Method for preparing high-content nitrogen-doped porous carbon materia

A technology of nitrogen-doped porous carbon with high content, applied in the field of nanomaterials, can solve problems such as unsuitable for industrial applications, cumbersome and complicated process, unfriendly environment, etc., to achieve large-scale mass production, wide source of raw materials, simple and effective method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

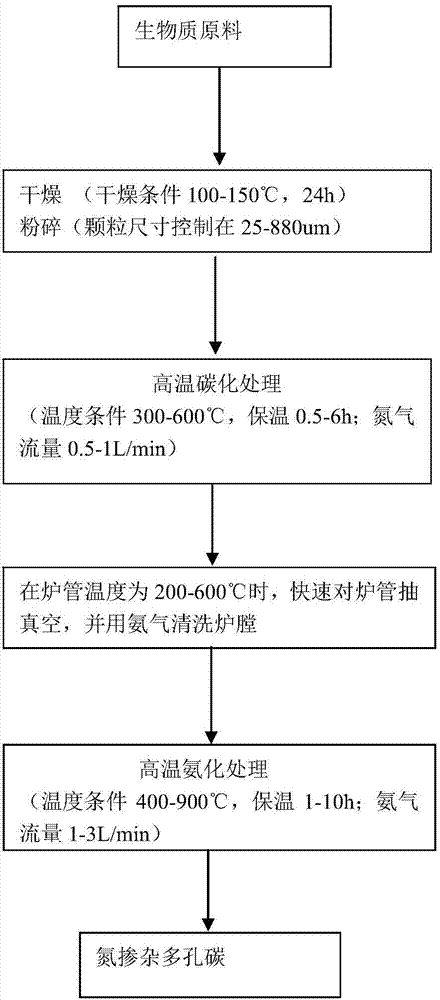

[0029] Such as figure 1 as shown, figure 1 It is a flowchart of the preparation method of the high-content nitrogen-doped porous carbon material shown in Example 1.

[0030] A method for preparing a high-content nitrogen-doped porous carbon material, comprising the following steps: placing corncobs as a raw material of biomass in a blast drying oven, drying at 100°C for at least 24 hours, and controlling the particle size after pulverization and sieving 500um, put the corn cob particles with a particle size of 500um into the material boat, and place the material boat in the atmosphere furnace; vacuumize the sealed furnace tube, and then replace it with nitrogen twice, and carry out the furnace tube under nitrogen atmosphere. Heating, the flow rate of nitrogen gas is 0.5L / min, the heating rate is 5°C / min, the temperature is slowly raised from room temperature to 400°C, the treatment time is 3 hours, and the temperature is kept at 400°C for 3h; after high-temperature carbonizat...

Embodiment 2

[0036]A method for preparing a high-content nitrogen-doped porous carbon material, comprising the following steps: placing corncobs as a raw material of biomass in a blast drying oven, drying at 100°C for at least 24 hours, and controlling the particle size after crushing and sieving to 500um, put the corn cob particles with a particle size of 500um into the material boat, and place the material boat in the atmosphere furnace; vacuumize the sealed furnace tube, and then replace it with nitrogen twice, and carry out the furnace tube under nitrogen atmosphere. Heating, the flow rate of nitrogen gas is 0.5L / min, the heating rate is 5°C / min, the temperature is slowly raised from room temperature to 300°C, the treatment time is 3 hours, and the temperature is kept at 300°C for 3h; after high-temperature carbonization treatment, when the temperature is 300°C , and then quickly evacuate the furnace tube, replace the nitrogen with ammonia for at least three times, and clean the furnace...

Embodiment 3

[0038] A method for preparing a high-content nitrogen-doped porous carbon material, comprising the following steps: placing the biomass raw material coconut shell in a blast drying oven, drying at 150°C for at least 24 hours, and controlling the particle size after crushing and sieving to 880um, put the coconut shell particles with a particle size of 880um into the material boat, and place the material boat in the atmosphere furnace; vacuumize the sealed furnace tube, and then replace it with nitrogen twice. Heating, the flow rate of nitrogen gas is 1L / min, the heating rate is 3°C / min, the temperature is slowly raised from room temperature to 300°C, the treatment time is 0.5 hours, and the temperature is kept at 300°C for 3h; after high-temperature carbonization treatment, when the temperature is 300°C, Then quickly evacuate the furnace tube, replace the nitrogen with ammonia for at least three times, and clean the furnace with ammonia; continue to program the temperature rise ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com