LED straight tube lamp and inner coating thereof

A technology of LED straight tube lamp and straight tube, applied in coating, lampshade, luminous paint, etc., can solve the problems affecting the service life of LED straight tube lamp, poor heat dissipation effect of LED straight tube lamp, etc. Reduce electricity bills, uniform lighting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The coating in the LED straight tube lamp, according to the mass percentage, includes 48.67% calcium halophosphate phosphor, 0.3% sodium stilbene biphenyl disulfonate, 32% butyl acetate, 3% defoamer, 0.03% leveling agent, 16% epoxy resin; the comprehensiveness of the coating in this embodiment is the best.

Embodiment 2

[0019] The coating in the LED straight tube lamp, according to the mass percentage, includes 46.45% calcium halophosphate phosphor, 0.5% sodium stilbene biphenyl disulfonate, 32% butyl acetate, 5% defoamer, 0.05% leveling agent, 16% epoxy resin; this ratio of coating heat dissipation effect can be improved by 15%, and the lighting effect is also the best.

Embodiment 3

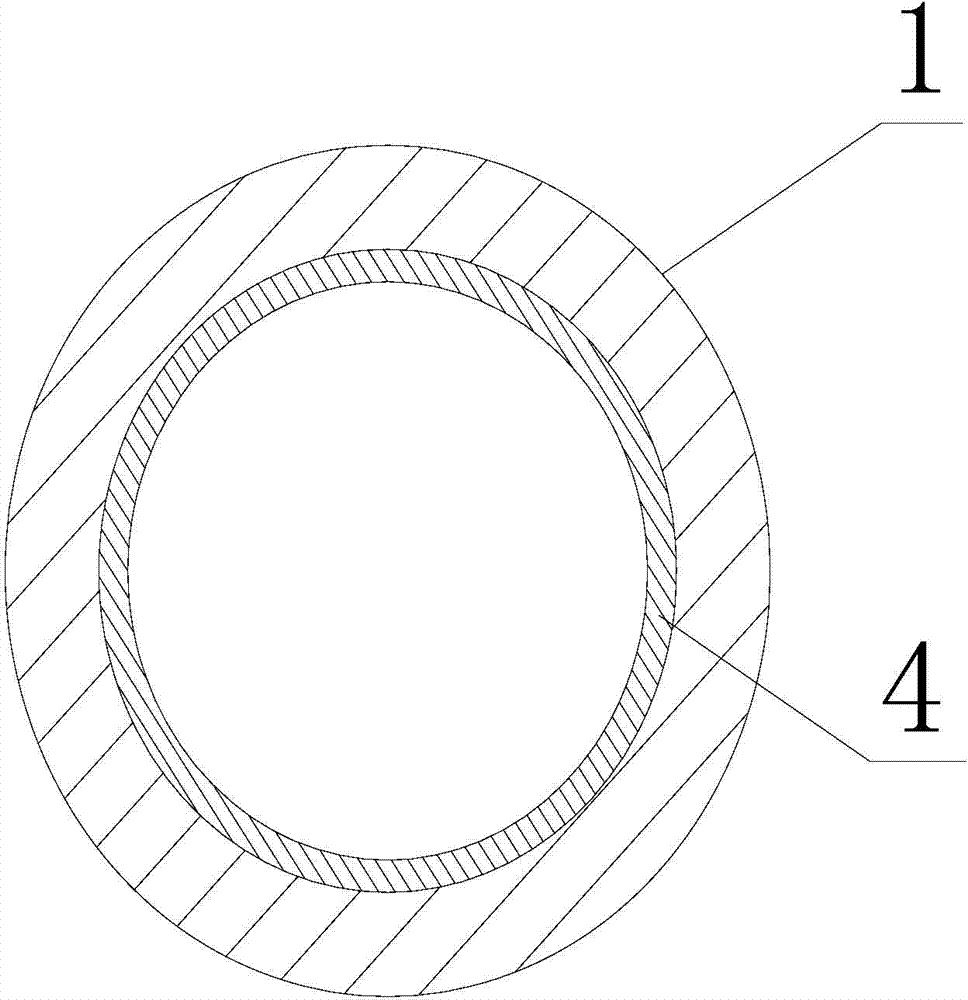

[0021] The coating in the LED straight tube lamp, according to the mass percentage, includes 50% calcium halophosphate phosphor, 0.3% sodium stilbene biphenyl disulfonate, 31% butyl acetate, 3.67% defoamer, 0.03% leveling agent, 15% epoxy resin; see figure 2 , the bonding effect between the coating 4 and the straight tube lampshade 3 in this embodiment is the best.

