Double-wire arc welding power system based on sinusoidal wave modulating pulses

A technology of sine wave modulation and power supply system, which is applied to arc welding equipment, manufacturing tools, welding equipment, etc., and can solve problems such as lack of system theory regularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be further described below in conjunction with specific examples.

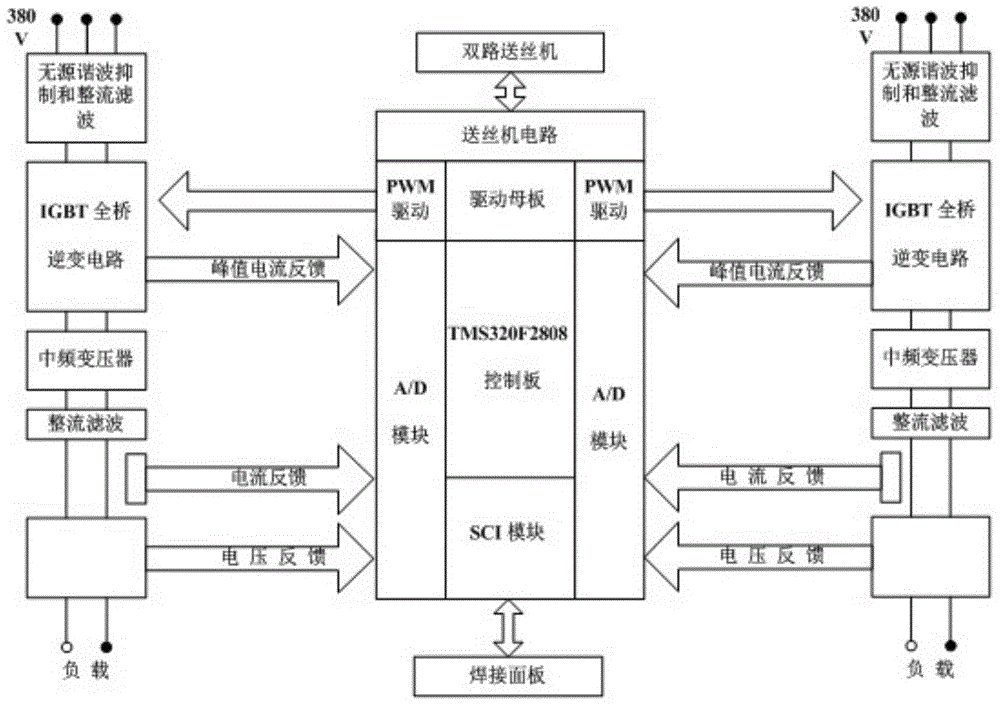

[0076] The twin-wire arc welding power supply system based on sine wave modulation pulse described in this embodiment includes:

[0077] Mathematical model for sine wave modulation pulse, used to convert the welding pulse current I i The peak value and base value of the value change according to the law of sine waves, forming the peak value and base value current sequence value;

