A method for the production of d-tagatose based on the in situ coupling of enzymatic isomerization and continuous chromatographic separation

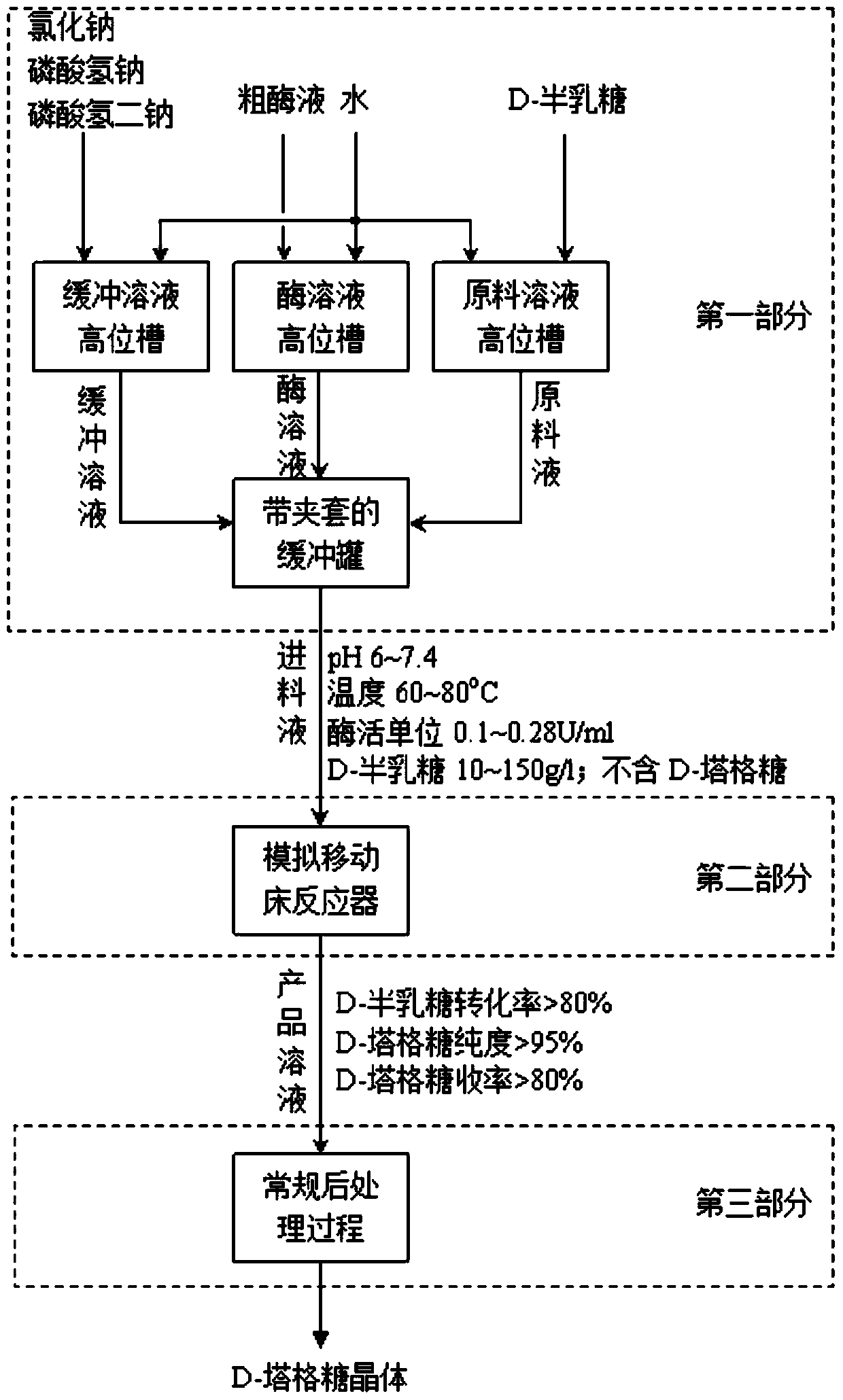

A technology of continuous chromatography and production method, applied in the field of D-tagatose production, can solve the problems that cannot be used to improve the conversion rate of D-galactose to D-tagatose, and cannot change the chemical balance, so as to overcome the feedback Inhibiting effect, reducing equipment costs, reducing the effect of operating units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

