Ultrasonic surface wave nonlinear detection method for roll fatigue hardening layer

A technology of fatigue hardening layer and ultrasonic surface wave, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc. It can solve the problems of heavy workload, poor accuracy, and unsuitability for fatigue hardening layer, so as to save production cost and ensure production Safe, accurate and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

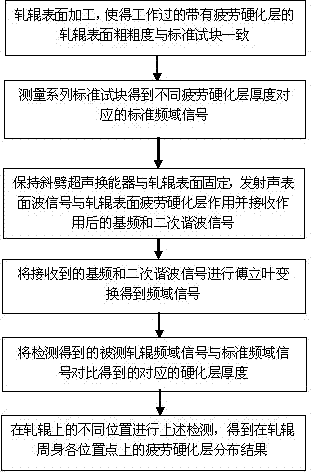

[0023] Such as figure 1 Shown, a kind of ultrasonic surface wave nonlinear detection method of roll fatigue hardening layer, comprises the following steps:

[0024] Step 1, prepare a series of standard test blocks with different fatigue hardened layer thicknesses, the thickness of the fatigue hardened layer on the series standard test blocks is known;

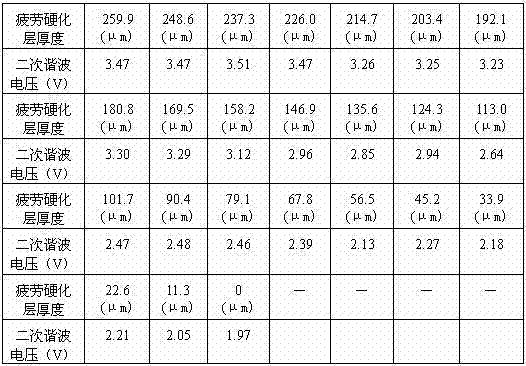

[0025] Step 2. Use the surface acoustic wave to detect the series of standard test blocks through the wedge ultrasonic transducer to obtain a series of fundamental frequency and second harmonic signals corresponding to the series of standard test blocks one by one, and the series of fundamental frequency Perform Fourier transform with the second harmonic signal to obtain a series of standard frequency domain signals corresponding to the series of standard test blocks one by one, and the series of standard frequency domain signals are the standard frequency domain signals of the fatigue hardened layer corresponding to the thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com