LED lighting product accelerated attenuation test method based on multilevel stepping stress

A technology of LED lighting and step stress, which is applied in the direction of testing optical properties, etc., can solve the problems that the accuracy cannot be further improved, the accuracy of product life prediction is low, and the test data extrapolates product life information, etc., to shorten the accelerated test evaluation cycle time, improved flexibility and versatility, and reduced test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

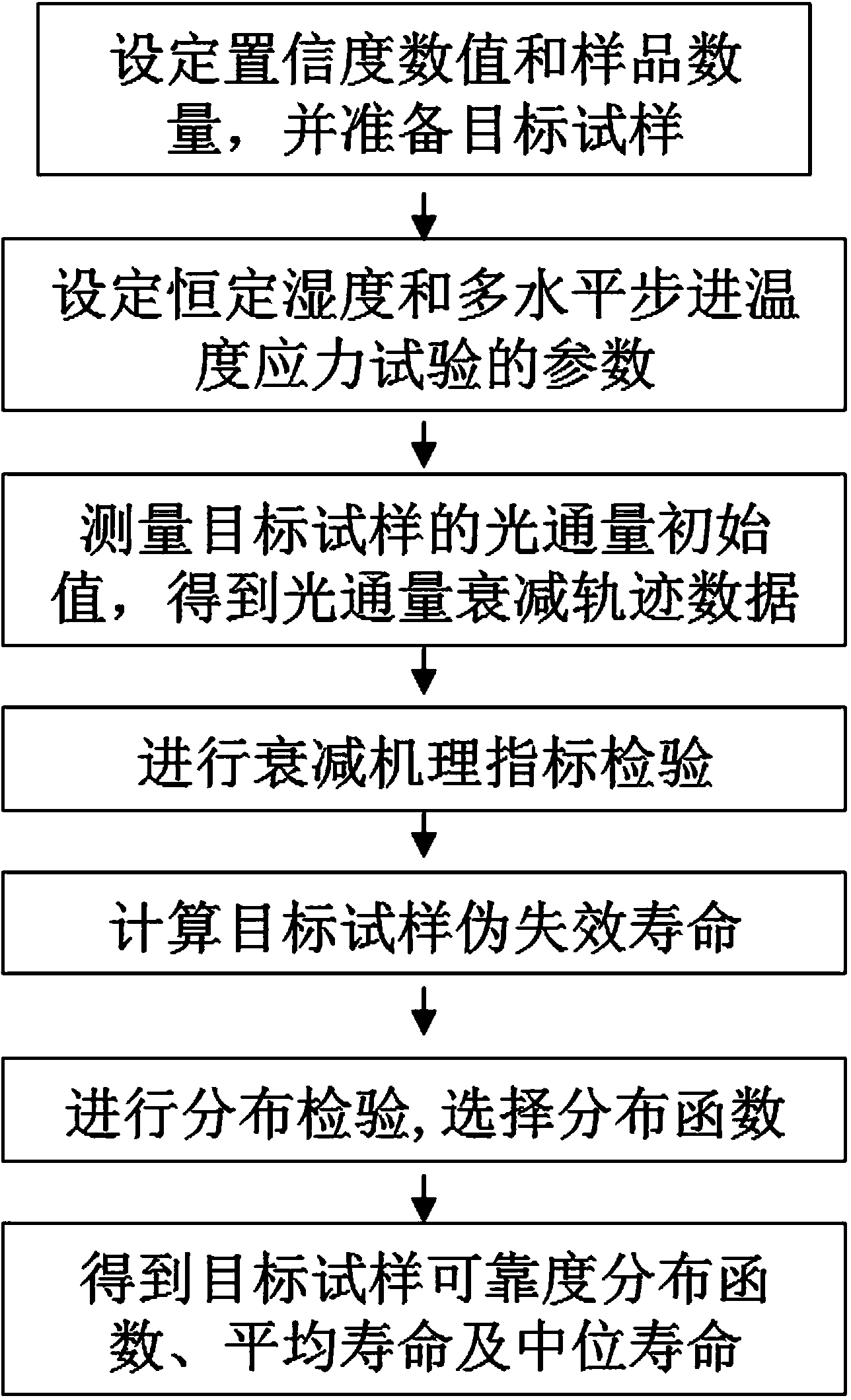

[0037] refer to Figure 1-Figure 9 : The method for accelerated decay test of LED lighting products based on multi-level step stress, including the following steps:

