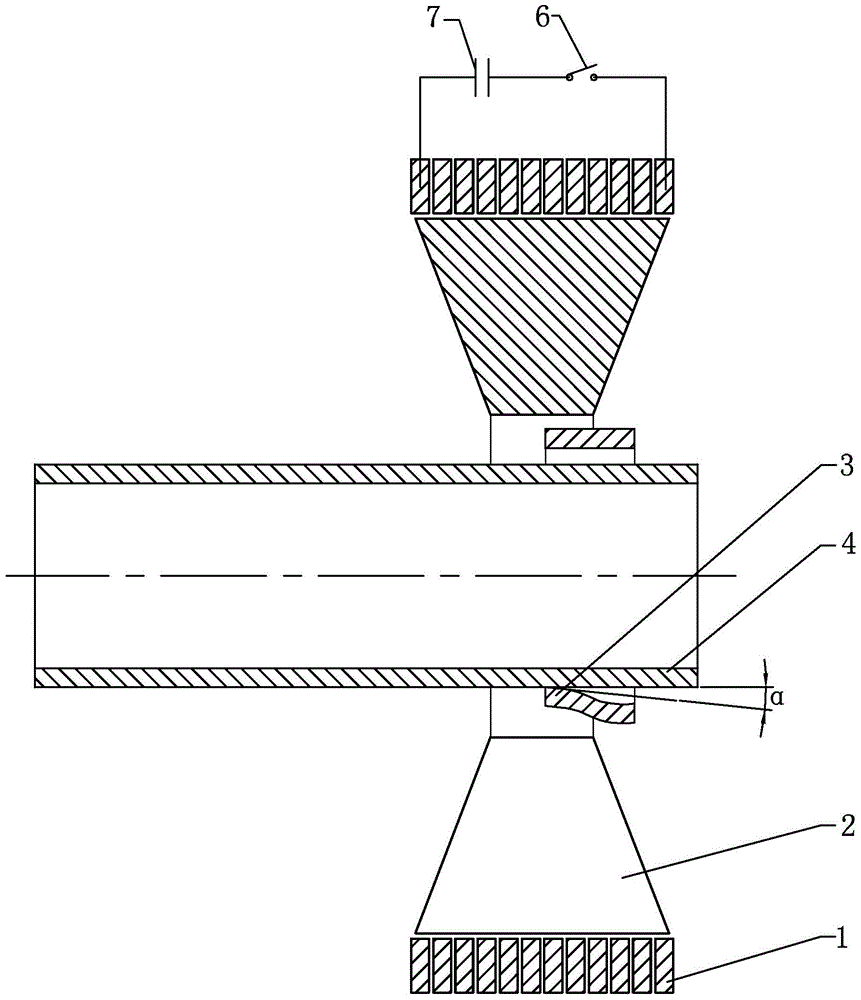

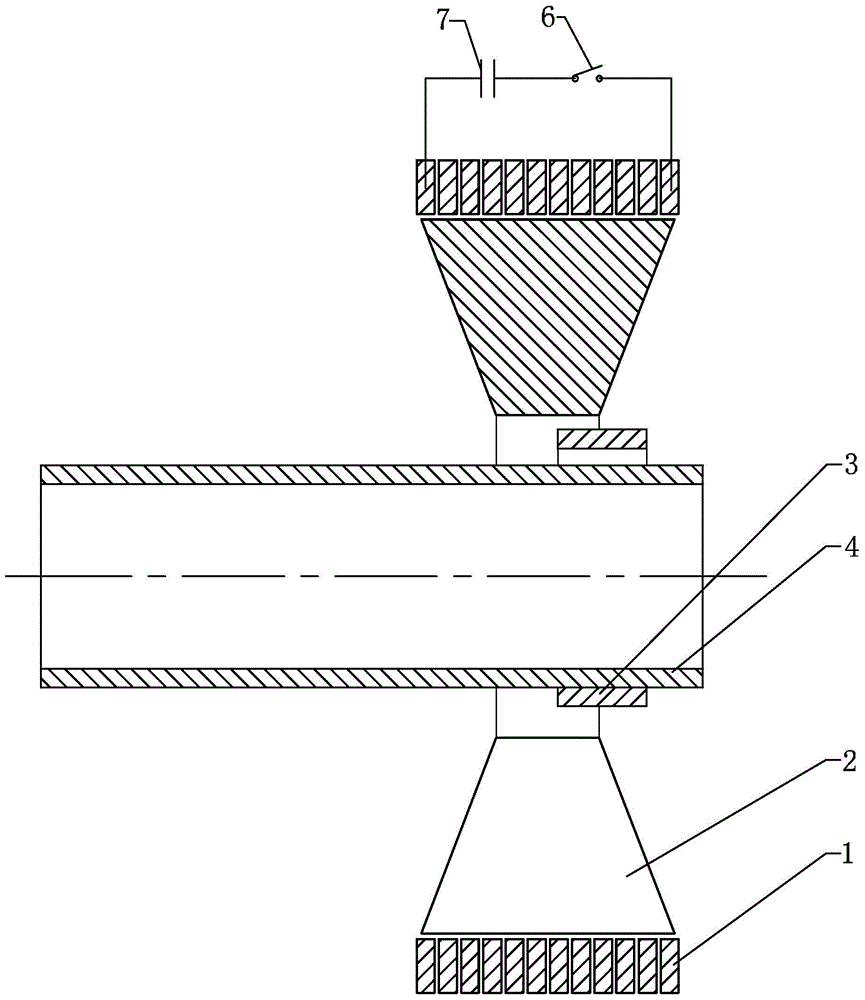

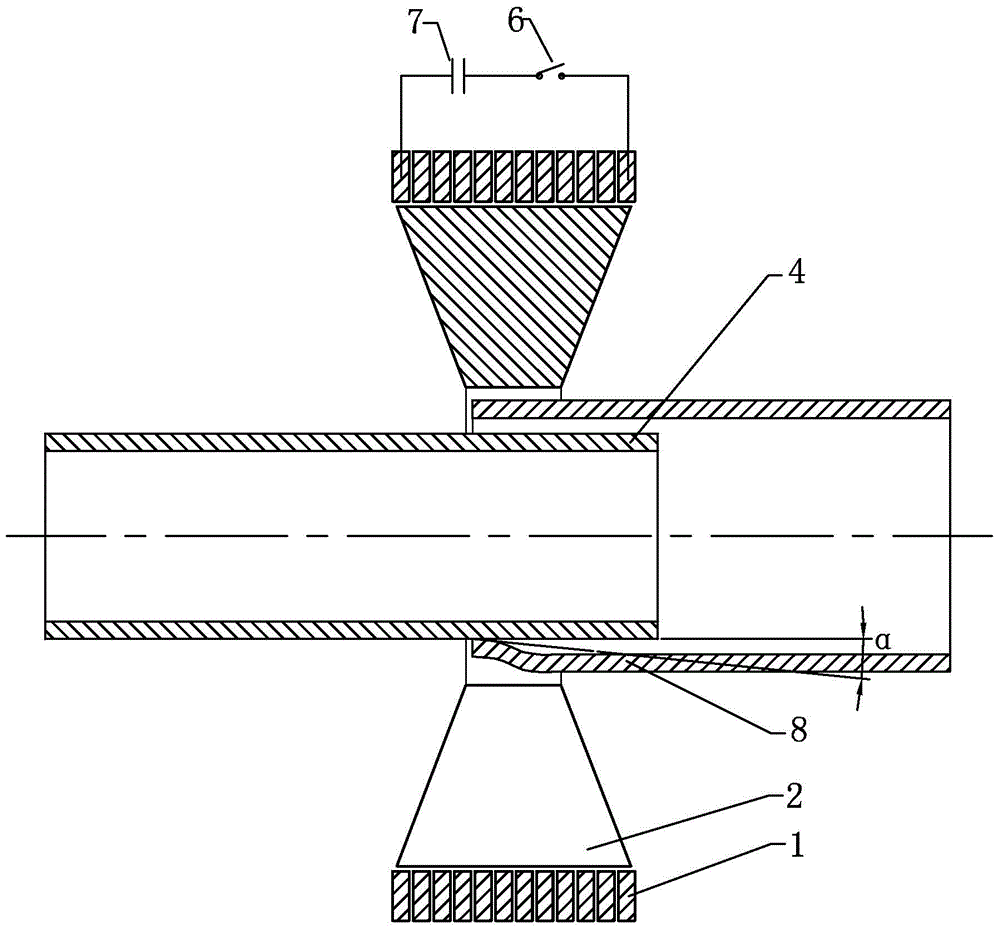

[0021] Specific implementation manner one: such as Figure 1a , Figure 1b , Figure 2a , Figure 2b As shown, the high-speed connection device of the dissimilar metal ring and the metal pipe assembly joint of this embodiment includes a solenoid coil 1, a magnetic collector 2, a discharge switch 6 and a capacitor bank 7. The central part of the magnetic collector 2 is provided with an axial through The inner cavity (the axial cross-sectional shape of the side wall of the magnetic collector 2 is an isosceles trapezoid), the length of the inner side of the magnetic collector 2 is less than the length of its outer side, and the side of the magnetic collector 2 is provided with an axially communicating with the inner cavity of the magnetic collector 2 In the longitudinal seam, the solenoid coil 1 is sleeved on the outside of the magnetic collector 2. The solenoid coil 1 and the magnetic collector 2 are arranged coaxially. One end of the capacitor bank 7 is connected to a terminal of ...

specific Embodiment approach 2

[0022] Specific implementation manner two: combination Figure 1a , Figure 1b It is explained that a method of this embodiment uses the high-speed connecting device to realize the connection method of the dissimilar metal ring and the metal pipe fitting assembly joint, and the method includes the following steps:

