Completely-biodegradable casting polypropylene film and manufacturing method thereof

A salivating polypropylene, biodegradation technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, coatings, etc., can solve the problems of reduced mechanical properties of plastics, limited utilization of solar radiation, etc., to achieve good degradation effect, The effect of achieving degradation controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

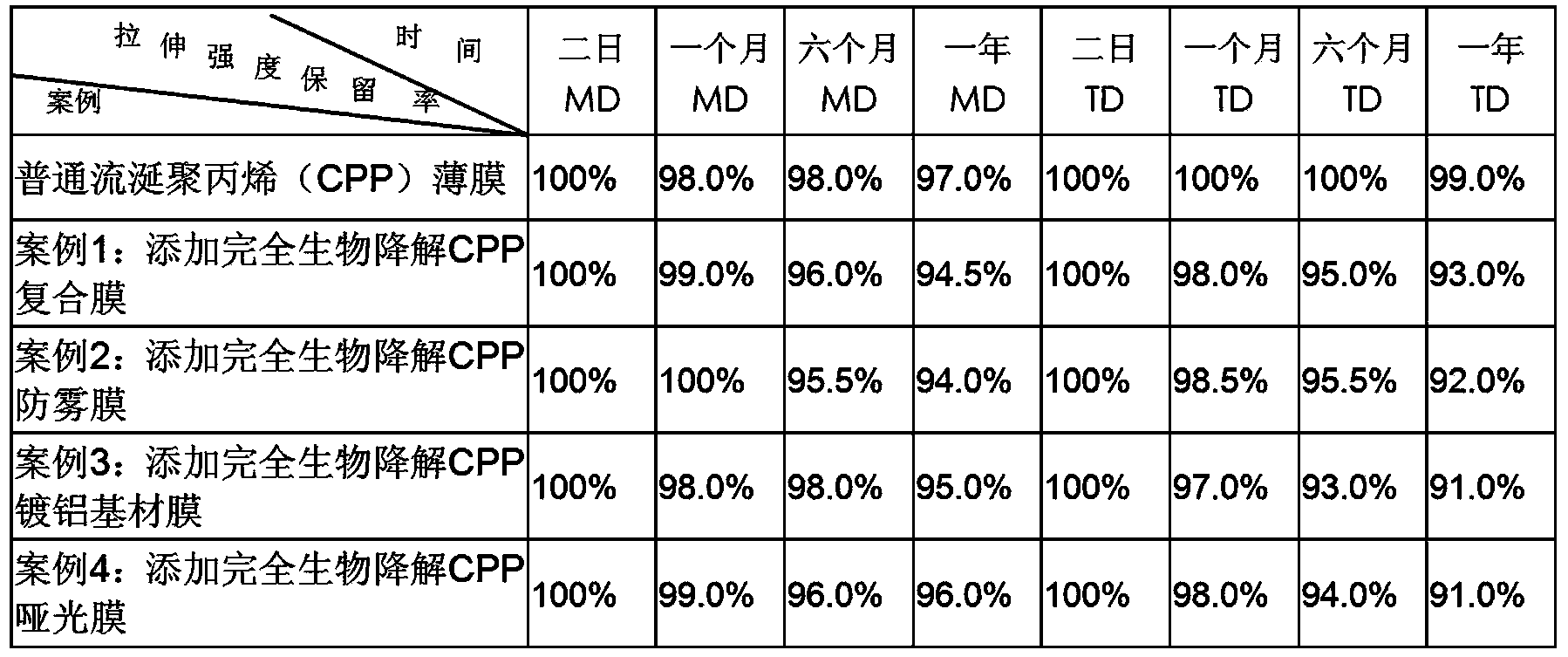

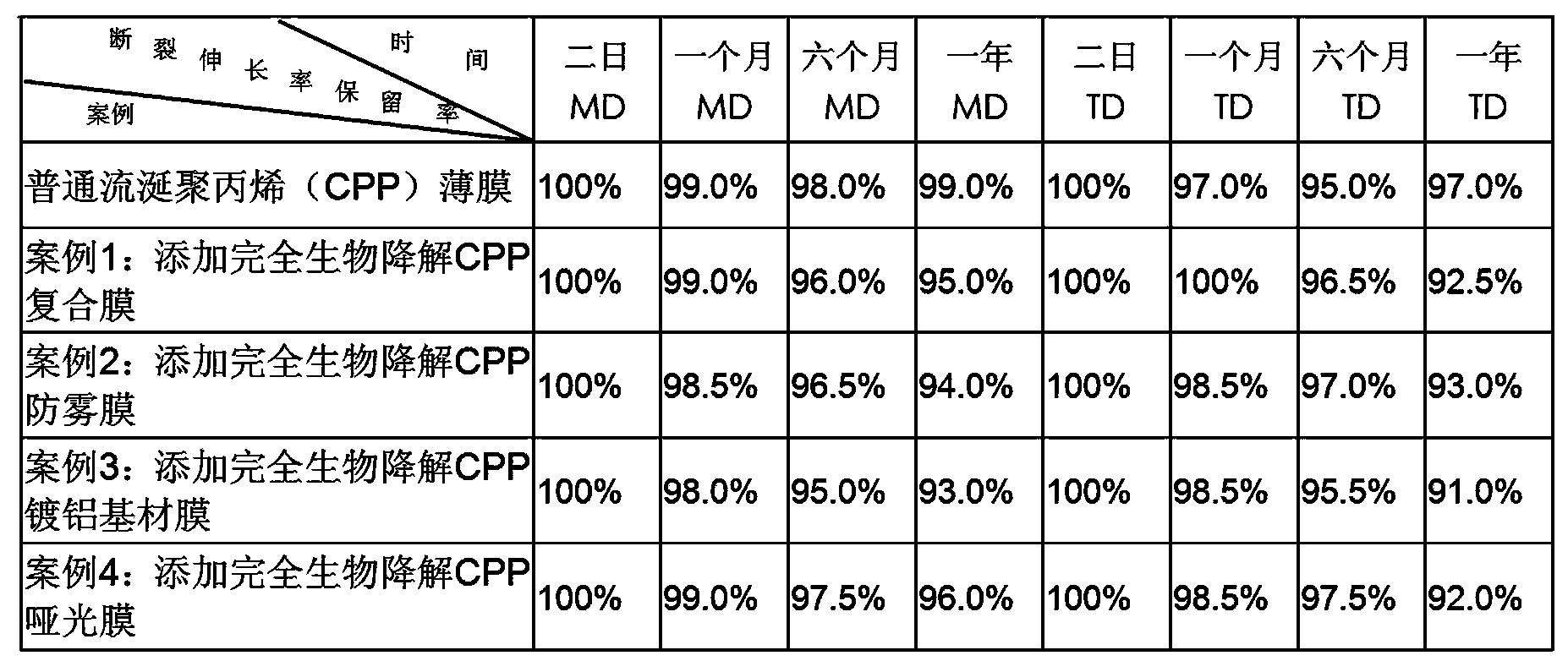

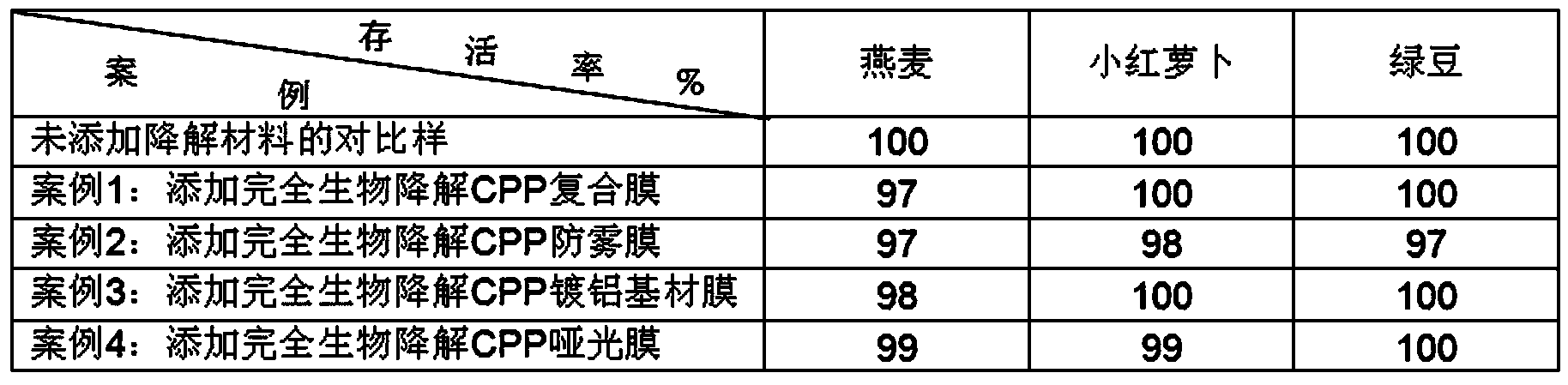

[0040] Embodiment 1: A kind of fully biodegradable salivating polypropylene (CPP) composite film, its outer layer selects the weight percentage to be respectively 96.5% of copolymerized polypropylene, anti-adhesion masterbatch 2.5% AB05PS, the component preparation of completely biodegradable material 1.0% and the melt index of the copolymerized polypropylene ranges from 5.5 to 8.0 g / 10min; the core layer is selected from the components of homopolypropylene 97.5%, smooth masterbatch 1.5% SE07PP, and fully biodegradable material 1.0% by weight. The melt index range of homopolypropylene is 2.8-8.5 g / 10min; the inner surface layer is