Preparation method of dry red wine

A technology of dry red wine and grapes, which is applied in the field of wine preparation, can solve the problems of insufficient mellow aroma, poor taste, and insufficient wine body, and achieve good health care functions, full and coordinated wine body, and scientific and reasonable preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

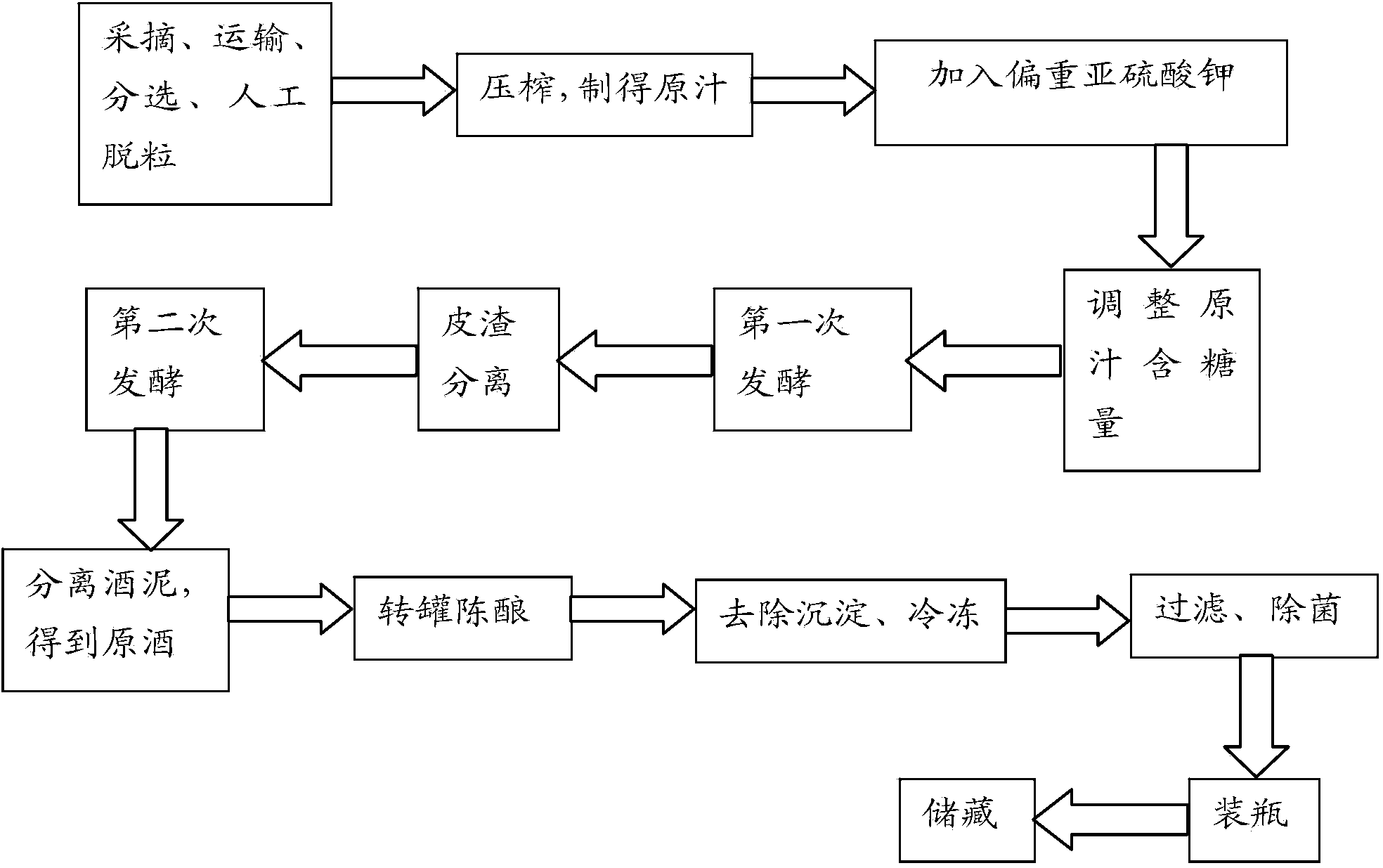

Method used

Image

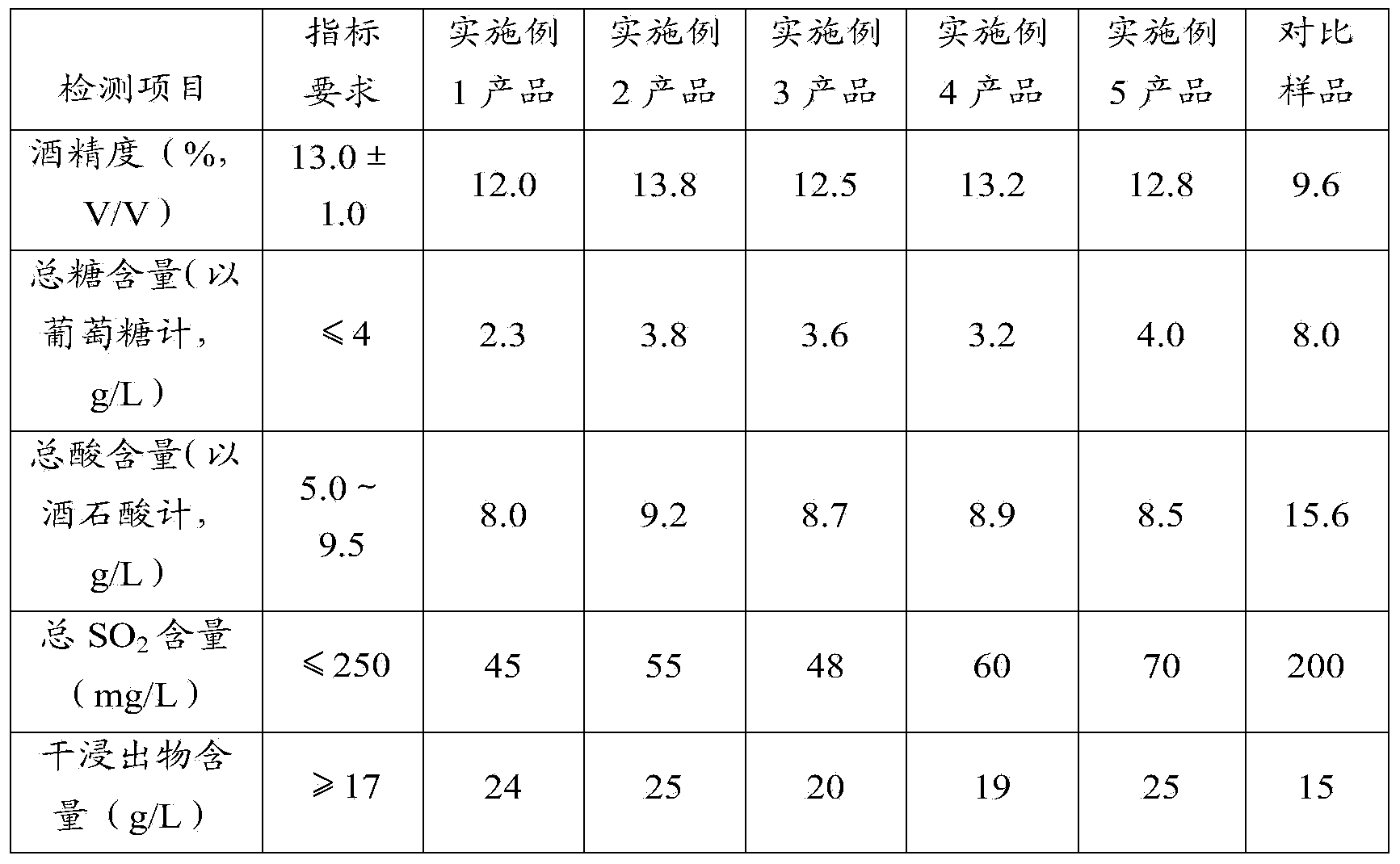

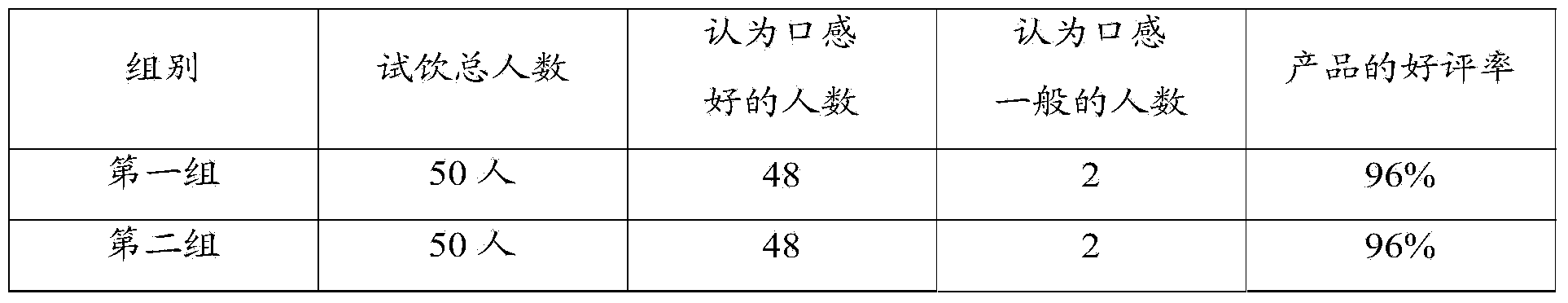

Examples

Embodiment 1

[0036] (1) Pre-treatment: Harvest when the color, hardness and sugar content of Arctic red grapes reach the mature characteristics of the variety, about September 15-25 each year; sort clean, disease-free, and non-damaged fruit ears; Manually use professional scissors to cut the intact fruit grains without fruit stalks, and remove green grains, diseased fruit grains and unclean fruit grains;

[0037] (2) Quickly crush the cut fruit pieces mechanically to obtain grape must;

[0038] (3) Add potassium metabisulfite according to the standard of 70g per ton of grape must;

