Method for preparing thermosetting phenol resin

A phenolic resin and thermosetting technology, applied in the field of preparation of thermosetting phenolic resin, can solve problems such as factors and dangers that increase environmental impact, influence of resin use, influence of equipment and process stability, etc., and achieve easy control, stable quality, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

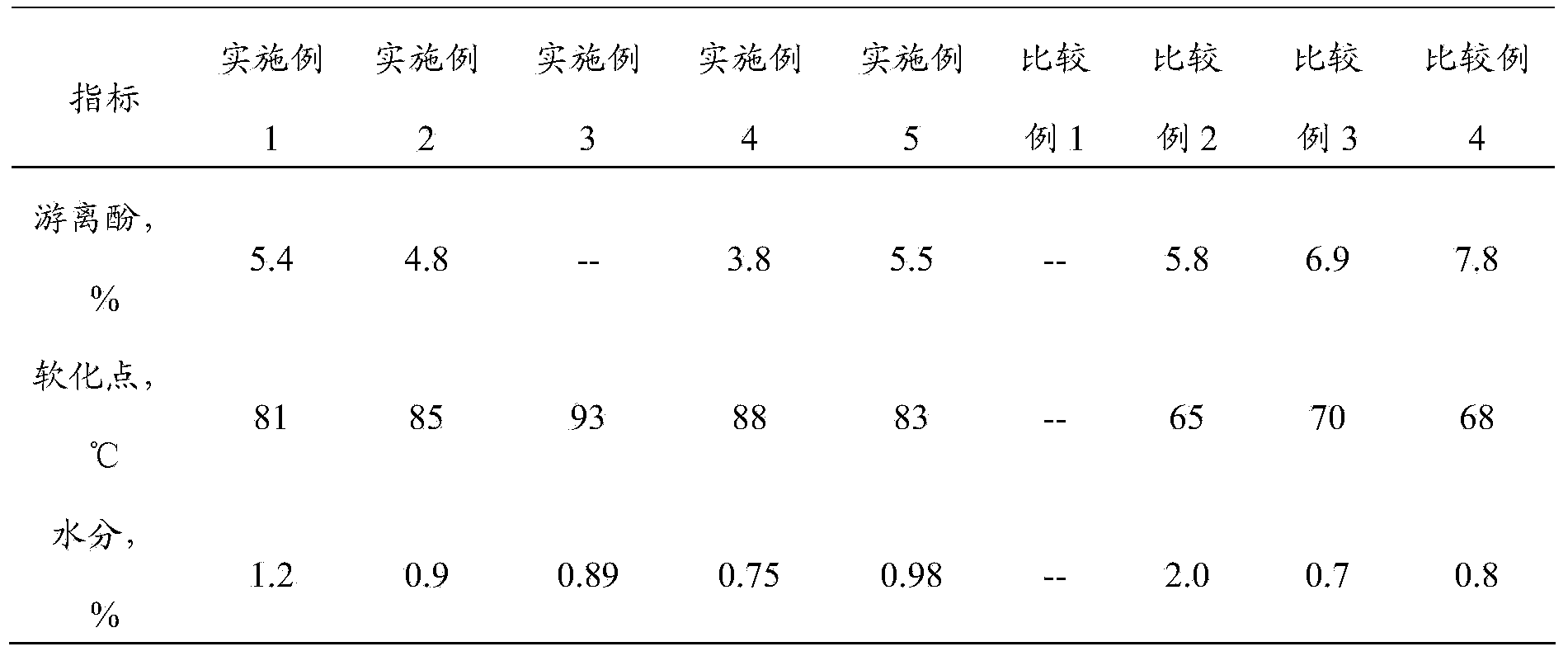

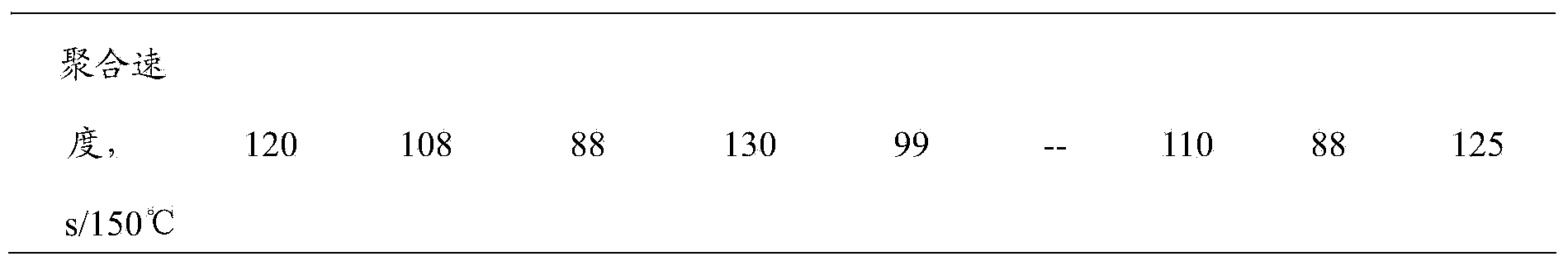

[0041] Add 940 parts by weight of phenol, 1090 parts by weight of 44% formaldehyde, 9.4 parts by weight of calcium oxide and 120 parts by weight of ethylenediamine into a 3000ml reaction vessel with a thermometer, a stirring device, and a reflux condenser, and heat for 1.5h to After reacting at 100°C for 4 hours, let it stand for 20 minutes to separate out 489 parts by weight of water, raise the temperature of the remaining resin layer and maintain a vacuum pressure of -0.095MPa for dehydration, control the dehydration temperature below 95°C, and use the ring and ball method to test the softening point of the resin It reached 81° C., and 1128 parts by weight of a thermosetting phenolic resin were obtained.

[0042] The thermosetting phenolic resin obtained in Example 1 was tested for performance, and the results obtained are shown in Table 1.

Embodiment 2

[0044] Add 940 parts by weight of phenol, 1227 parts by weight of 44% formaldehyde, and 3 parts by weight of zinc oxide into a 3000ml reaction vessel equipped with a thermometer, a stirring device, and a reflux condenser, heat for 1.5 hours and raise the temperature to 100°C for 2.5 hours, then