[0023] Step 1: Set the metal pipe 4 in the inner cavity of the magnetic collector 2 first, set the metal ring 3 on the metal pipe 4, and charge the capacitor bank 7 to a preset voltage according to the principle of the magnetic pulse forming process ;

[0024] Step 2: After the capacitor bank 7 is charged, the discharge switch 6 is closed, and the electric energy stored in the capacitor bank 7 is discharged to the solenoid coil 1 through the lead wire. The current passing through the solenoid coil 1 has the characteristics of instantaneous attenuation and oscillation, according to The law of electromagnetic induction and the skin effect produce induced current on the out...

specific Embodiment approach 3

[0026] Specific implementation mode three: combination Figure 1a , Figure 1b It is explained that in step one of this embodiment, the capacitor bank 7 is charged to 3-20kV; in step two, when the impact velocity at the contact point reaches 210-300m / s, between the inner surface of the metal ring 3 and the outer surface of the metal pipe 4 When the formed acute angle α is 10°, the axial movement speed of the contact point reaches 1100 to 1700 m / s. Severe shear deformation causes the thin layer of metal to peel off from the inner and outer surfaces of the metal pipe, and fly out from the front end of the impact contact point together with oxide and air, forming a jet phenomenon, so that the surface to be connected is exposed to clean metal under the impact pressure , Forming a metallurgical bonding interface. The technical features not disclosed in the embodiment are the same as those in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com