High-performance online pipeline plugging device and plugging method thereof

A plugging device and high-performance technology, applied in the direction of pipes, pipe components, branch pipelines, etc., can solve the problems of temporary backfilling on the ground, affecting the normal life of urban traffic, and medium leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] High-performance non-stop pipeline sealing and sealing method, the specific sealing steps are as follows:

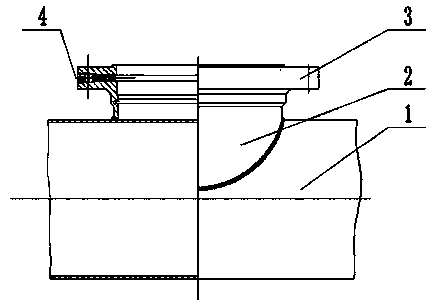

[0078] 1) Welding steps between the pipe interface device and the pipe, such as image 3 As shown, the saddle-shaped pipe joint is placed on the steel pipe that needs to be opened, and the saddle-shaped pipe joint and the pipe are welded together by electric welding along the edge of the saddle-shaped pipe joint and the outer wall of the pipe, and the weld is inspected according to the specifications. , proceed to the next step of connecting the pipeline process valve device and the pipeline interface device;

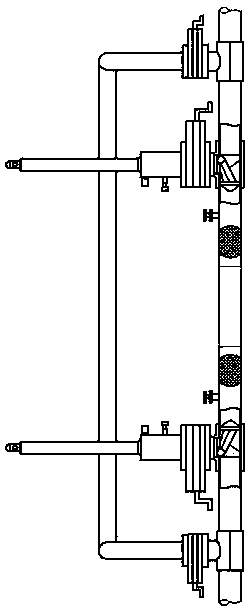

[0079] 2) The connection steps between the pipeline process valve device and the pipeline interface device, such as Figure 4 As shown, the gate valve of the pipeline process valve device and the flange on the upper part of the pipeline interface device are sealed together with bolts, and the installation of the pipeline opening device and the pipeline ope...

Embodiment 2

[0091] The problem to be solved by the present invention is: to provide a high-performance non-stop pipeline inner wall cleaning device, which can clean up the remaining open iron filings and sealing position sundries on the pipeline inner wall; to provide a high-performance non-stop pipeline plugging device , can make the seal achieve controllable expansion, and achieve the purpose of the seal and the inner wall of the pipeline closely fitting, especially suitable for high pressure and spiral welded pipeline sealing, practical

[0092] The sealing effect of zero leakage is now achieved.

[0093] The specific working structure and principle are as follows:

[0094] 1 High-performance non-stop pipeline inner wall cleaning device

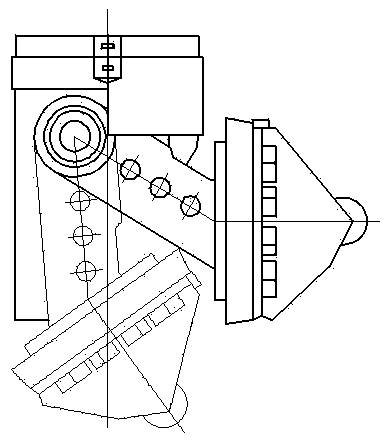

[0095] 1.1 Cleaning device for iron filings left at the pipe opening (such as Figure 6 shown)

[0096] 1.1.1 Structure

[0097] It is composed of a box body 9, an observation window 10, an adjustable spherical sealing joint 11, a control rod 12 and...

Embodiment 3

[0122] The conical pressure plate of the present invention can adopt the above-mentioned hydraulic drive mode or mechanical transmission mode, such as: worm gear drive, gear drive, screw drive, cam drive, etc. to drive the conical pressure plate to extrude the sealing ring to expand, Realize the sealing of the pipeline under pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com