Method for cultivating high strength aerobic granular sludge

A technology of aerobic granular sludge and cultivation methods, applied in chemical instruments and methods, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problem of biomass loss, disintegration, and influence on process operation efficiency and other issues to achieve the effect of rapid cultivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

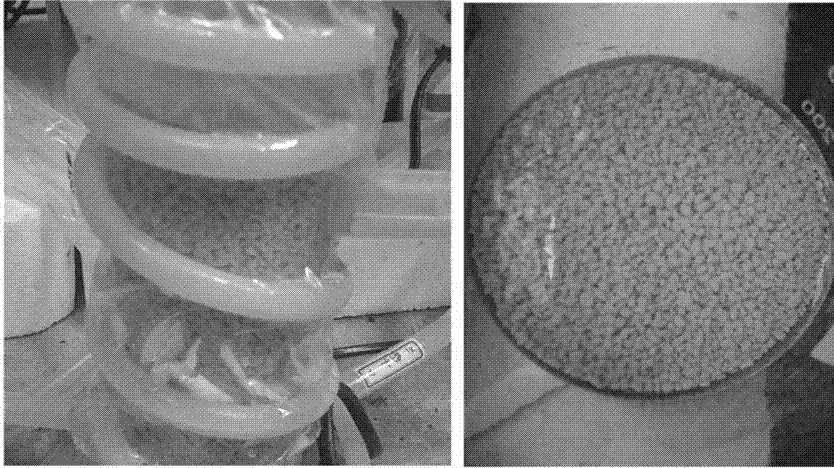

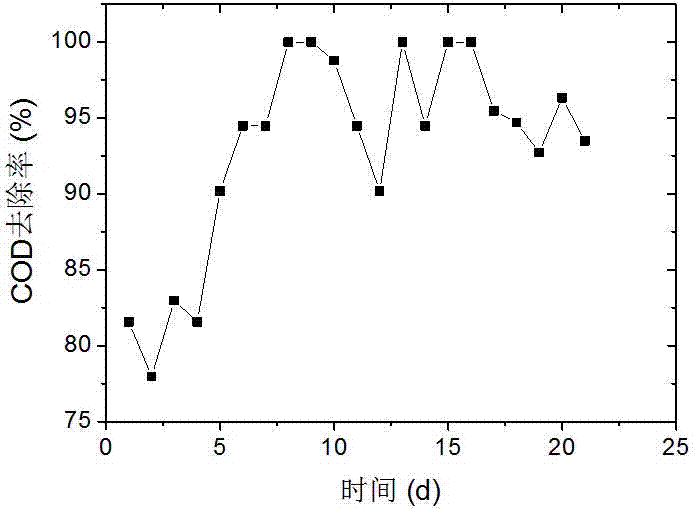

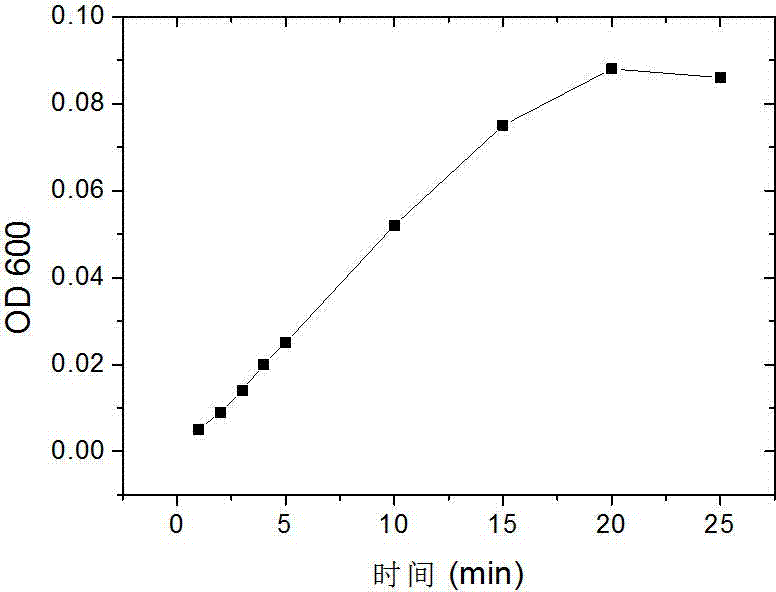

[0024] Embodiment 1, the cultivation of aerobic granular sludge

[0025] The flocculent return sludge retrieved from a sewage treatment plant in Shanghai was settled at room temperature, the supernatant was removed, and the concentration of concentrated activated sludge was determined to be 19714 mg / L. At room temperature, 700 mL of sludge was inoculated into an SBR reactor with an effective volume of 2.3 L. Each operation cycle is divided into five stages: water intake-aeration-sedimentation-drainage-idle. During the water inflow period, start the inflow pump to inject synthetic sewage into the reactor. After reaching the effective volume of the reactor, stop the water inflow for 3 minutes; the aeration stage and the settlement stage are 227 minutes in total, and the aeration rate is 5 L / min. During the sludge cultivation period, the process was divided into six stages, and the sedimentation time of the sludge was adjusted according to different operation stages. The speci...

Embodiment 2

[0026] Embodiment 2, the cultivation of aerobic granular sludge

[0027] The flocculent return sludge retrieved from a sewage treatment plant in Shanghai was settled at room temperature, the supernatant was removed, and the concentration of concentrated activated sludge was determined to be 19714 mg / L. At room temperature, 700 mL of sludge was inoculated into an SBR reactor with an effective volume of 2.3 L. Each operation cycle is divided into five stages: water intake-aeration-sedimentation-drainage-idle. During the water inflow period, start the inflow pump to inject synthetic sewage into the reactor. After reaching the effective volume of the reactor, stop the water inflow for 3 minutes; the aeration stage and the settlement stage are 227 minutes in total, and the aeration rate is 3 L / min. During the sludge cultivation period, the process was divided into six stages, and the sedimentation time of the sludge was adjusted according to different operation stages. The speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com