Multi-core optical fiber, sensing device with same and operating method of sensing device

A technology of multi-core optical fiber and sensing device, which is applied in the direction of multi-core optical fiber, the use of optical devices to transmit sensing components, multi-layer core/clad optical fibers, etc. Solve problems such as single test parameters to achieve the effect of eliminating fluctuations in optical power, good market prospects, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

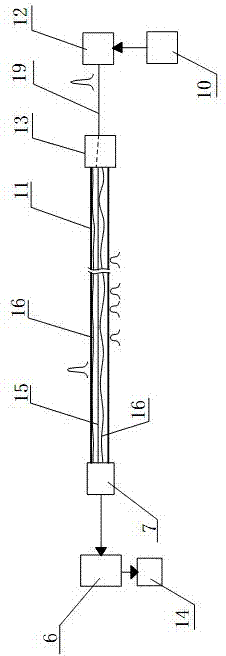

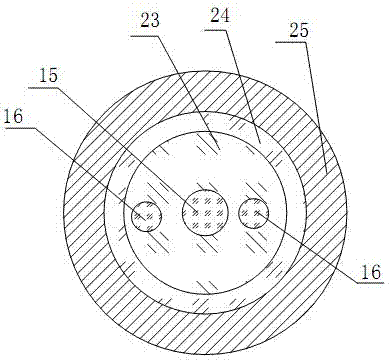

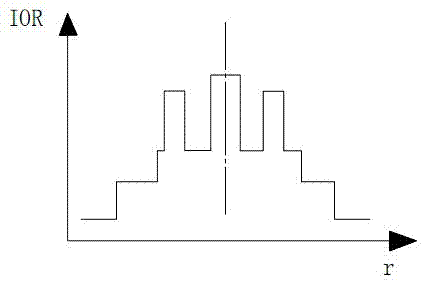

[0053] like figure 1 , figure 2 , image 3 and Figure 4 Shown is a multi-core optical fiber and an optical fiber sensing device based on the multi-core optical fiber. The optical fiber sensing device includes a control module 10, a light source module 12, a coupling module-13, a photodetector module-7 and a processing module 6, and the control module 10 is connected to the light source module 12 and controls the latter to send an optical signal, preferably a pulsed light signal, the light source module 12 is connected to the coupling module one 13 through an auxiliary optical fiber 19, and the coupling module one 13 is connected to one end of the multi-core optical fiber 11 connection, the multi-core optical fiber 11 has at least three cores arranged in the inner cladding 23, one of which is the transmission core 15, and the other cores are the sensing core 16, at least one sensing core 16 The length is different from the length of the transmission core 15; the coupling m...

Embodiment 2

[0072] like Figure 6 A kind of optical fiber sensing device shown, differs from embodiment 1 in that the other end of the multi-core optical fiber 11 is connected to the coupling module 3 4, the coupling module 3 4 includes three channels, and each channel is connected to each other. There is no interference, at least two sensing cores 16 and transmission cores 15 in the multi-core optical fiber 11 are respectively connected to three channels, and are respectively connected with the optical detector module 17 and the optical detection module 1 through the coupling module 3 4 The sensor module two 8 is connected to the photodetector module three 5; the photodetector module one 7, the photodetector module two 8 and the photodetector module three 5 are connected to the processing module 6.

[0073] The operation steps of the program are as follows:

[0074] 1) Including the sensing fiber 11, the transmission fiber core 15 and the sensing fiber core 16 contained in it have diffe...

Embodiment 3

[0080] like Figure 7 As shown, the difference between this embodiment and Embodiment 1 is: an optical fiber sensing device based on a multi-core optical fiber 11, including a control module 10, a light source module 12, a coupling module-13, an optical detector module-7 and a processing module 6. The control module 10 is connected to the light source module 12 and controls the latter to send out optical signals. The light source module 12 is connected to the coupling module one 13, and the coupling module one 13 is connected to one end of the multi-core optical fiber 11. The multi-core optical fiber 11 is that at least three fiber cores are arranged in the inner cladding 23, wherein one fiber core is the transmission fiber core 15, and the other fiber cores are the sensing fiber core 16, and the length of at least one sensing fiber core 16 is the same as that of the transmission fiber core 15. The lengths are different; the coupling module one 13 has at least two channels, ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com