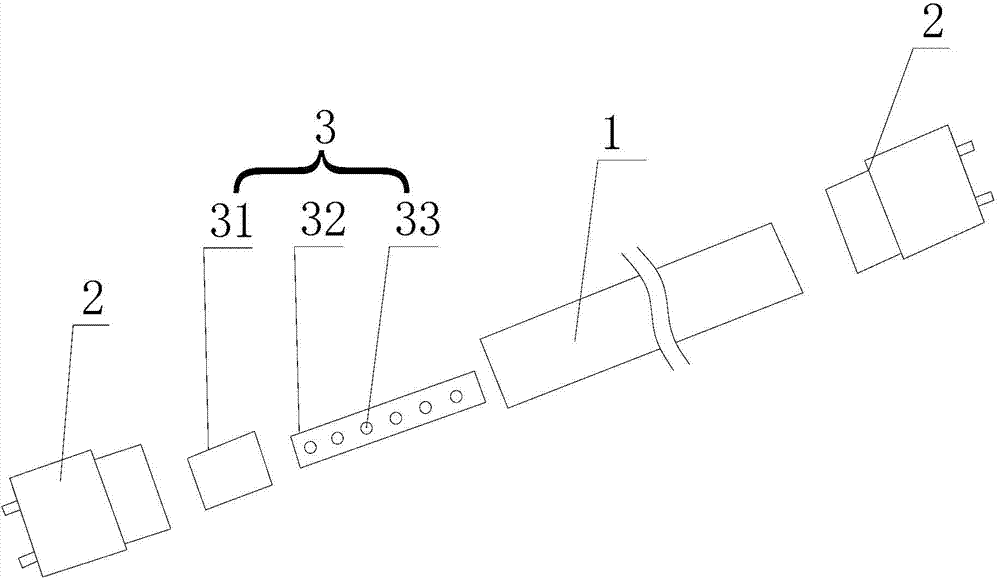

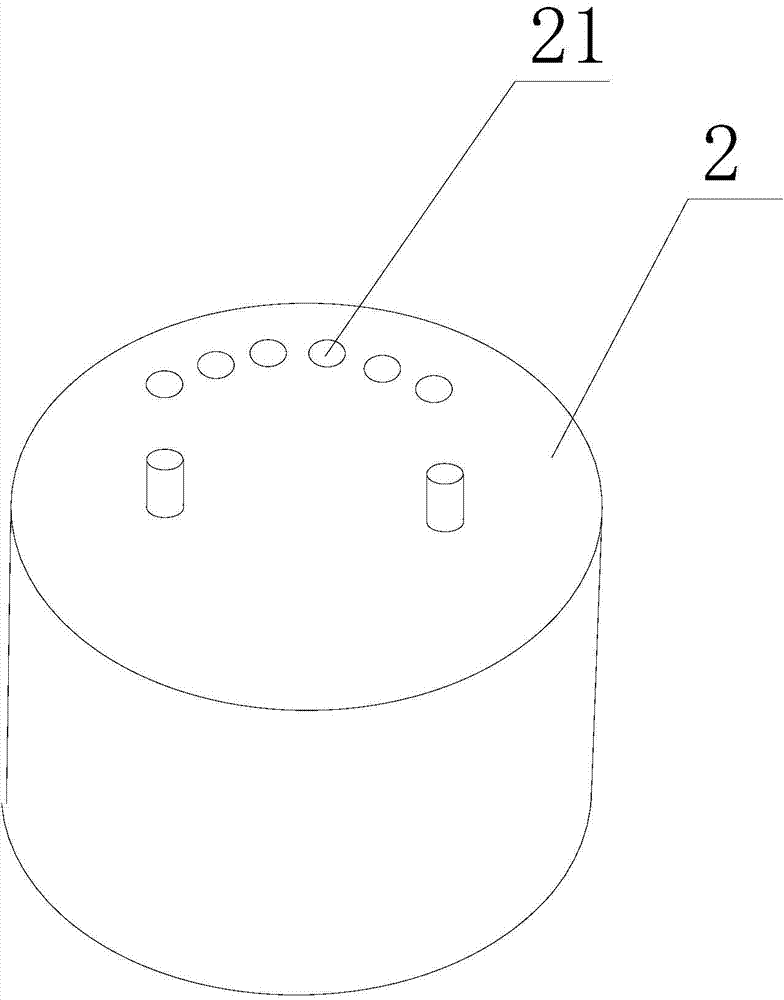

[0022] The invention uses radiation to dissipate heat, and the heat dissipation effect is improved by 10% to 15% compared with the common coating heat dissipation effect, and the light is uniform without ghosting, without glare, soft visual effect, and does not contain harmful substances such as mercury and does not pollute the environment; light transmittance High, good lighting effects, compared with other lamps, save electricity, can reduce electricity costs; the lamp cap is equipped with cooling holes, good heat dissipation effect, the place where the straight tube lampshade matches the lamp cap is not coated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com