cool down to 55°C, add 206 parts by weight of diethylenetriamine, heat to 70°C for 2 hours, let it stand for 20 minutes, separate 1028 parts by weight of water, wash the remaining resin layer with 500 parts by weight of water at 55°C, and separate 476 parts by weight of water Then the resin is heated up and dehydrated under a vacuum pressure of -0.095MPa, the dehydration temperature is controlled below 95°C, and the softening point of the resin is tested by the ring and ball method to reach 85°C to obtain 1316 parts by weight of thermosetting phenolic resin.

[0045] The thermosetting phenolic resin obtained in Example 2 was tested for performance, and the results obtained are shown in T...

Embodiment 3

[0047]Add 2280 parts by weight of bisphenol A, 886 parts by weight of 44% formaldehyde, 34 parts by weight of zinc acetate and 120 parts by weight of ethylenediamine into a 5000ml reaction vessel with a thermometer, a stirring device and a reflux condenser, and heat for 1.5h After heating up to 100°C for 3 hours, let stand for 20 minutes, separate 506 parts by weight of water, wash the remaining resin layer with 500 parts by weight of water, separate out 489 parts by weight of water, then raise the temperature of the resin and keep it at -0.095MPa Dehydration under vacuum pressure, the dehydration temperature is controlled below 95°C, the softening point of the resin reaches 93°C by ring and ball method, and 2736 parts by weight of thermosetting phenolic resin are obtained.

[0048] The thermosetting phenolic resin obtained in Example 3 was tested for performance, and the results obtained are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com