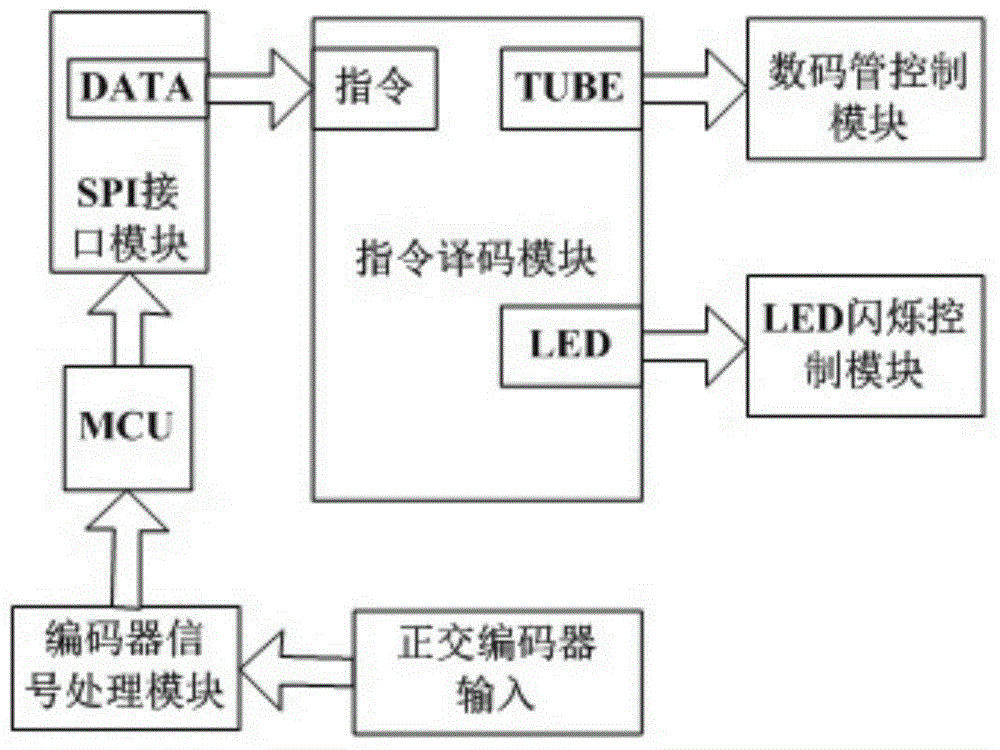

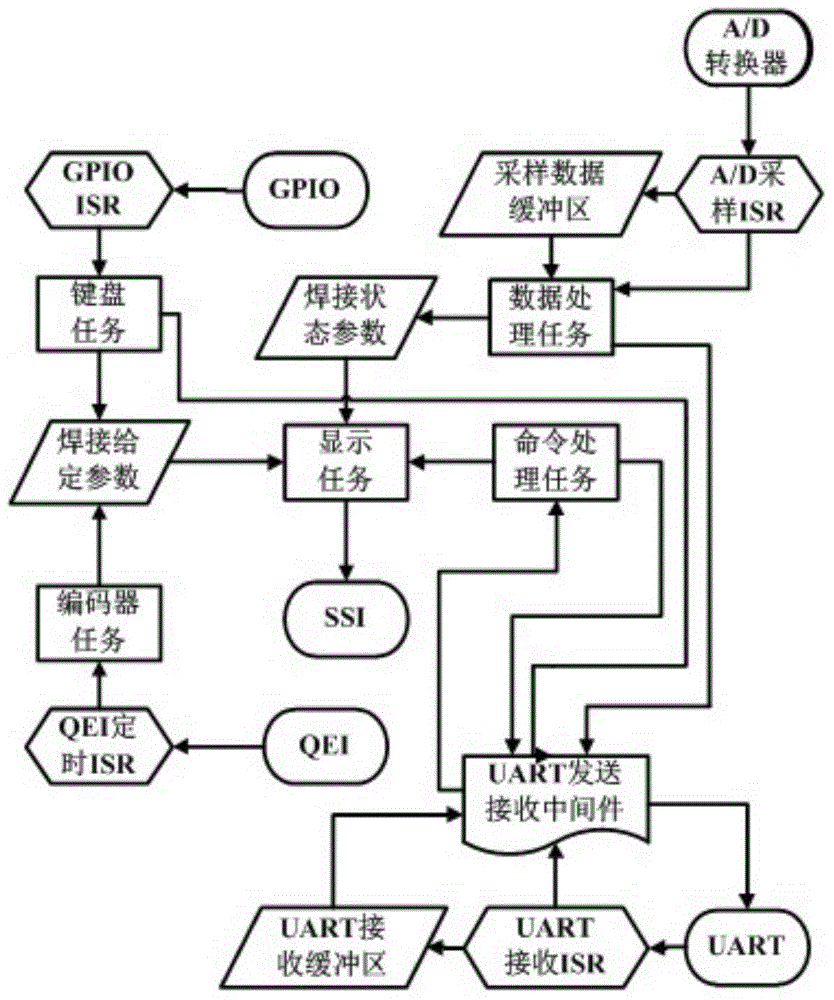

[0078] The control detection circuit with DSP as the control core is used to realize the closed-loop control of the twin-wire arc welding power supply system to ensure that the output current and voltage of the system have a stable closed-loop controllability. The DSP is used for flexible programming to realize the digitalization of the control process of the system. At the same time, on the basis of the above mathematical model, the sine wave modulation pulse technology is realized, so that the wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com