A method and device for continuous distillation and purification of tungsten hexafluoride

A tungsten hexafluoride and rectification technology, which is applied in tungsten halide, vacuum distillation, etc., can solve the problems of low production efficiency, high cost, and difficult application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

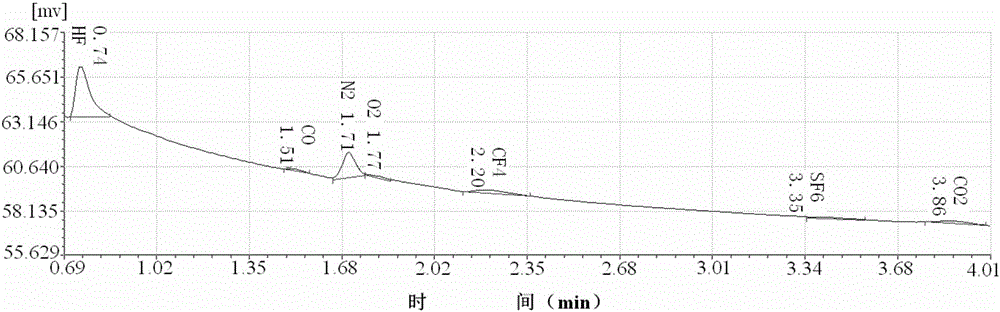

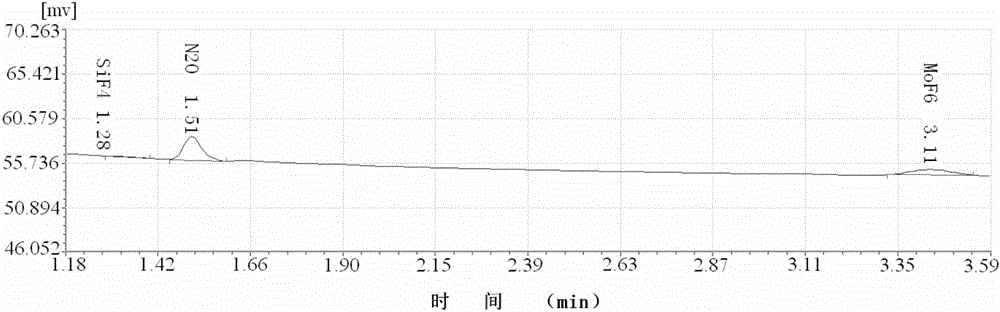

[0093] Raw materials: the content of tungsten hexafluoride gas to be purified is 99.95%, and the content of impurities is shown in Table 1, which shows the content of impurities in the raw materials used in Example 1 of the present invention.

[0094] The impurity content in the raw material that table 1 embodiment of the present invention 1 adopts

[0095] components

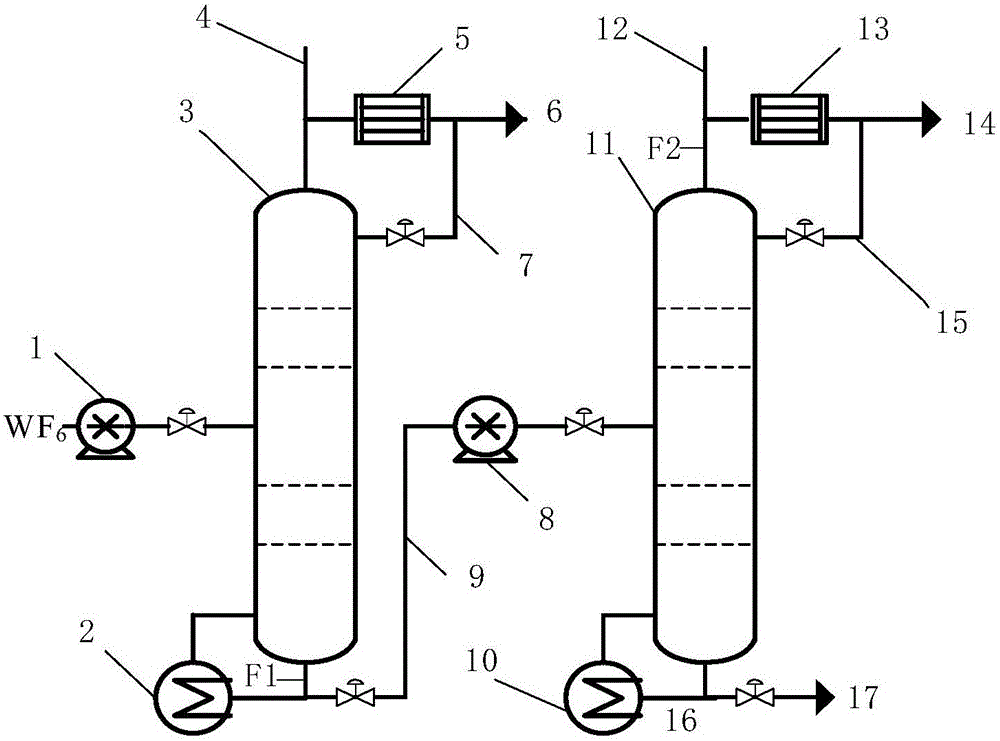

[0096] Distillation unit: using figure 1 In the rectification device of the shown structure, wherein, the light removal tower 3 is 3000mm high, 500mm in diameter, and the number of trays is 30, with a built-in diameter of 5mm stainless steel θ ring packing; the weight removal tower 11 is 3000mm high, 500mm in diameter, and the number of trays is 40, Built-in diameter 5mm stainless steel θ ring packing. The body of light removal tower 3 and weight removal tower 11 as well as the reboiler, condenser and piping are made of stainless steel.

[0097] Distillation process:

[0098] Step 1: If figure 1 A...

Embodiment 2

[0107] Raw material: the content of tungsten hexafluoride gas to be purified is 99.99%, and the content of impurities is shown in Table 3, which shows the content of impurities in the raw materials used in Example 2 of the present invention.

[0108] The impurity content in the raw material that table 3 embodiment of the present invention 2 adopts

[0109] components

N 2

o 2 +Ar

CO

CO 2

SF 6

SiF 4

CF 4

MoF 6

N 2 o

HF

Content (×10 -6 )

10

8

9

4

3

2

7

12

5

35

[0110] Distillation unit: using figure 1 The rectification device of the shown structure, wherein, the weight removal tower 3 is 0.5m high, 0.1m in diameter, the number of trays is 20, and the built-in diameter is 1mm polytetrafluoroethylene Raschig ring packing; the weight removal tower 11 is 0.5m high, and the diameter is 0.1 m, the number of trays is 20, and the built-in PTFE Raschig ring packing with...

Embodiment 3

[0120] Raw material: the content of tungsten hexafluoride gas to be purified is 99%, and the impurity content is shown in Table 5, and Table 5 shows the impurity content in the raw material used in Example 3 of the present invention.

[0121] The impurity content in the raw material that table 5 embodiment of the present invention 3 adopts

[0122] components

N 2

o 2 +Ar

CO

CO 2

SF 6

SiF 4

CF 4

MoF 6

N 2 o

HF

Content (×10 -6 )

2500

1800

900

400

300

200

700

1200

500

1500

[0123] Distillation unit: using figure 1 In the rectification device of the shown structure, wherein, the weight removal tower 3 is 15000mm high, 3000mm in diameter, and the number of trays is 80, with a built-in diameter of 100mm stainless steel Pall ring packing; the weight removal tower 11 is 15000mm high, 3000mm in diameter, and the number of trays is 80, built-in diameter 100mm stainles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com