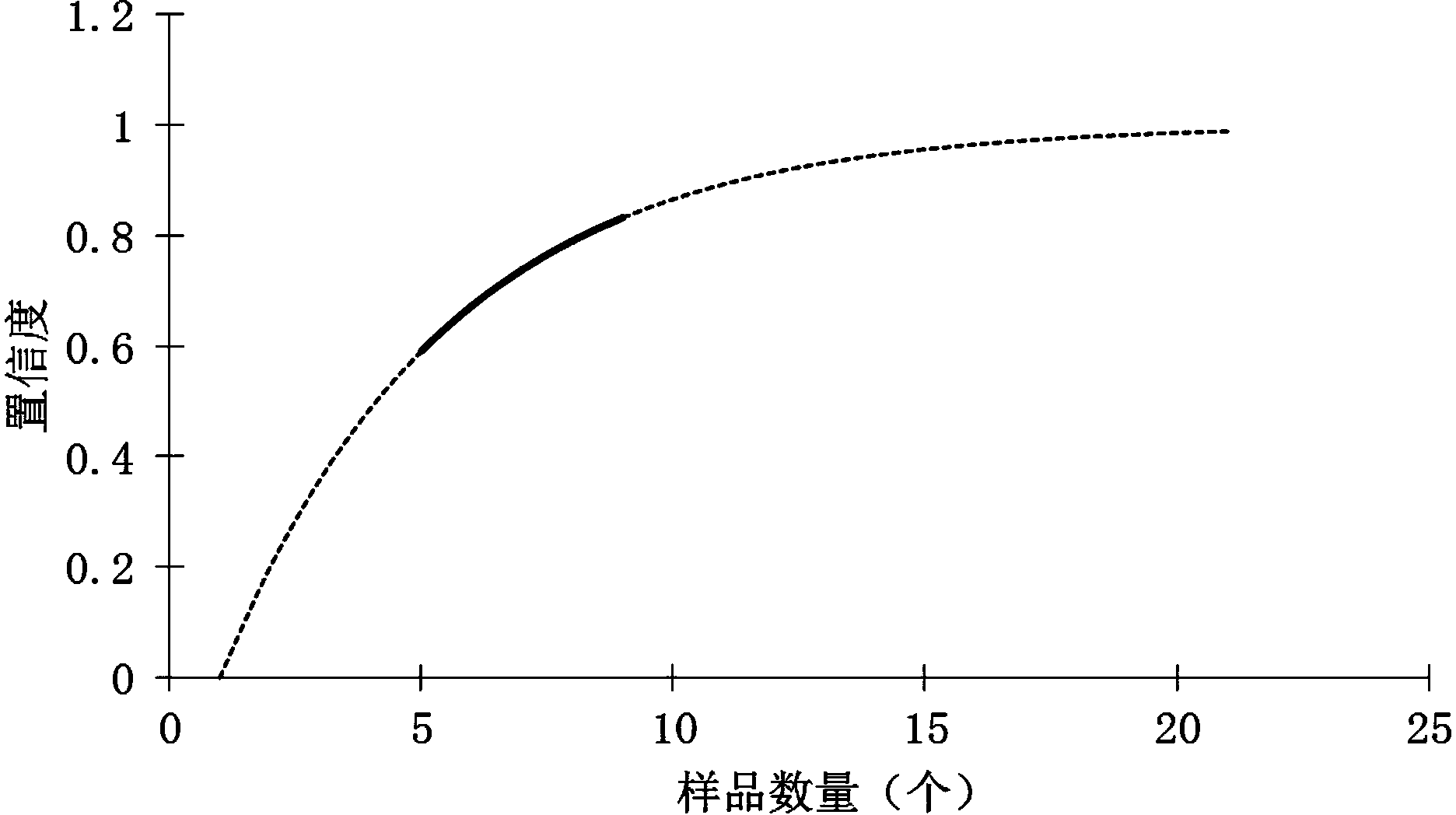

[0038] 1) Set the confidence level P a Value and sample number n, and prepare the target sample;

