Seal valve material returning system for chemical loop combustion system

A technology of chemical chain combustion and sealing valve, which is applied in the direction of burning fuel in the melting state, fluidized bed combustion equipment, combustion method, etc., can solve the problems of artificial control of material flow, poor material flow and unstable operation , to achieve the effect of simple structure, convenient manufacturing and installation, improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

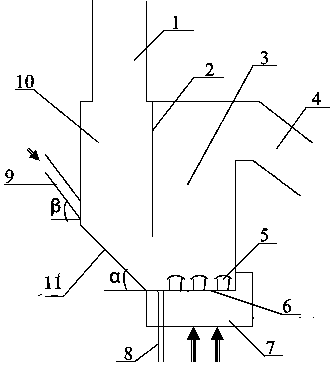

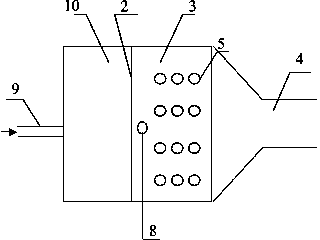

[0023] Depend on figure 1 , figure 2 As shown, the present invention mainly consists of a moving bed 10, a fluidized bed 3, a return pipe 4, a horizontal air distribution plate 6, an inclined air distribution plate 11, an air chamber 7 and an air cap 5. The effective area of the moving bed 10 is smaller than the effective area of the fluidized bed 3 (the effective area here refers to the projected area of the moving bed and the fluidized bed on the horizontal plane). The horizontal air distribution plate 6 bears the weight of the whole device. The moving bed 10 and the fluidized bed 3 are separated by heat-resistant steel partitions 2. The partitions 2 are welded on both side walls, and the upper end is welded into the refractory layer on the top surface. Partition 2 is sealed with the welds on both side walls and the top surface, and a certain distance is le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com