made of homopolypropylene 96.5%, anti-adhesion masterbatch 2.5% AB05PS, and fully biodegradable material 1.0% by weight. The melt index range of homopolypropylene is 2.8-8.5 g / 10min; the thickness of the outer layer is controlled at 5 μ, the thickness of the core layer is controlled at 29.5 μ, and the thickness of the inner layer is controlled at 4.5 ...

Embodiment 2

[0042] Example 2: A completely biodegradable salivating polypropylene (CPP) anti-fog film, the outer layer of which is selected from a composition of 96.5% by weight of copolymerized polypropylene, 2.5% of anti-adhesion masterbatch AB05PS, and 1.0% of completely biodegradable materials. and the melt index range of the copolymerized polypropylene is 5.5-8.0 g / 10min; the weight percentages of the core layer are homopolypropylene 96.0%, smooth masterbatch 0.5% SE07PP, anti-fog masterbatch 2.5% AF20PP1, complete It is made of biodegradable materials with 1.0% components, and the melt index range of homopolypropylene is 2.8-8.5 g / 10min; the inner and surface layers are made of copolymer polypropylene 95.0%, anti-adhesion masterbatch 2.5% AB05PS, anti-adhesion Fog masterbatch 1.5% AF20PP1, fully biodegradable material 1.0% is formulated, and the melt index range of copolymerized polypropylene is 5.5-8.0g / 10min; the thickness of the outer layer is controlled at 5μ, and the thickness o...

Embodiment 3

[0044] Embodiment 3: A completely biodegradable salivating polypropylene (CPP) aluminized substrate film, the outer layer of which is selected from the group consisting of 96% by weight of copolymerized polypropylene, 3% of anti-blocking masterbatch AB05PS, and 1.0% of completely biodegradable materials. The melt index range of the copolymerized polypropylene is 5.5-8.0 g / 10min; the core layer is made of components with the weight percentages of homopolypropylene 99% and fully biodegradable materials 1.0%, and both The melt index of polypropylene ranges from 2.8 to 8.5 g / 10min. The inner surface layer is made of components whose weight percent is respectively 99.0% of copolymerized polypropylene and 1.0% of completely biodegradable material, and the melt index range of the copolymerized polypropylene is 5.5-8.0 g / 10min. The thickness of the outer surface layer is controlled to be 5μ, the thickness of the core layer is controlled to be 15.5μ, and the thickness of the inner surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com