Method for determining structure of cobalt phase in WC-Co cemented carbide

A technology of cemented carbide and cobalt phase, which is applied in the field of determining the structure of cobalt phase in WC-Co cemented carbide, can solve the problems of difficulty in EBSD, difficulty in accurately determining cobalt phase, and inability to correctly guide production, etc. method reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Grind the WC-Co cemented carbide on a 300-mesh diamond surface grinder for 5mins, cool with an oil-water mixture; grind the sample on a 1800-mesh diamond grinding wheel for 8mins, water-cooled; use 15 micron diamond polishing paste, polish the sample on nylon cloth for 20mins ; Finally, 1 micron diamond is used to polish the sample on the flannelette for 5mins to obtain a smooth surface of the cemented carbide sample.

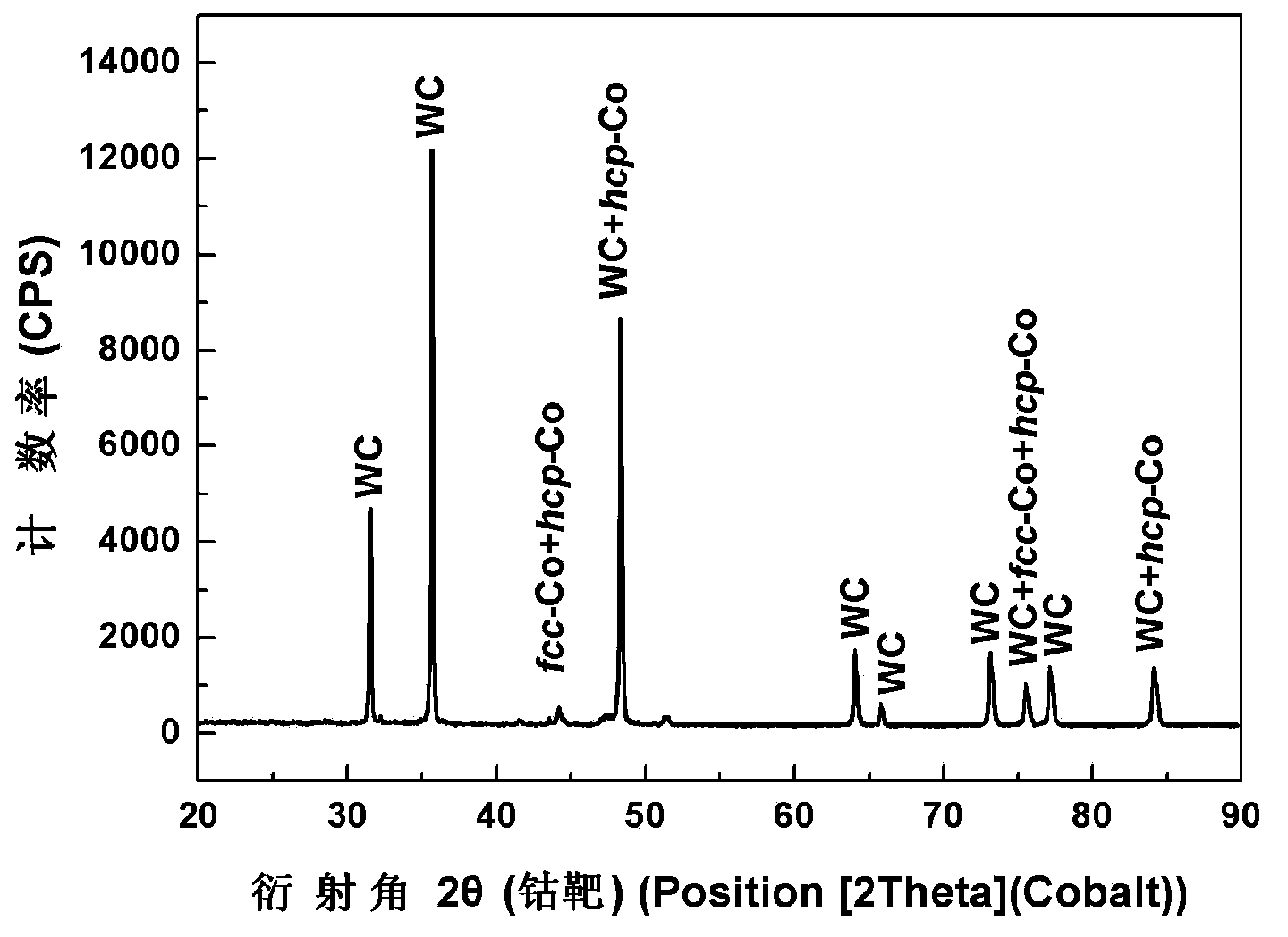

[0051] The structure of the cobalt phase in the WC-Co cemented carbide samples without electrolytic WC was tested on an XRD analyzer. The test parameters are: voltage 40kV, beam current 40mA, step size 0.033°, dwell time for each step 10s, Co target The XRD pattern of the WC-Co cemented carbide without electrolytic WC is shown in Figure 4 .

