Method for purifying hydrogen chloride by adopting anhydrous calcium chloride

An anhydrous calcium chloride, hydrogen chloride technology, applied in chlorine/hydrogen chloride, chloride preparation and other directions, can solve problems such as difficult separation, achieve the effect of recovery and reuse, significant environmental and economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

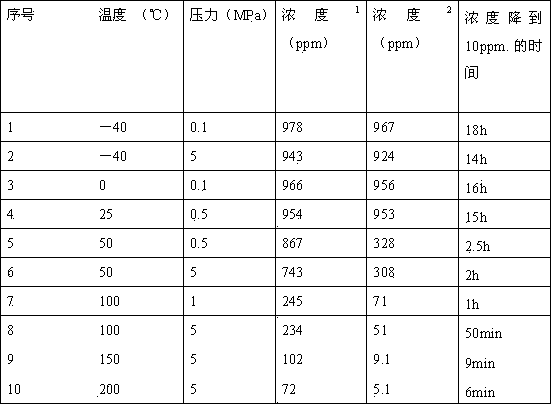

[0026] Example Add 100g of activated anhydrous calcium chloride into a 500mL pressure reactor, then pass hydrogen chloride gas with a hydrogen fluoride concentration of 1000ppm into the reactor, and control the pressure of the reactor at 0.1 to 5MPa, reflecting the temperature -40°C to 200 Within the range of ℃, the reaction time is 5min-18h, as shown in Table 1:

[0027] Table 1: Reaction conditions and results of Examples 1-10

[0028]

[0029] Among them, the superscript 1 of the concentration indicates the concentration of HF reacted for 1 min; the superscript 2 of the concentration indicates the concentration of HF reacted for 10 min.

[0030] As described in the above examples and Table 1, it can be seen that under the process conditions of reactor pressure of 0.1MPa~5Mpa, reaction temperature of -40°C~200°C, and reaction time of 6 minutes to 18 hours, the concentration of HF can be reduced to About 1000ppm of hydrogen chloride is purified to a concentration of HF as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com