An intelligent alum mixing and feeding method and an algorithm for mixing alum concentration and liquid level

An intelligent algorithm and alum-distributing technology, applied in sequence/logic controller program control, flocculation/sedimentation water/sewage treatment, electrical program control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

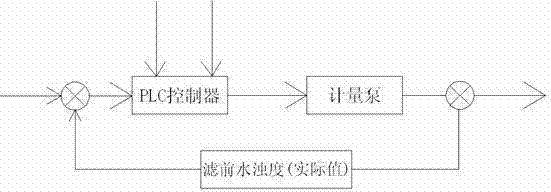

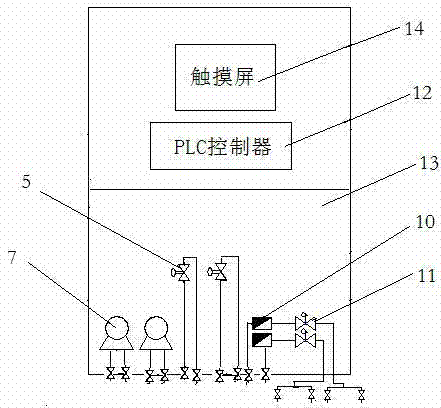

[0077] The present invention is based on the experience database and intelligent algorithm of the intelligent alum distributing and feeding system, the PLC is the control core component, the industrial computer or the touch screen is used as the man-machine interface device, and alum is mixed and fed in combination with system equipment such as distributing alum and feeding alum.

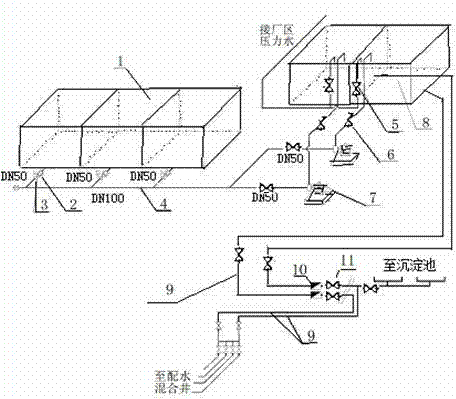

[0078] Such as figure 2 As shown, the intelligent alum distribution system includes PLC controller, raw alum tank 1, electric valve 2, manual maintenance valve 3, raw alum pipe 4, water adding solenoid valve 5, check valve 6, raw alum pump 7, high alum Pool 8, alum outlet pipe 9, electromagnetic flowmeter 10, automatic regulating valve 11, mixer, water inlet pipe, raw alum pool level gauge, high level alum pool level gauge, source water flow meter, source water turbidity meter, source water sampling tube. (Some equipment is not shown in the figure)

[0079] Connect the raw alum tank, electric val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com