a water blocking agent

A technology of water blocking agent and brine, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of temperature resistance, salt resistance, low jelly strength, etc., and achieve strong temperature resistance and salt resistance, Good water blocking effect and high gel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

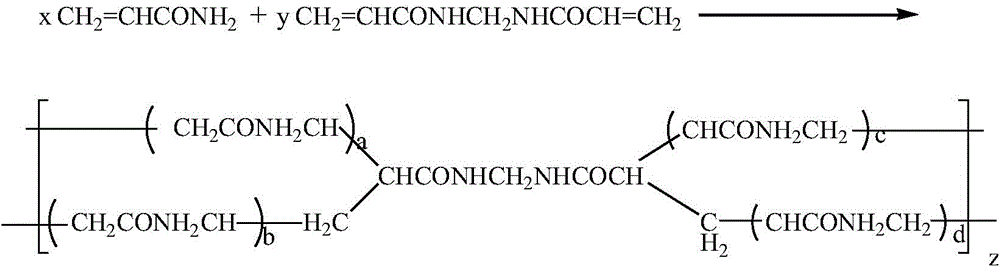

Method used

Image

Examples

Embodiment 1

[0046] Stir and dissolve 7g of acrylamide, 4g of acrylic acid, 0.005g of N,N'-methylenebisacrylamide, 1.3g of sodium hydroxide, and 0.008g of ammonium persulfate into 60g of brine containing 23% sodium chloride, and slowly raise the temperature to 80°C and keep warm at this temperature. After 4.5 hours, the reaction produces a high-strength gel water blocking agent; the water absorption rate of this water blocking agent is 85g / g.

[0047] Test Conditions:

[0048] Under the conditions of test temperature 27°C, constant frequency f=1Hz, constant stress τ=100Pa, time t=3~5min, the original thickness of the sample is 6mm, and the test gap is 3mm.

[0049] Test Results:

[0050] With the increase of shear time, the storage modulus G' basically remains unchanged, G' fluctuates around 4580Pa, and the dissipation modulus G" is stable in the range of 350-360Pa. Under this condition, the viscoelasticity of the gel does not occur changes, the gel structure was not destroyed.

[0051...

Embodiment 2

[0053] Dissolve 10g of acrylamide, 0.01g of N,N'-methylenebisacrylamide, and 0.008g of azobisisobutyronitrile in 74g of brine containing 21% sodium chloride and 2% calcium chloride, and slowly heat up to 80 ℃, and keep warm at this temperature. After 4.5 hours, the reaction produces a high-strength gel water blocking agent; the water absorption rate of this water blocking agent is 87g / g.

[0054] Test Conditions:

[0055] Under the conditions of test temperature 27°C, constant stress τ=100Pa, scanning time t=3~5min, constant frequency f=1Hz, the sample thickness is 5mm and the gap is 3mm.

[0056] Test Results:

[0057] With the increase of shear time t, the storage modulus G' does not change, G'=12220Pa. The dissipation modulus G" is stable at 336-337Pa. It shows that under this condition, the viscoelasticity of the gel does not change, and the gel structure is not destroyed.

Embodiment 3

[0059] Dissolve 10g of acrylamide, 0.01g of N,N'-methylenebisacrylamide, and 0.008g of azobisisobutyronitrile in 130g of brine containing 21% sodium chloride and 2% calcium chloride, and slowly heat up to 80 ℃, and keep warm at this temperature. After 5 hours, the reaction produces a high-strength gel water blocking agent; the water absorption rate of this water blocking agent is 80g / g.

[0060] Test Conditions:

[0061] Under the conditions of test temperature 27°C, constant frequency f=1Hz, constant stress τ=100Pa, time t=3~5min, the original thickness of the sample is 6mm, and the test gap is 4mm.

[0062] Test Results:

[0063] With the increase of shearing time, the storage modulus G' is basically unchanged, G' fluctuates around 7080Pa, and the dissipation modulus G" is stable in the range of 410-420Pa. It shows that under this condition, the viscoelasticity of the gel is not stable. Changes occurred, the gel structure was not destroyed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com