Resin type joint mixture

A caulking, resin-based technology, used in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of poor low-temperature adhesion and durability, peeling off of walls, affecting aesthetics, etc. The effect of strong adhesion, improved bonding strength and improved leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

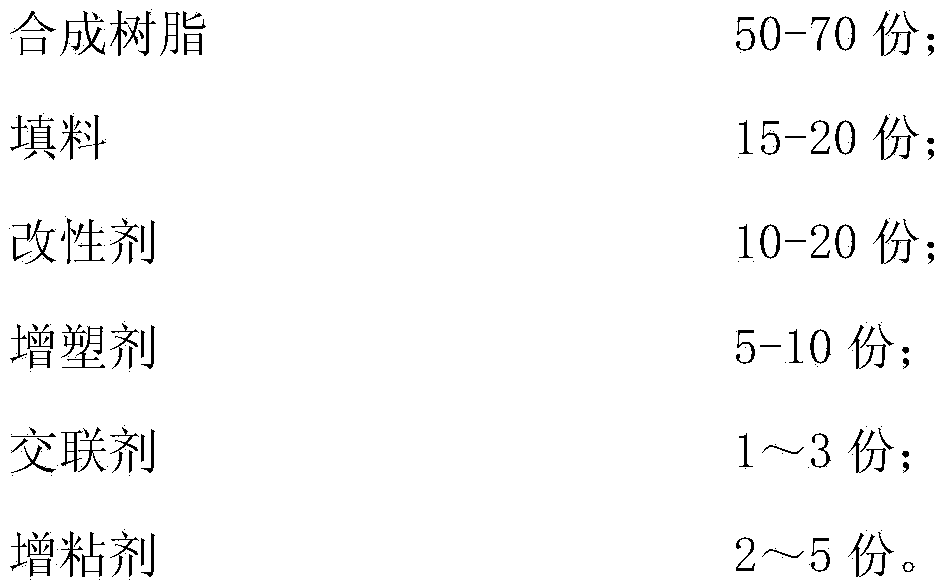

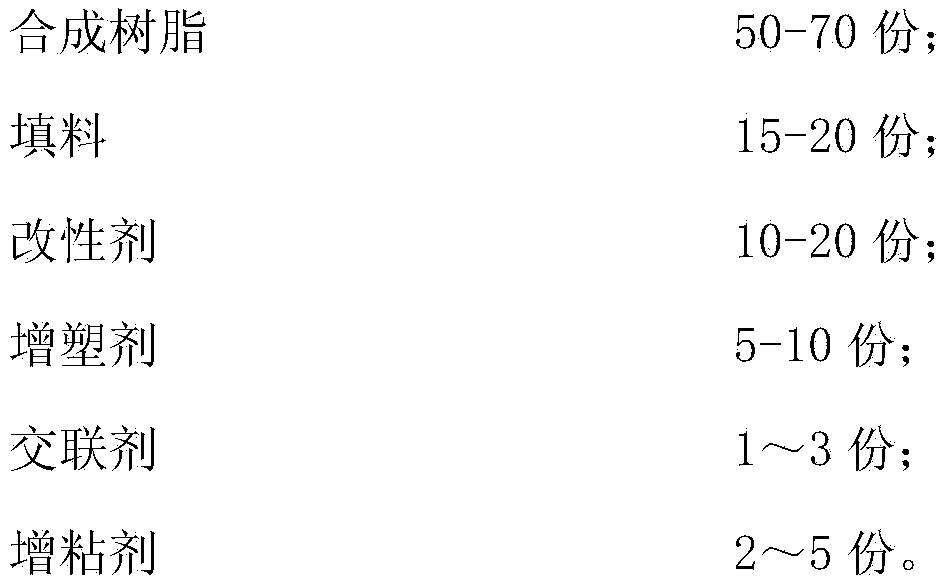

[0015] A resin-type caulking agent, comprising the following components in parts by weight: 50-70 parts of synthetic resin; 15 parts of barium sulfate; 10 parts of 107 silicone rubber; 5 parts of phthalate; 1 part of trimethylolpropane-tris(3-aziridinyl)propionate; 2 parts of anilinomethyltriethoxysilane.

Embodiment 2

[0017] A resin type caulking agent, comprising the following components in parts by weight: 50-70 parts of synthetic resin; 20 parts of calcium carbonate; 20 parts of 107 silicone rubber; 10 parts of phthalate; 3 parts of trimethylolpropane-tris(3-aziridinyl)propionate; 5 parts of anilinomethyltriethoxysilane.

Embodiment 3

[0019] A resin-type caulking agent, comprising the following components in parts by weight: 50-70 parts of synthetic resin; 18 parts of calcium carbonate; 15 parts of 107 silicone rubber; 8 parts of phthalate; 2 parts of trimethylolpropane-tris(3-aziridinyl) propionate; 3 parts of anilinomethyltriethoxysilane.

[0020] And it can be seen from Examples 1-3 that the joint strength, hardness and elasticity of the joint preparation prepared by the formula of the present invention are obviously improved, and the leveling of the joint joint is obviously improved. In addition, the The caulk also has excellent storage stability with long storage times. Therefore, the grout of the present invention is very suitable for tile grouting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com