Concrete retarder and preparation method thereof

A retarder and concrete technology, applied in the chemical industry, can solve the problems of insufficient sodium gluconate retardation, excessive non-condensation, etc., and achieve the effect of good retarding performance and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

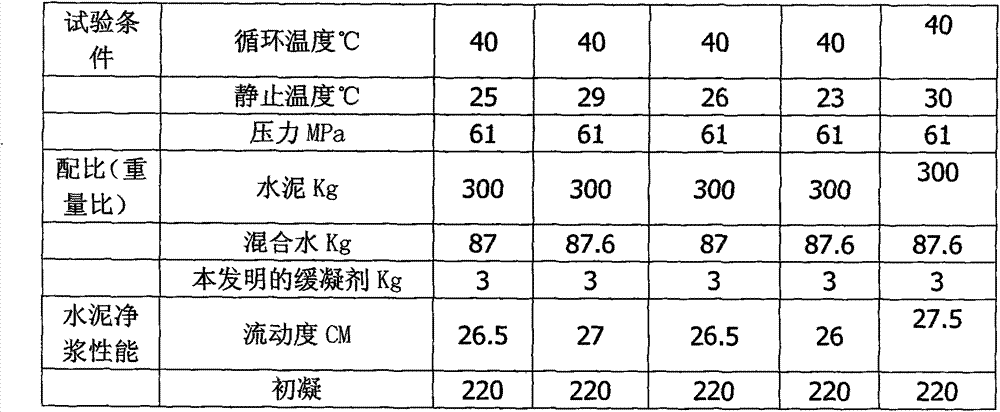

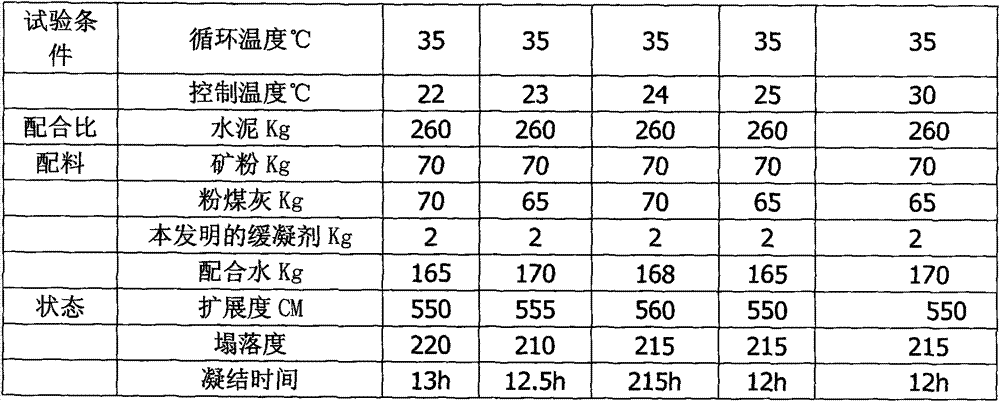

Examples

Embodiment 1

[0020] The concrete retarder of the present invention is composed of the following raw materials in percentage by weight: syrup 15%, disaccharide 10%, anion 30%, sodium phosphate 8%, sodium tripolyphosphate 5%, ammonium persulfate 8%, water 24% .

[0021] The specific steps of the method for preparing the concrete retarder are as follows: adjust the temperature of the purchased disaccharide to above 0°C, dissolve and release the disaccharide and the syrup with a weight ratio of 50% each, dissolve for 10-20min, fully stir evenly, and heat When the temperature reaches 20°C, start to add ammonium persulfate dropwise, dissolve 5% of the total weight in water and add dropwise at a high level, react for half an hour, control the temperature at 20°C±2, keep for 20min after the reaction is completed, then add anion, sodium phosphate, tris The sodium polyphosphate component was stirred for 10 minutes to prepare the concrete retarder.

Embodiment 2

[0023] The concrete retarder of the present invention is composed of the following raw materials in percentage by weight: syrup 40%, disaccharide 5%, anion 20%, sodium phosphate 3%, sodium tripolyphosphate 1%, ammonium persulfate 3%, water 28% .

[0024] The preparation method is the same as in Example 1.

Embodiment 3

[0026] Concrete retarder of the present invention is made up of the raw material of following percentage by weight:

[0027] Syrup 30%, disaccharide 8%, anion 25%, sodium phosphate 5%, sodium tripolyphosphate 3%, ammonium persulfate 5%, water 24%.

[0028] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com