X-ray electronic device detection system

A technology for optoelectronic devices and detection systems, applied in the field of X-ray detection systems, can solve the problems of no joystick, no additional two-dimensional mobile worktable movement limit, etc., to reduce radiation, avoid misjudgment, and reduce operation risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

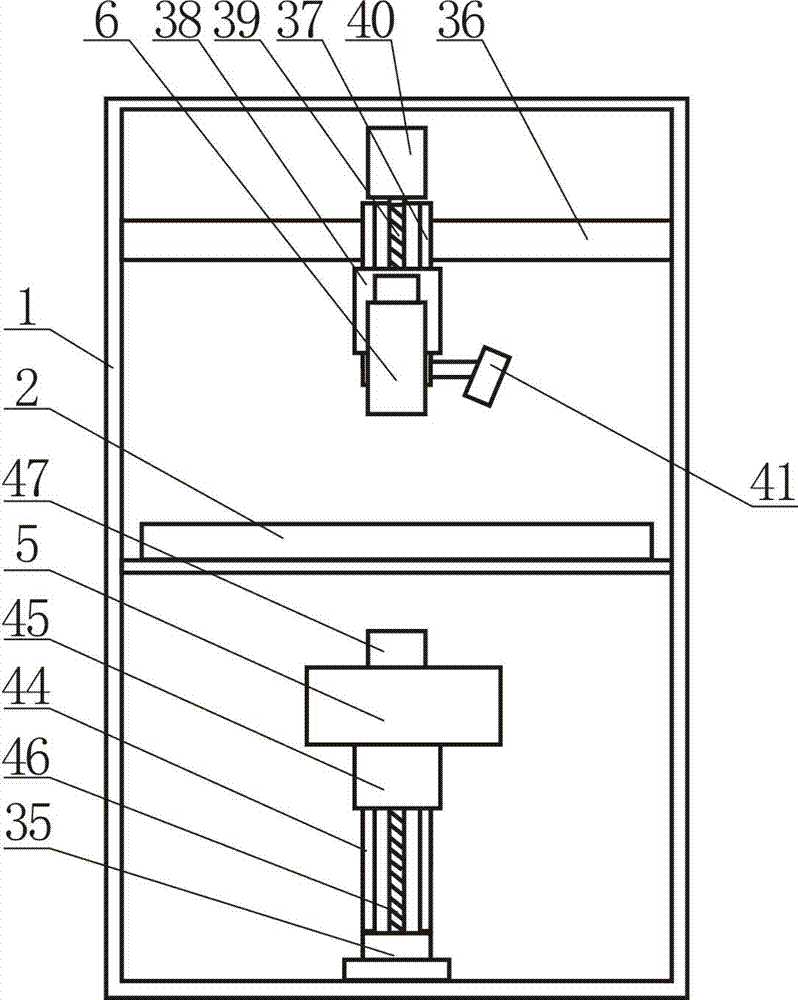

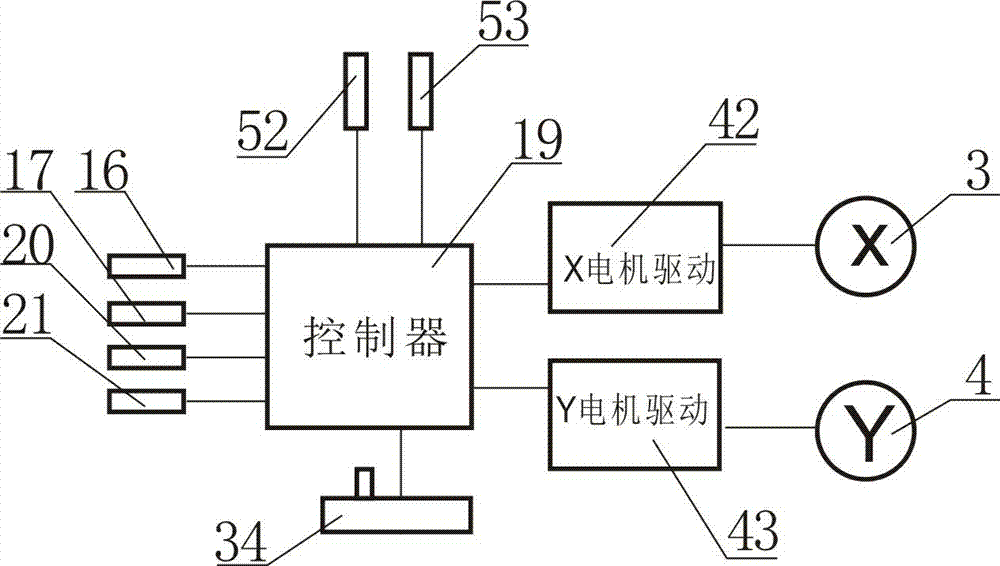

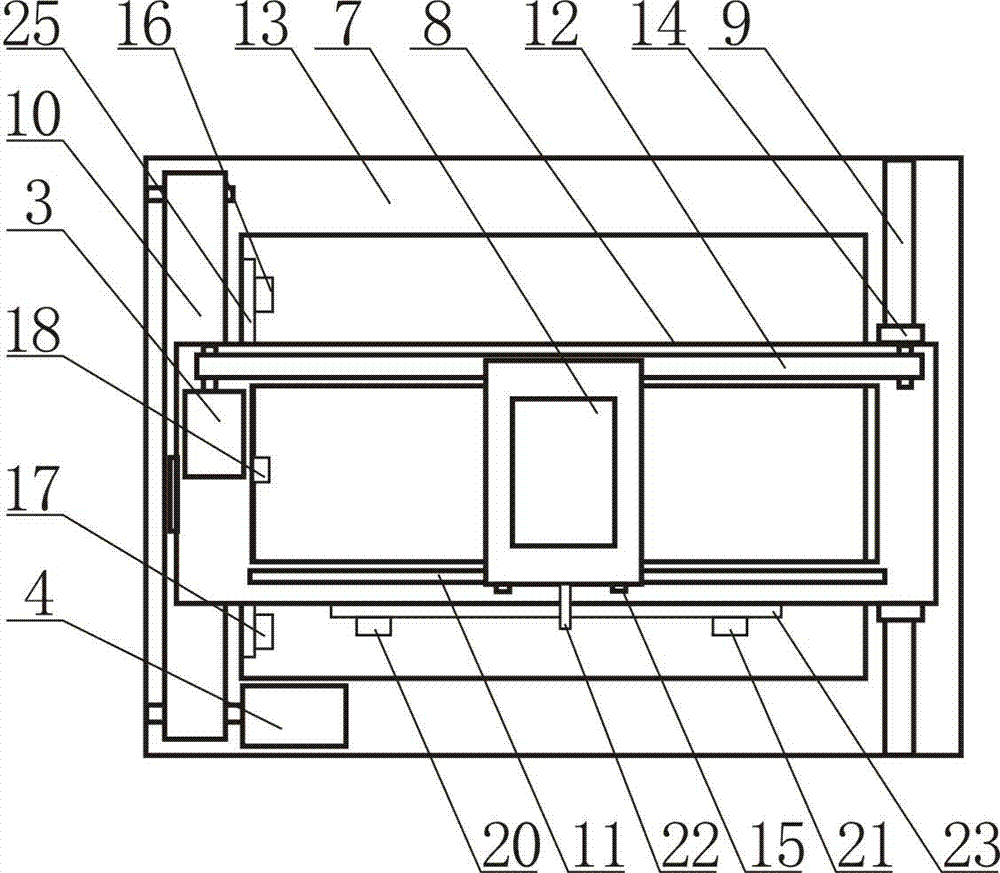

[0034] Such as figure 1 , 2 As shown, the X-photoelectronic device detection system includes a chassis 1, a two-dimensional mobile worktable 2 arranged in the chassis 1, an X-axis stepping motor 3 and a Y-axis stepping motor 4 that drive the two-dimensional mobile worktable 2 to move, and the design The X-ray generator 5 below the two-dimensional mobile workbench 2 is arranged on the X-ray image intensifier 6 above the two-dimensional mobile workbench 2, and a beam is arranged in the cabinet 1 and above the two-dimensional mobile workbench 2 36, the beam 36 is provided with a vertically arranged slide rail 37 and a slide seat 38 on the slide rail 37, the slide rail 37 is provided with a lead screw 39 threaded with the slide seat 38, and the slide rail The upper end of 37 is provided with servo motor 40, and described servo motor 40 is connected with the upper end of lead screw 39, and described X-ray image intensifier 6 is fixed on the sliding seat 38, and one side of describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com