Preparation and catalysis behavior of highly dispersed zinc glutarate catalyst adopting silanization modified molecular sieve as carrier

A high-dispersity, zinc glutarate technology, applied in the fields of industrial catalysis and polymer chemistry, can solve the problems of high price and high toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

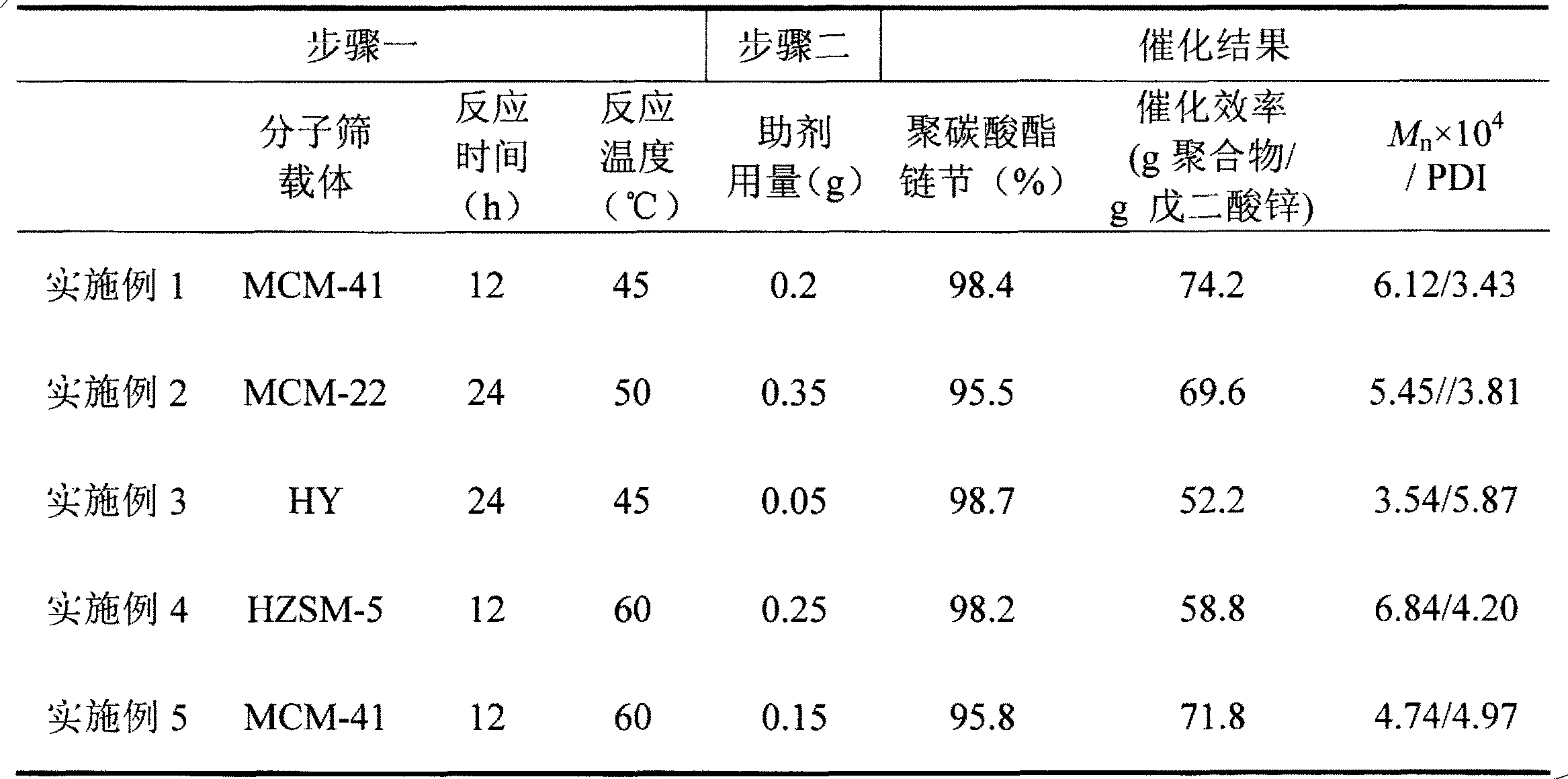

[0030] According to (embodiment: general operation) the preparation method of catalyzer, select MCM-41, MCM-22 for use, HY and HZSM-5 are selected as molecular sieve carrier, select different silanization reaction times and reaction temperature, step 2 in step 1 Different organic solvents, and carry out catalytic reaction strictly according to the catalytic condition in (embodiment: general operation), the obtained catalytic efficiency and polymer structure are shown in Table 1.