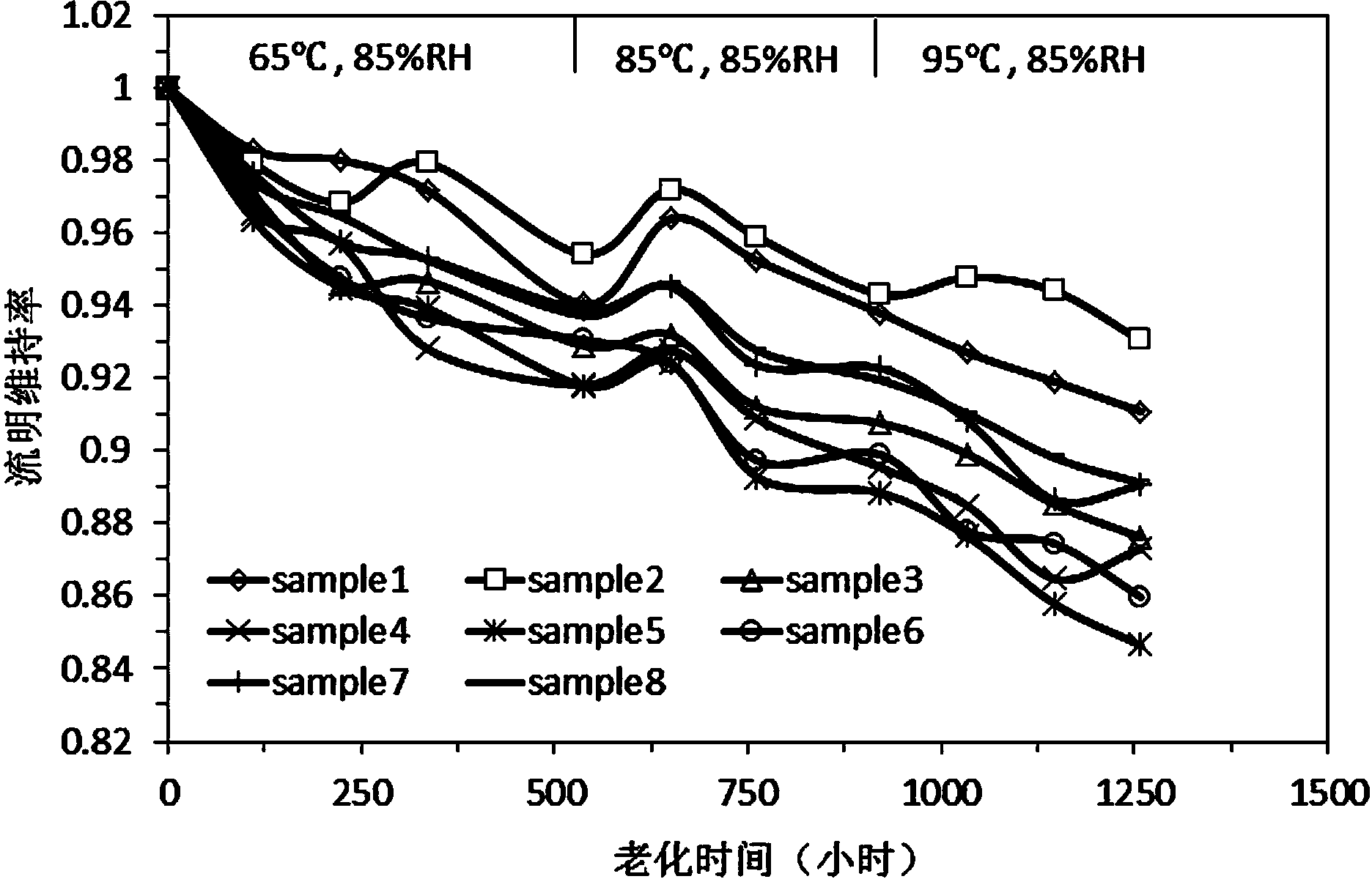

[0039] 2) Based on the highest nominal ambient temperature of the product, set the constant humidity stress and multiple step temperature stress levels and the total test time, and set the step time and measurement time nodes of each temperature stress;

[0040] 3) Measure the initial value of the luminous flux of the target sample, and obtain the luminous flux attenuation trajectory data of the target sample under the environment of constant humidity stress and multi-level step temperature stress level;

[0041] 4) Use the composite exponential decay trajectory model to fit the performance decay data under various temperature stresses, and carry out the decay mechanism index inspection at each stress level;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com