Dry constant temperature test chamber

A constant temperature test and drying technology, which is applied in the direction of laboratory appliances, heating or cooling equipment, shells or chambers, etc., can solve the problems that the constant temperature incubator cannot be controlled with high precision constant temperature, achieve stable temperature rise, realize temperature, and slow down the airflow velocity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

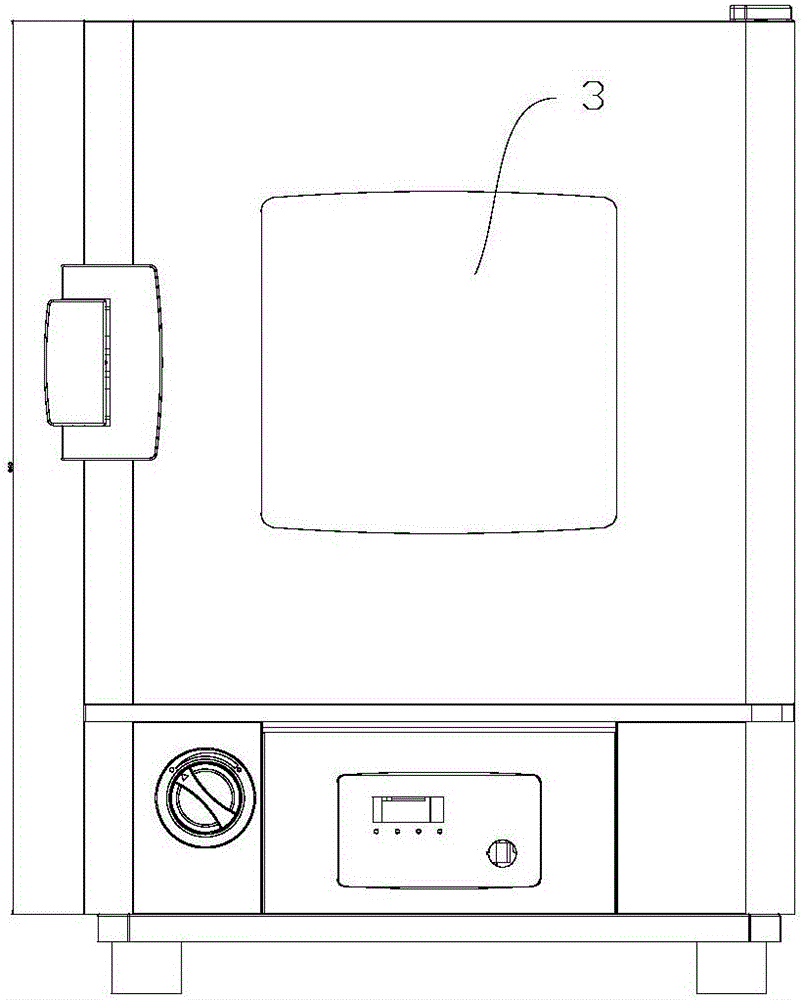

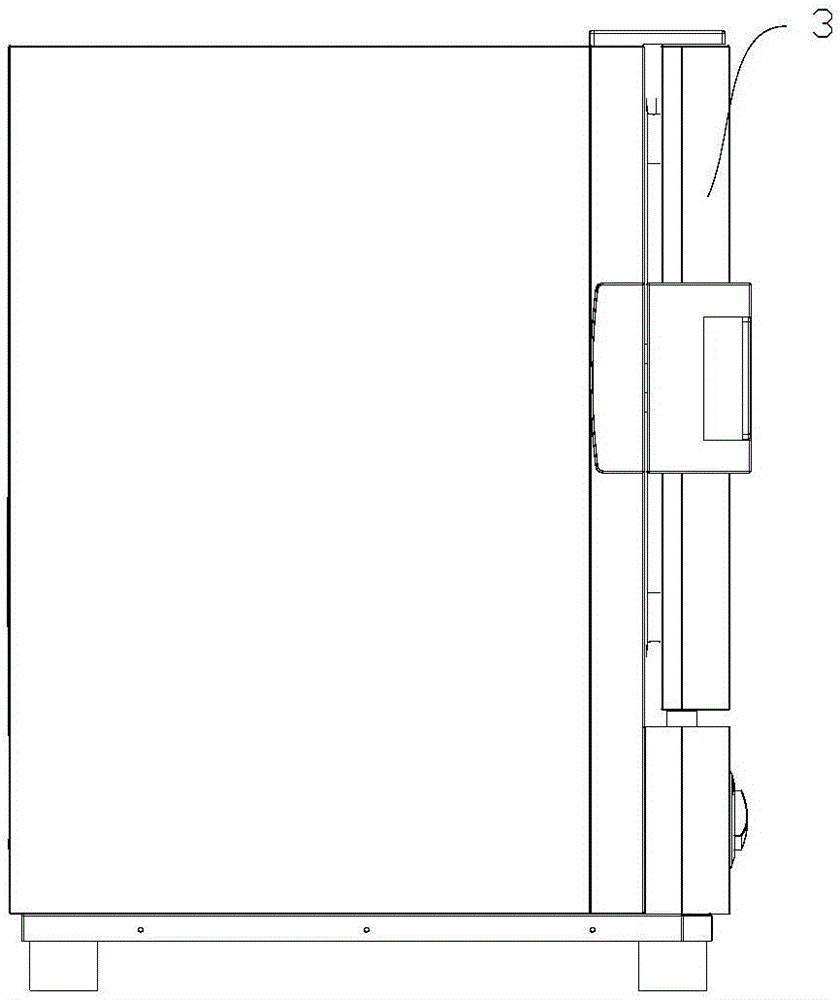

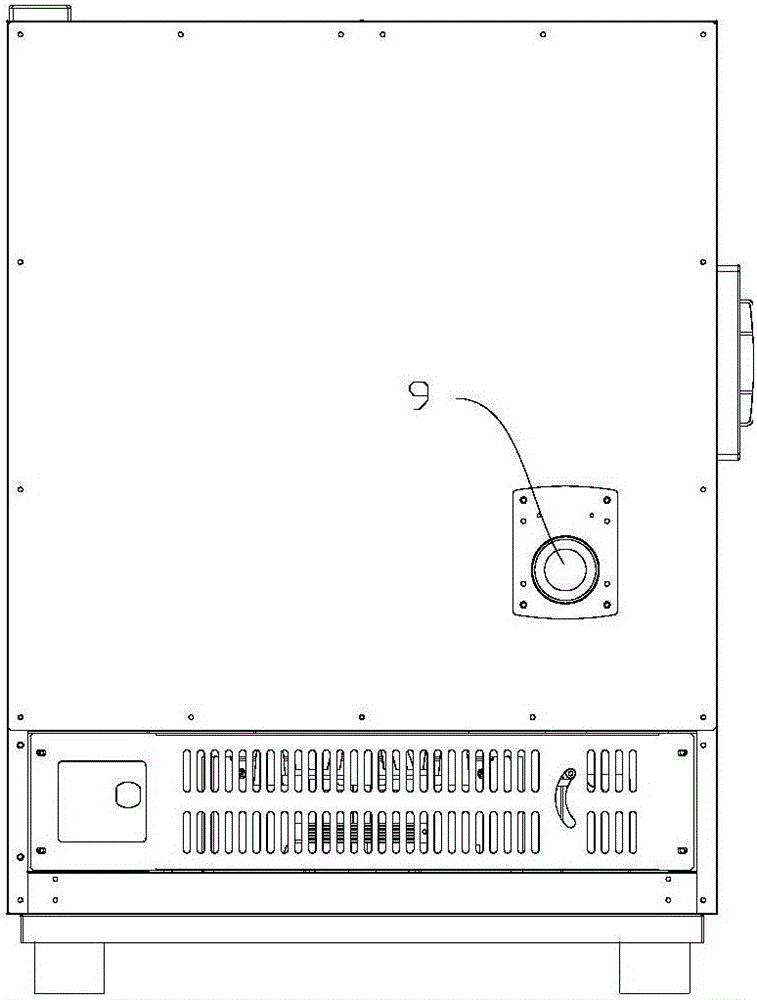

[0029] Dry constant temperature test chamber, such as Figure 1-5 As shown, including the insulation layer 1, the constant temperature air circulation device 2, and the front door 3, the insulation layer 1 and the front door 3 form a closed constant temperature inner chamber 4. In order to improve the strength of the constant temperature inner cavity 4, the upper, lower, left, and right side walls of the constant temperature inner cavity 4 (wherein the inner side wall refers to the side wall relative to the front door 3, and the upper and lower side walls refer to the side wall relative to the front door 3). The side walls on both sides in the vertical direction, the left and right side walls refer to the side walls on both sides in the horizontal direction relative to the front door 3) respectively covered with metal plates 41, which can usually be made of materials such as copper, aluminum alloy, steel, etc. , the junction of the right and inner side walls and the lower side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com