Automatic intermittent coal bed gas draining and generating method and device thereof

A technology for coalbed methane and gas devices, which is applied to drainage, safety devices, components of pumping devices for elastic fluids, etc. The electric effect is remarkable, the workload is reduced, and the output is increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

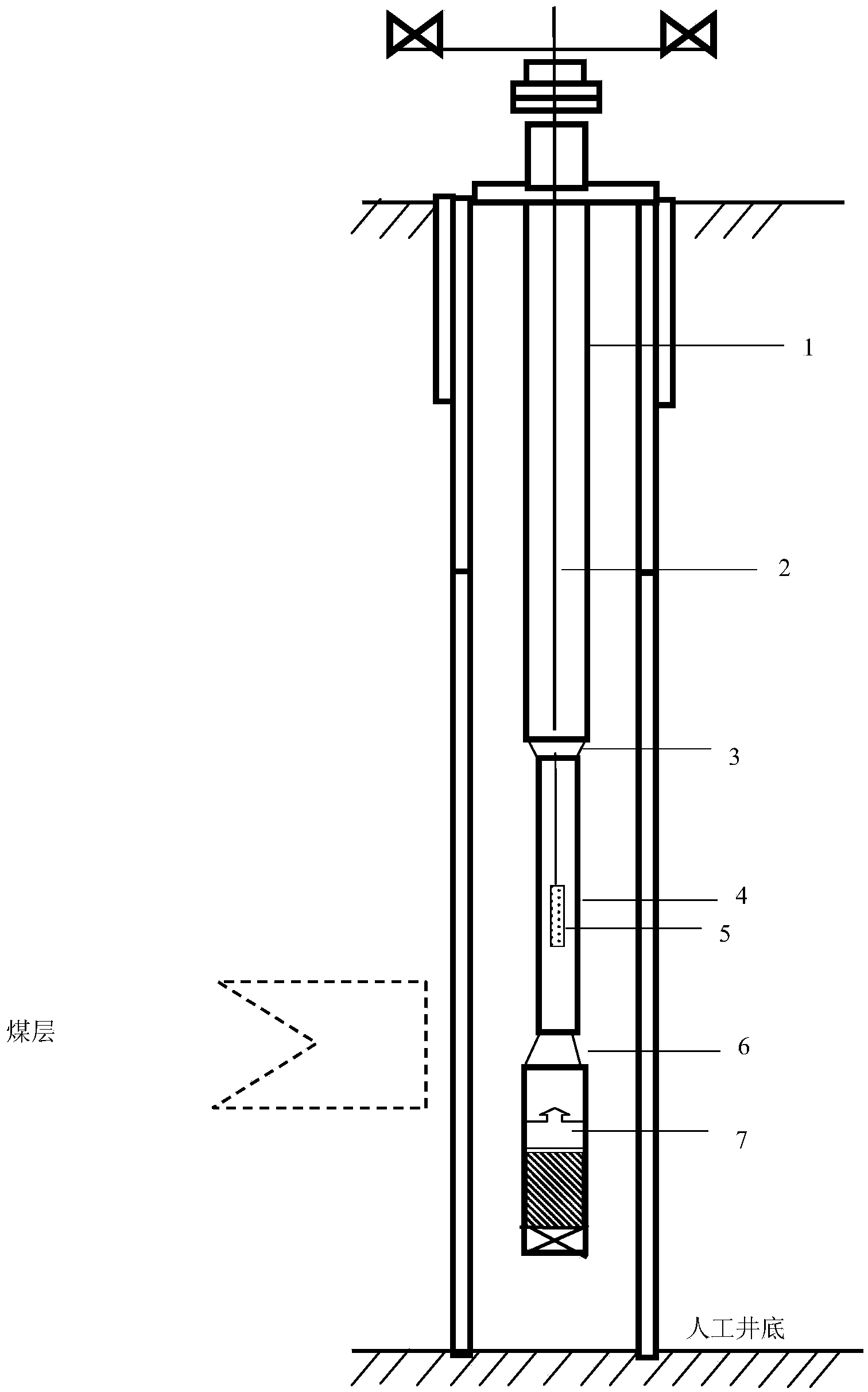

[0035](1) The forward rotation of the reciprocating driving device drives the flexible rod 2 and the elastic piston to descend in the pump cylinder. At this time, the valve ball of the valve 7 is seated on the valve seat, and the valve is closed to pass through the casing, the screen tube and the valve in turn. Valve 7 enters the oil pipe 1 and the water in the pump barrel is enclosed in the oil pipe;

[0036] (2) When the elastic piston reaches the lower buckle 6, the reciprocating driving device stops, and then the reciprocating driving device reverses and drives the flexible rod 2, and the flexible rod 2 drives the elastic piston 5 upward to push out the water in the pump cylinder. At this time, the elastic piston A vacuum is formed between 5 and Vail 7. Due to the action of water pressure, Vail ball is washed up by water, the water is perforated into the casing by the casing, and then enters the oil pipe 1 through the screen pipe and Vail 7;

[0037] (3) Repeat steps (1) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com