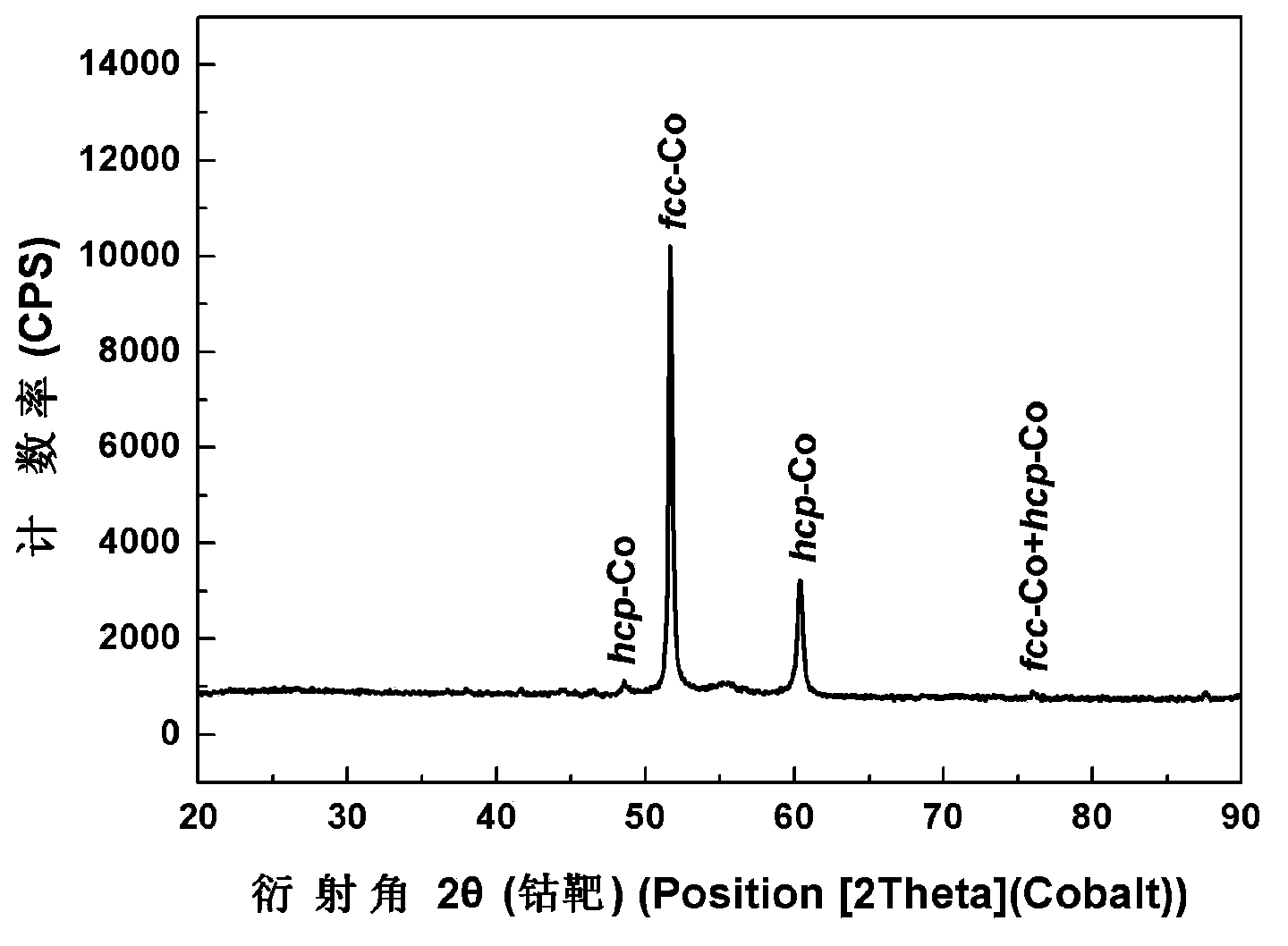

[0052] Place the above-mentioned cemented carbide sample with a flat cemented carbide sample surface in 4mol / LNaOH, 0.33mol / L C under 4.5V DC voltage 4 h 6 O and 0.09mol / L HClO 4 After electrolysis of the mix...

Embodiment 2

[0056] The cobalt phase composition and structural changes of the coarse-grained WC-Co cemented carbide during compression were analyzed, and the coercive force of the WC-Co cemented carbide before compression was determined to be 41.6Oe.

[0057] Grind the cemented carbide sample on a 300-mesh diamond surface grinder for 5 minutes, and cool it with an oil-water mixture; grind the sample on a 1800-mesh diamond grinding wheel for 10 minutes, and water-cool; use 15 micron diamond polishing paste, and polish the sample on nylon cloth for 20 minutes; Finally, 1 micron diamond is used to polish the sample on the flannelette for 5mins to obtain a smooth surface of the cemented carbide sample.

[0058] The WC grains on the surface of the sample were removed by electrolysis, and a sample with a surface layer of 80-100 μm without WC grains was prepared. The electrolysis conditions are: DC voltage is 6V, electrolytic solution is 3.5mol / L KOH, 0.24mol / L C 4 h 6 O and 0.05mol / L HClO 4 ...

Embodiment 3

[0069] The change of cobalt phase grain size during the compression process of coarse-grained WC-Co cemented carbide was analyzed.

[0070] Grind the cemented carbide sample on a 300-mesh diamond surface grinder for 5 minutes, and cool it with an oil-water mixture; grind the sample on a 1800-mesh diamond grinding wheel for 10 minutes, and water-cool; use 15 micron diamond polishing paste, and polish the sample on nylon cloth for 20 minutes; Finally, 1 micron diamond is used to polish the sample on the flannelette for 10 mins to obtain a smooth surface of the cemented carbide sample.

[0071] The WC grains on the surface of the sample were removed by electrolysis, and a sample with a surface layer of 80-100 μm without WC grains was prepared. The electrolysis conditions are: DC voltage is 6V, electrolytic solution is 3.5mol / L KOH, 0.24mol / L C 4 h 6 O and 0.05mol / L HClO 4 The mixed solution, the electrolysis time is 10h, and the alloy sample is used as the anode. After the el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coercive force | aaaaa | aaaaa |

| Coercive force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com