[0039] (4) Add 3 times the white sugar to the grape mash treated in step (3), and then add it into the fermenter for stirring after it is completely dissolved, so that the sugar content of the grape mash treated in step (3) is 220g / L;

[0040] (5) Add Angel Yeast RV171 for the first fermentation, add Angel Yeast RV171 according to the standard of 150mg per liter of grape must, and the fermentation temperatur...

Embodiment 2

[0050] (1) Pre-treatment: Harvest when the color, hardness and sugar content of Arctic red grapes reach the mature characteristics of the variety, about September 15-25 each year; sort clean, disease-free, and non-damaged fruit ears; Manually use professional scissors to cut the intact fruit grains without fruit stalks, and remove green grains, diseased fruit grains and unclean fruit grains;

[0051] (2) Quickly crush the cut fruit pieces mechanically to obtain grape must;

[0052] (3) Add potassium metabisulfite according to the standard of 110g per ton of grape must;

[0053] (4) Add white granulated sugar to 7 times the grape must after step (3), and add it to the fermenter after it is completely dissolved, so that the sugar content of grape must after step (3) is 245g / L;

[0054](5) Add Angel Yeast RV171 for the first fermentation, add Angel Yeast RV171 according to the standard of 200mg per liter of grape must, and the fermentation temperature is 28°C; when the residua...

Embodiment 3

[0064] (1) Pre-treatment: Harvest when the color, hardness and sugar content of Arctic red grapes reach the mature characteristics of the variety, about September 15-25 every year; sort clean, disease-free, and non-damaged fruit ears; Manually use professional scissors to cut the intact fruit grains without fruit stalks, and remove green grains, diseased fruit grains and unclean fruit grains;

[0065] (2) Quickly crush the cut fruit pieces mechanically to obtain grape must;

[0066] (3) Add potassium metabisulfite according to the standard of 80g per ton of grape must;

[0067] (4) Add white granulated sugar to 3 times the grape must after step (3), and add it to the fermenter after it is completely dissolved, so that the sugar content of grape must after step (3) is 230g / L;

[0068] (5) Add Angel Yeast RV171 for the first fermentation, add Angel Yeast RV171 according to the standard of 160mg per liter of grape must, and the fermentation temperature is 25°C; when the residu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com