[0031] Table 1 Preparation conditions of highly dispersed zinc glutarate catalyst supported by silanized modified molecular sieve and its catalytic CO 2 Copolymerization results with propylene oxide:

[0032]

Embodiment 6~11

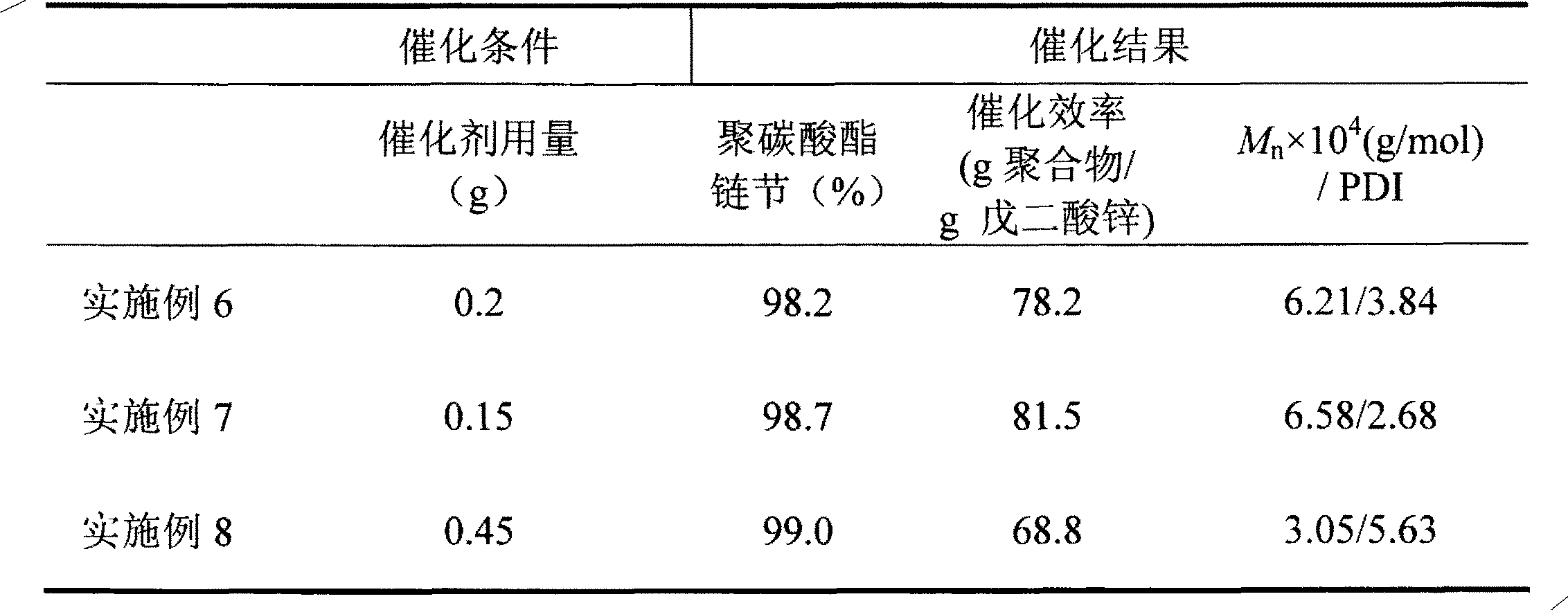

[0034] The same catalyst was synthesized according to the preparation method of Example 1, and the amount of the catalyst was changed. Other catalytic conditions were the same as those in Example 1. The obtained catalytic efficiency and polymer structure are shown in Table 2.

[0035] Table 2 Highly dispersed zinc glutarate catalysts supported by silanized modified molecular sieves catalyzed CO 2 Copolymerization results with propylene oxide:

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com