Radiating tube of oil radiator and production method thereof

A technology of oil radiator and production method, applied in the direction of heat exchanger shell, tubular element, heat exchange equipment, etc., can solve the problems of reducing performance and service life of radiator, high working pressure of hydraulic system, short service life, etc. Achieve the effect of reducing material cost, large heat dissipation and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

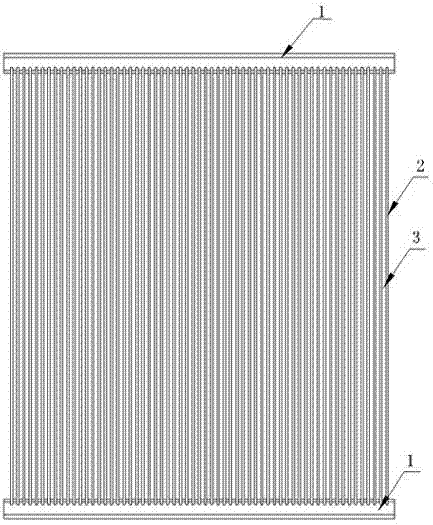

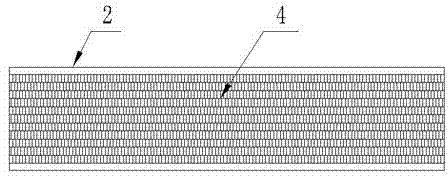

[0014] Embodiment 1, a kind of heat dissipation pipe of oil radiator, refer to figure 1 , figure 2 , the two ends of the heat dissipation pipe 2 are clamped on the main piece 1 and put into a continuous brazing furnace for nitrogen protection brazing to form a whole. The heat dissipation belt 3 is installed between the two heat dissipation pipes 2, and fins are installed in the heat dissipation pipe 2. 4. The fins 4 are in contact with the inner wall of the heat dissipation pipe 2, which constitutes a structure of the present invention;

[0015] The heat dissipation pipes of the above-mentioned oil radiators are produced by the following method: first, the fins 4 are installed in the heat dissipation pipes 2, and then the heat dissipation pipes 2 and the heat dissipation strips 3 are laid out in sequence, and a heat dissipation strip 3 is laid in sequence, and a heat dissipation pipe is laid on the front and back respectively. 2. Arrange neatly on the assembly table, use a f...

Embodiment 2

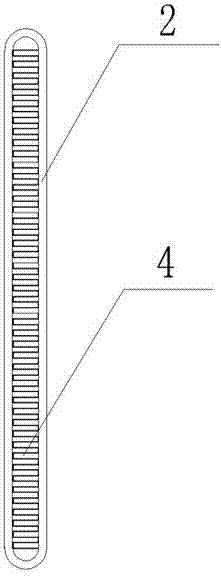

[0016] Embodiment 2, a kind of heat dissipation pipe of oil radiator, refer to figure 1 , figure 2 , image 3 , on the basis of Example 1, the radiating pipe 2 is in the shape of an oval flat tube, and the radiating pipe 2 is formed by high-frequency welding of an aluminum sheet without a composite layer, and the wall thickness is between 0.5mm and 1.0mm. Example 1 is exactly the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com