Method for preparing nanometer zinc oxide with micro-emulsion

A technology of nano-zinc oxide and micro-emulsion, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of high cost and insufficient experimental conditions, and achieve low cost, mild experimental conditions and high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

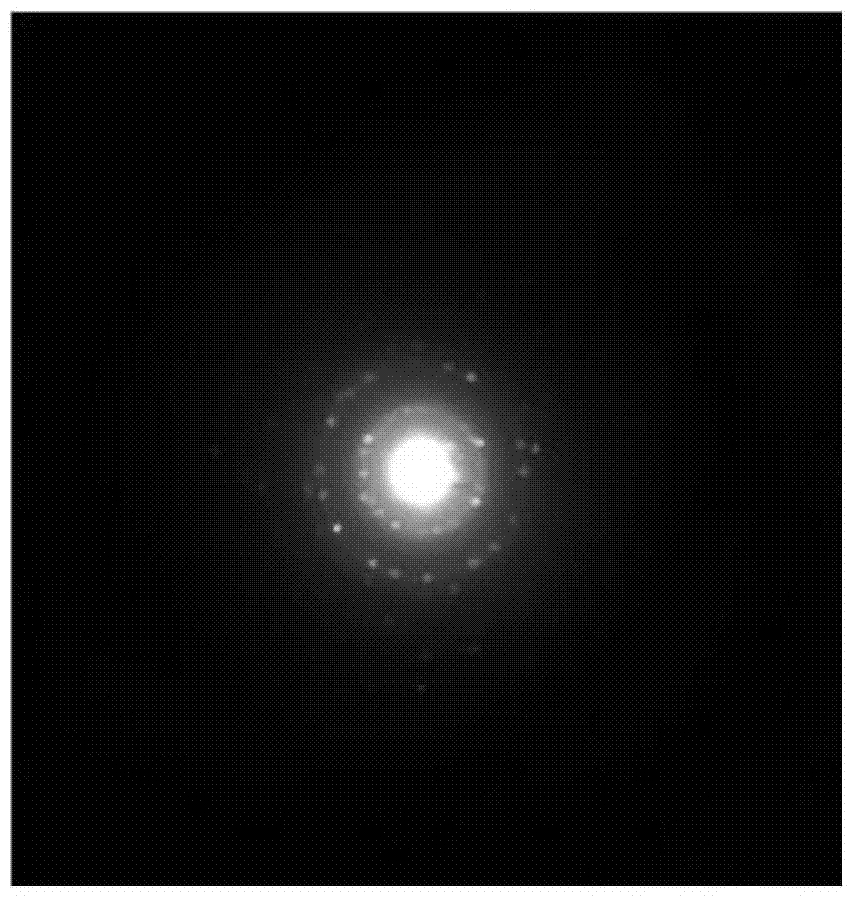

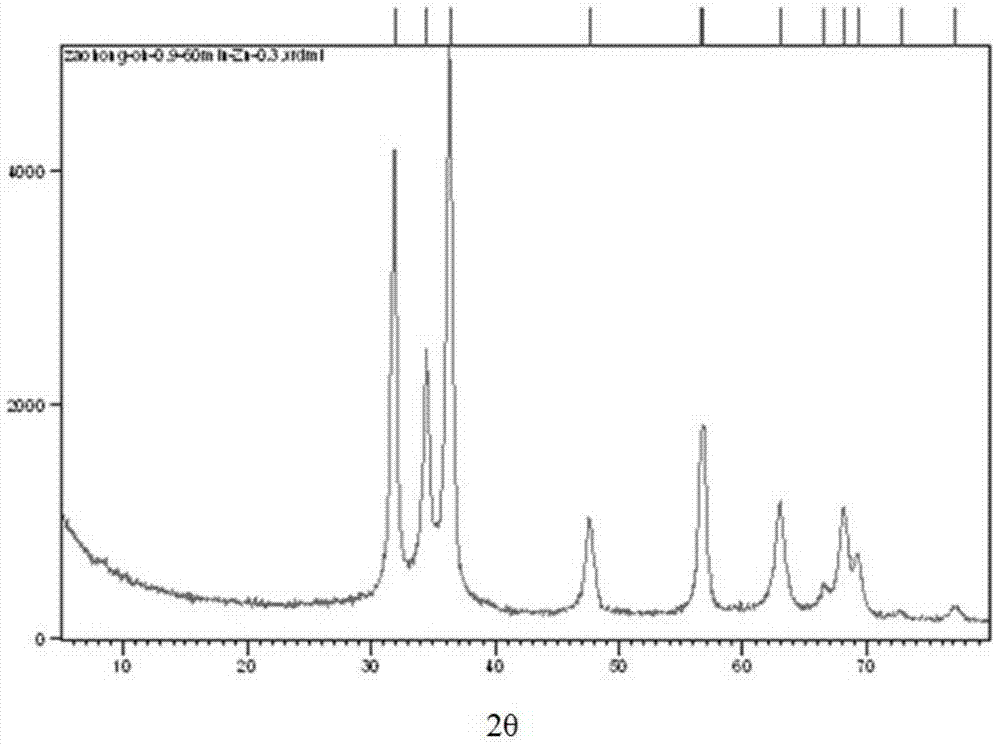

Image

Examples

Embodiment 1

[0030] Step 1: SDS / n-pentanol-cyclohexane-0.2mol / l zinc nitrate solution and SDS / n-pentanol-cyclohexane-0.6mol / lNaOH microemulsion respectively according to the volume ratio of 1:1. Pentanol-cyclohexane-0.2mol / l zinc nitrate solution is placed in a flask, the flask is placed in a constant temperature water bath, and a stirring device is added, and the SDS / n-pentanol-cyclohexane-0.6mol is mixed with a constant pressure funnel / lNaOH microemulsion was dripped into the flask equipped with SDS / n-pentanol-cyclohexane-0.2mol / l zinc nitrate solution in a 30°C constant temperature tank, and stirred for 15 minutes after the titration was completed to obtain a milky white liquid;

[0031] Step 2: Centrifuge the milky white liquid obtained in step 1 to separate the ultrafine particles from the microemulsion. During the centrifugation process, wash with absolute ethanol for 3 times, water for 3 times, and absolute ethanol for one more time. Dry in vacuum for 4 hours to obtain nanometer zi...

Embodiment 2

[0033] Step 1: SDS / n-pentanol-cyclohexane-0.3mol / l zinc nitrate solution and SDS / n-pentanol-cyclohexane-0.7mol / lNaOH microemulsion respectively according to the volume ratio of 2:3, the SDS / n- Pentanol-cyclohexane-0.3mol / l zinc nitrate solution is placed in a flask, the flask is placed in a