Adjustable fluidized bed coating process and adjustable fluidized bed coating device

A coating and flow adjustment technology, applied in the direction of powder suspension granulation, etc., can solve the problems of difficult quality assurance, unqualified quality, increased adhesion rate, etc., and achieve the effects of low production cost, high product quality, and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further described by taking the production of a kind of lysine hydrochloride concentrated liquid pure product as raw material, and the rumen-passing protection product whose weight of rumen-passing fat powder accounts for 50% as an example to further illustrate the present invention, but the description does not constitute any limitation of the present invention .

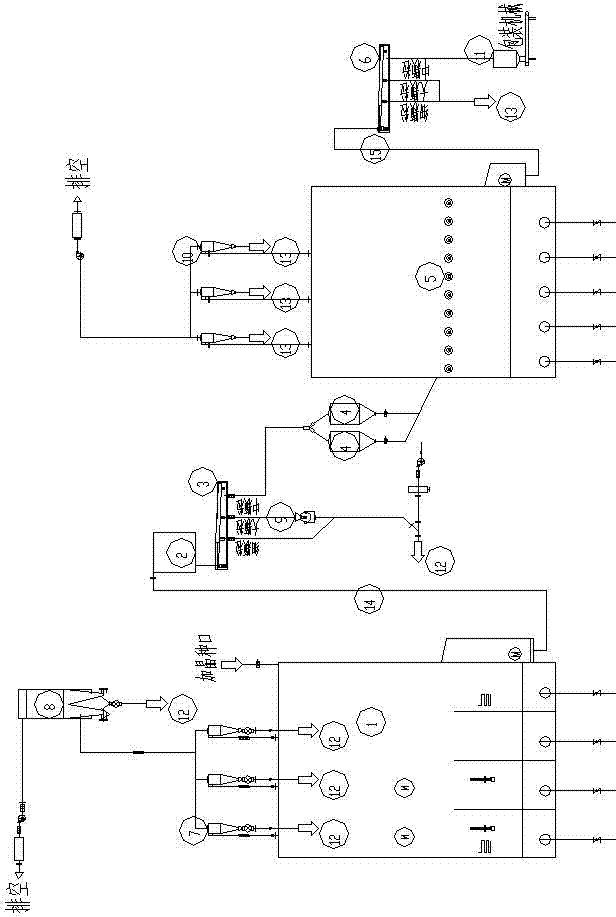

[0025] One, equipment preparation: the present invention connects production equipment to have continuous spray fluidized bed pelletizing machine 1, polishing unit 2, screening machine 3, quantitative metering device 4, fluidized bed coating machine 5, screening machine 6 etc., as figure 1 shown.

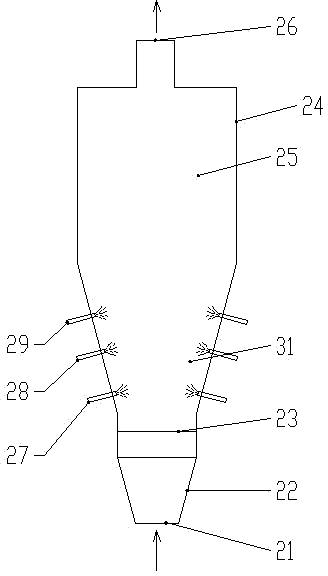

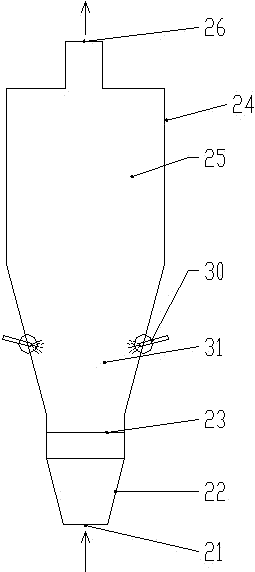

[0026] Among them, the fluidized bed coating machine 5 is an adjustable fluidized bed coating machine, and the height of the atomization zone of the spray gun increases with the increase of the fluidized material level, which can adapt to large-scale coating production, ensure that the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com