Preparation method of electrochromic intelligent fiber

An electrochromic and fiber technology, applied in the direction of cable/conductor manufacturing, circuit, electrolytic coating, etc., can solve the problems of unable to change the color intelligently, limit the application of fibers, etc., achieve good electrochromic performance, fast transition rate, obvious The effect of the gradient color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

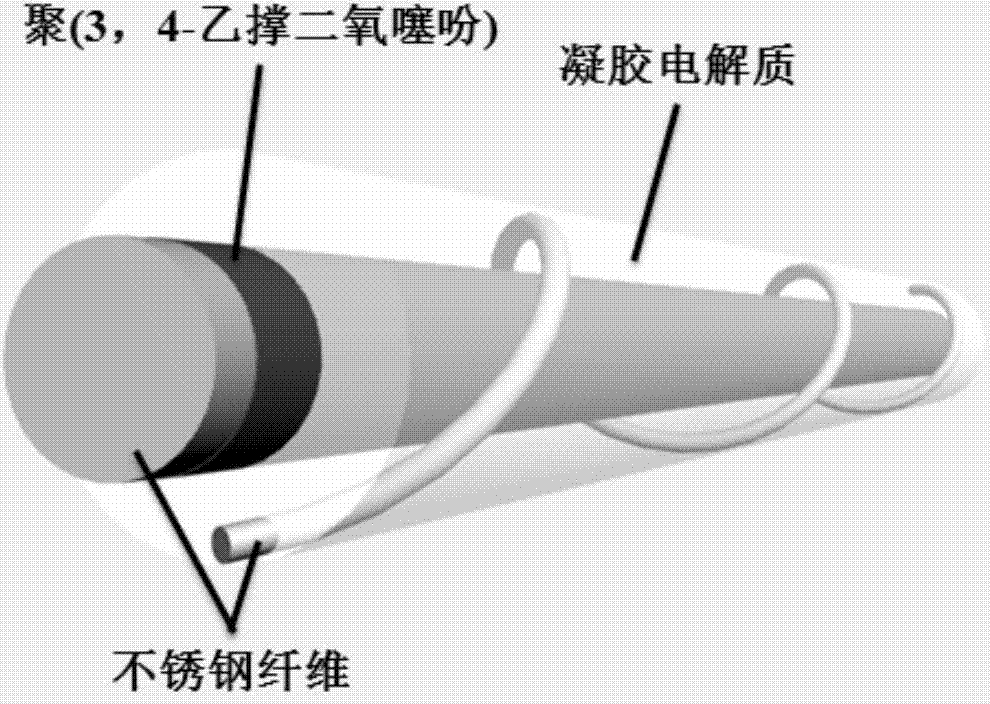

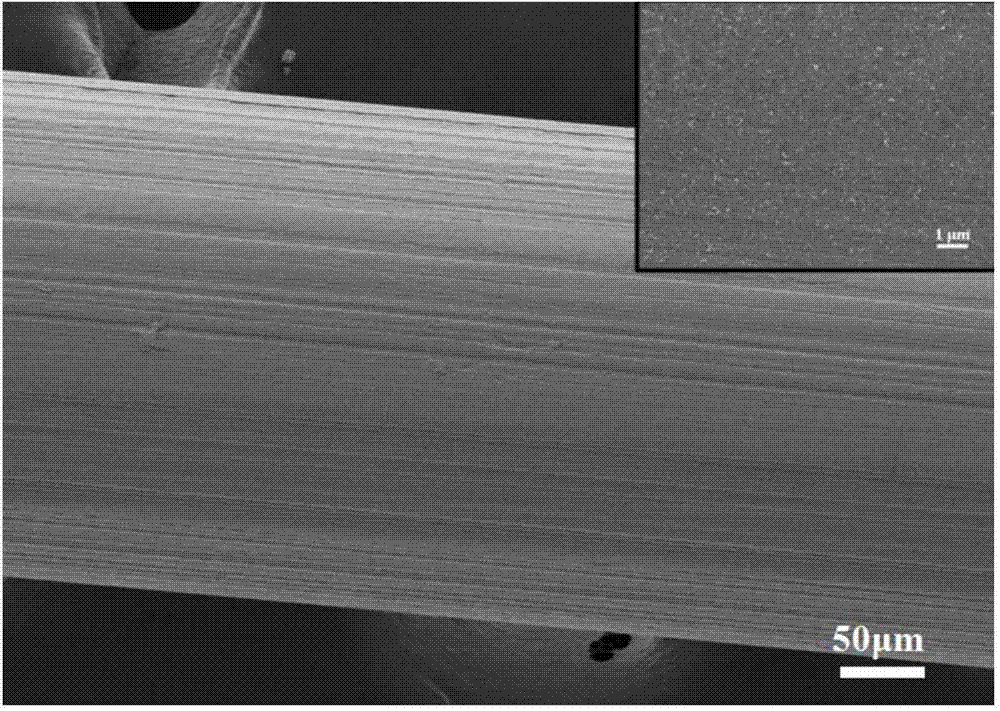

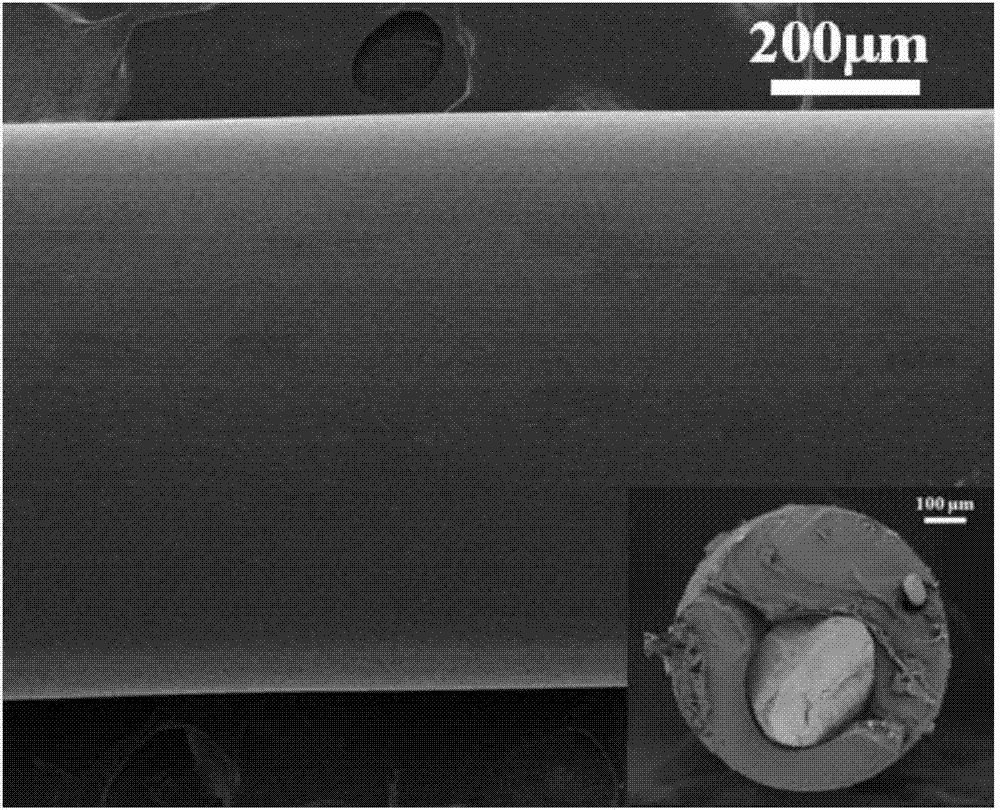

Embodiment 1

[0030] The stainless steel fibers were sequentially immersed in deionized water, acetone and ethanol for ultrasonic cleaning for 30 minutes, and dried for later use. Dissolve 0.850mL of 3,4-ethylenedioxythiophene monomer in 200mL of 0.1mol / L lithium perchlorate propylene carbonate solution to obtain a deposition solution, and put 0.3mm stainless steel fiber vertically into the deposition solution as a working electrode , with the platinum sheet as the counter electrode and Ag / AgCl as the reference electrode, under the conditions of constant voltage 1.3V and deposition time 8s, the stainless steel fiber with poly(3,4-ethylenedioxythiophene) deposited on the surface was obtained, and the obtained The stainless steel fiber deposited with poly(3,4-ethylenedioxythiophene) was dried under vacuum at 50° C. for 3 h. Lithium perchlorate, PMMA, propylene carbonate, and acetone were mixed at mass fractions of 3.70%, 11.5%, 42.4%, and 42.4%, respectively, and stirred to form a gel electro...

Embodiment 2