constant temperature water bath, and a stirring device is added, and the SDS / n-pentanol-cyclohexane-0.7mol is mixed with a constant pressure funnel / lNaOH microemulsion was dropped into the flask equipped with SDS / n-pentanol-cyclohexane-0.3mol / l zinc nitrate solution in a 70°C constant temperature tank, and stirred for 10 minutes after the titration was completed to obtain a milky white liquid;

[0034] Step 2: Centrifuge the milky white liquid obtained in step 1 to separate the ultrafine particles from the microemulsion. During the centrifugation process, wash with absolute ethanol for 3 times, water for 3 times, and absolute ethanol for one more time. Dry in vacuum for 4 hours to obtain n...

Embodiment 3

[0036] Step 1: SDS / n-pentanol-cyclohexane-0.4mol / l zinc nitrate solution and SDS / n-pentanol-cyclohexane-0.8mol / lNaOH microemulsion respectively according to the volume ratio of 3:2, the SDS / n- Pentanol-cyclohexane-0.4mol / l zinc nitrate solution is placed in a flask, the flask is placed in a constant temperature water bath, and a stirring device is added, and the SDS / n-pentanol-cyclohexane-0.8mol is mixed with a constant pressure funnel / lNaOH microemulsion was dripped into a flask equipped with SDS / n-pentanol-cyclohexane-0.4mol / l zinc nitrate solution in a 60°C constant temperature tank, and stirred for 12 minutes after the titration was completed to obtain a milky white liquid;

[0037] Step 2: Centrifuge the milky white liquid obtained in step 1 to separate the ultrafine particles from the microemulsion. During the centrifugation process, wash with absolute ethanol for 3 times, water for 3 times, and absolute ethanol for one more time. Dry in vacuum for 4 hours to obtain nan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com