Catalytic Partial Oxidation of Natural Gas and Carbon Dioxide Mixture to Syngas

A gas catalytic part, carbon dioxide technology, applied in inorganic chemistry, chemical instruments and methods, non-metallic elements, etc., can solve the problems of not meeting the hydrogen-carbon ratio requirements of oxo synthesis gas and the high ratio of synthesis gas, and achieve easy large-scale, low-cost Simple effect of installation investment and process setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

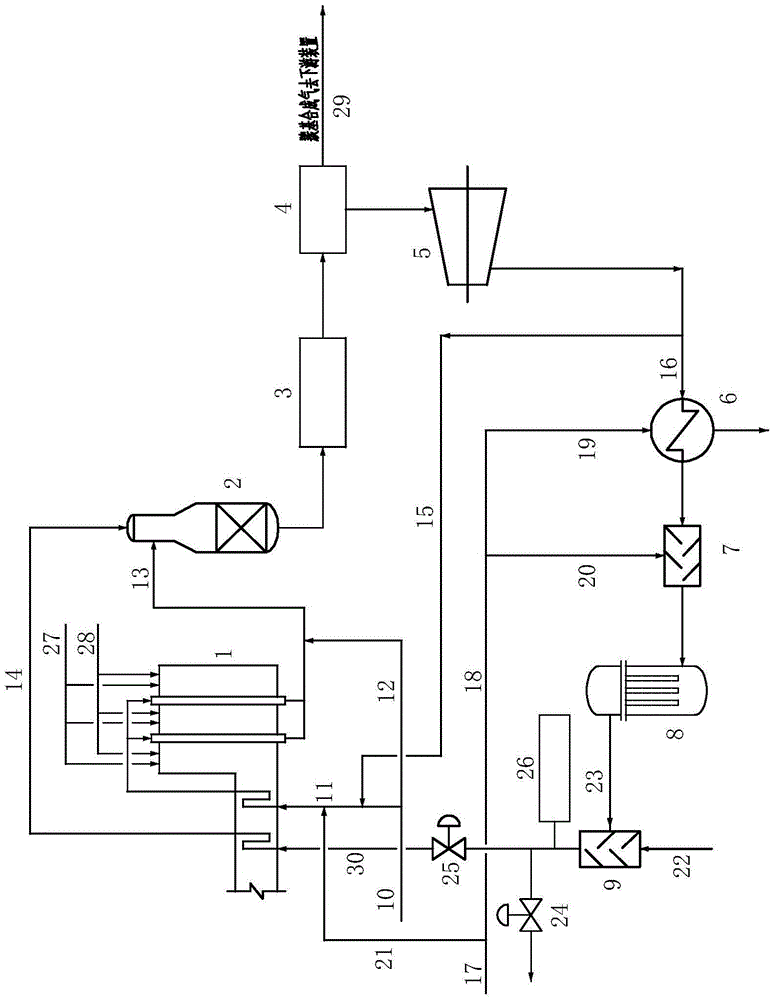

[0048] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0049] Such as figure 1 As shown, the process of catalytic partial oxidation of natural gas and carbon dioxide mixed gas to synthesis gas includes a top-fired square box-type primary reformer 1, a pure oxygen secondary reformer 2, a set of cooling liquid separation system 3, a set of degassing Carbon system 4, a CO 2 Compressor 5, a CO 2 Heater 6, a precision filter 8 and CO 2 , steam and O 2 Mixer 7,9.

[0050] Such as figure 1 As shown, the natural gas 10 from the hydrodesulfurization unit at a temperature of 370°C is divided into two streams, the first stream of natural gas 11 is natural gas 11 with a flow rate of about 75% of the total flow, and is mixed with medium-pressure steam 21 from the boundary zone at a temperature of 330°C , the water-to-carbon ratio is 3.2, and the pipeline 15 is used to make up the CO 2 The first stream o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com