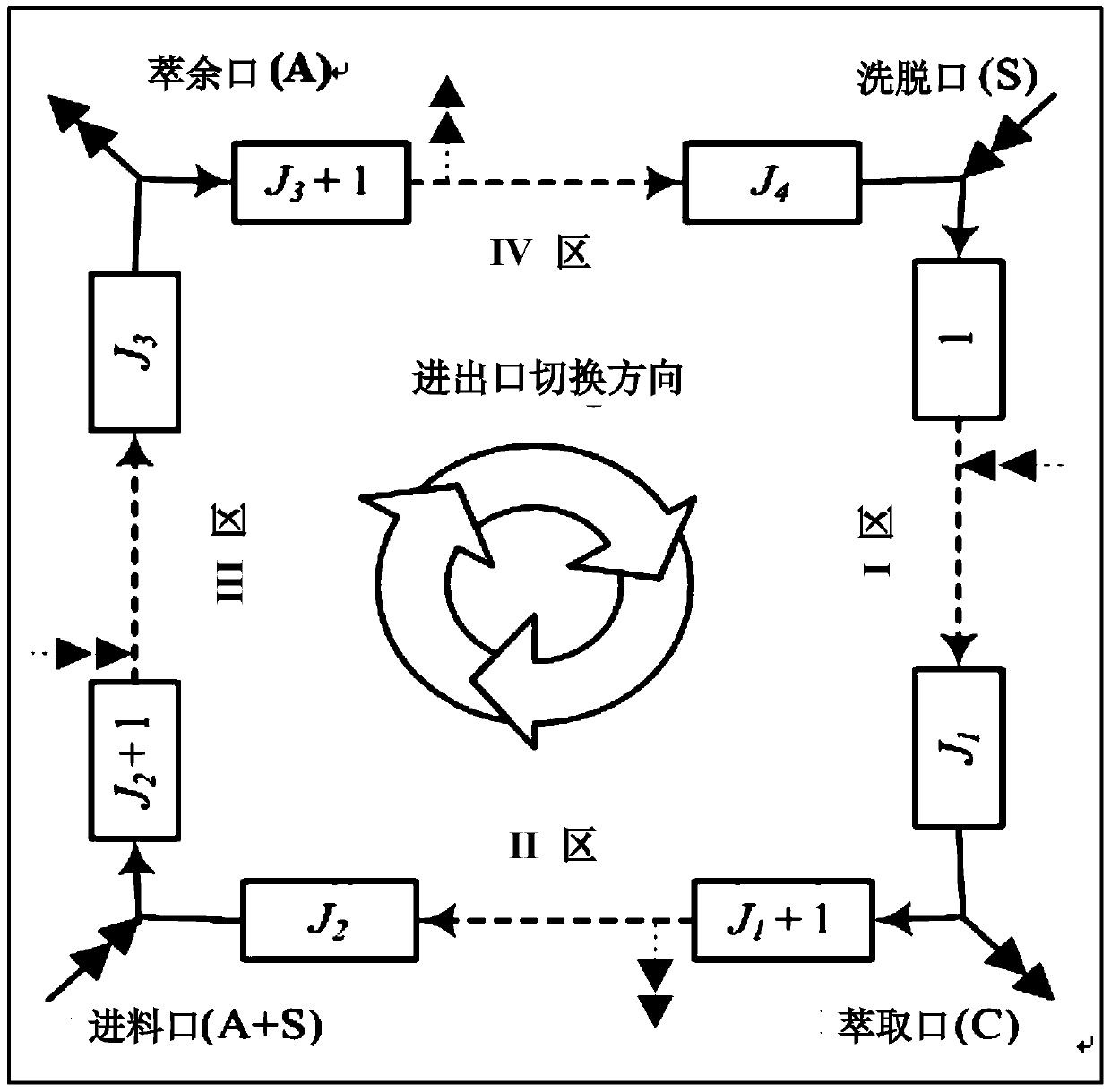

Method used

Image

Examples

Embodiment 1

[0066] Operating conditions: the concentration of D-galactose in the feed liquid is 10 g / l, the enzyme activity unit is 0.1 U / ml, and the pH value is 6; preheating temperature, 60°C; column temperature, 60°C; column number and distribution, 8, 2 / 2 / 2 / 2 distribution; switching time, 60 min; flow rate in zone I is 1.4, flow rate in zone II is 0.8, flow rate in zone III is 0.807, and flow rate in zone IV is 0.4.

[0067] Results: The feed liquid treatment rate was 0.59 ml / min, the conversion rate of D-galactose was 82.9%, the yield of D-tagatose was 82.0%, and the purity of D-tagatose in the product solution was 99.5%.

Embodiment 2

[0069] Operating conditions: the concentration of D-galactose in the feed liquid is 10 g / l, the enzyme activity unit is 0.18 U / ml, and the pH value is 7.4; preheating temperature, 70°C; column temperature, 70°C; column number and distribution, 8, 1 / 3 / 3 / 1 distribution; switching time, 80 min; flow rate in zone I is 1.35, flow rate in zone II is 0.4, flow rate in zone III is 0.6, and flow rate in zone IV is 0.4.

[0070] Results: The feed liquid treatment rate was 12.7 ml / min, the conversion rate of D-galactose was 94.8%, the yield of D-tagatose was 94.8%, and the purity of D-tagatose in the product solution was 95.0%.

Embodiment 3

[0072]Operating conditions: the concentration of D-galactose in the feed solution is 100 g / l, the enzyme activity unit is 0.28 U / ml, and the pH value is 7; preheating temperature, 80°C; column temperature, 80°C; column number and distribution, 16, 2 / 6 / 6 / 2 distribution; switching time, 80 min; flow rate in zone I is 1.35, flow rate in zone II is 0.5, flow rate in zone III is 0.93, and flow rate in zone IV is 0.35.

[0073] Results: The feed liquid treatment rate was 27.3 ml / min, the conversion rate of D-galactose was 81.6%, the yield of D-tagatose was 80.9%, and the purity of D-tagatose in the product solution was 95.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com