Feeding device for biomass gasifier

A feeding device and biomass raw material technology, applied in the direction of granular/powdered fuel gasification, educts, chemical industry, etc., can solve insufficient gasification of biomass raw materials, reduce the calorific value of combustible gas, and affect catalyst catalysis Efficiency and other issues, to achieve the effect of simple structure, sufficient gasification, uniform and sufficient heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

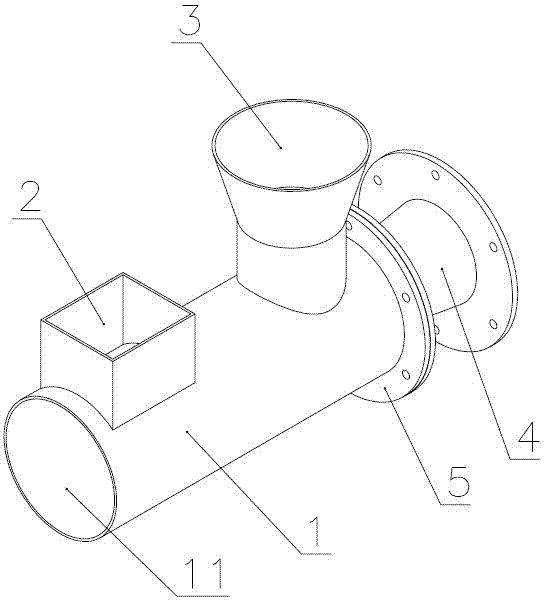

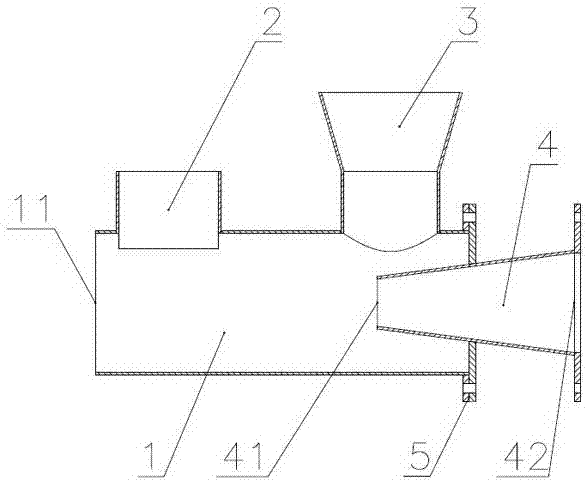

[0012] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0013] Such as figure 1 , figure 2 As shown, the feed device for the biomass gasification furnace described in this embodiment includes: a circular tube-shaped mixing chamber 1 and a conical-shaped hot-carrier gas inlet pipe 4, and the top end 41 of the hot-carrier gas inlet pipe The inner diameter of the inner diameter is less than the inner diameter of the heat carrier gas inlet pipe tail end 42; in the present embodiment, the cone angle of the heat carrier gas inlet pipe 4 of conical shape is 15 ± 5 °, and the heat carrier gas passes through the heat carrier gas inlet pipe The flow velocity of 4 is 15m / s~20m / s. The outlet 11 of the mixing chamber is connected to the feed port of the biomass gasifier, the inlet of the mixing chamber is connected to the hot carrier gas pipeline through the hot carrier g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com