[0032] The stainless steel fibers were sequentially immersed in deionized water, acetone and ethanol for ultrasonic cleaning for 20 minutes respectively, and dried for later use. Dissolve 0.425mL of 3,4-ethylenedioxythiophene monomer in 200mL of 0.2mol / L lithium perchlorate propylene carbonate solution to obtain a deposition solution, and place a 0.1mm stainless steel fiber vertically into the deposition solution as a working electrode , with the platinum sheet as the counter electrode and Ag / AgCl as the reference electrode, under the conditions of constant voltage 1.4V and deposition time 6s, the stainless steel fiber with poly(3,4-ethylenedioxythiophene) deposited on the surface was obtained, and the obtained The stainless steel fiber deposited with poly(3,4-ethylenedioxythiophene) was dried at 70° C. for 0.5 h under vacuum condition. Lithium perchlorate, PMMA, propylene carbonate, and acetone were mixed according to the mass fraction of 2%, 13%, 40%, and 45%, respectively, ...

Embodiment 3

[0034]The stainless steel fibers were sequentially immersed in deionized water, acetone and ethanol for ultrasonic cleaning for 30 minutes, and dried for later use. Dissolve 0.850mL of 3,4-ethylenedioxythiophene monomer in 200mL of 0.3mol / L lithium perchlorate propylene carbonate solution to obtain a deposition solution, and put 0.3mm stainless steel fiber vertically into the deposition solution as a working electrode , with the platinum sheet as the counter electrode and Ag / AgCl as the reference electrode, under the conditions of constant voltage 1.3V and deposition time 15s, the stainless steel fiber with poly(3,4-ethylenedioxythiophene) deposited on the surface was obtained, and the obtained The stainless steel fiber deposited with poly(3,4-ethylenedioxythiophene) was dried at 30° C. for 4 h under vacuum condition. Lithium perchlorate, PMMA, propylene carbonate, and acetone were mixed according to the mass fraction of 5%, 10%, 45%, and 40%, respectively, and stirred to form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com